Importance of Proper Battery Hookup

Proper battery hookup is crucial for the efficient and safe operation of electrical systems, especially in applications such as automotive, marine, and off-grid power systems. The way batteries are connected can significantly impact their performance and lifespan. Here's why it's important to pay close attention to battery hookup:

-

Optimized Performance: Correctly connecting the batteries ensures that the electrical current flows smoothly and consistently through the system. This optimized performance is essential for powering various electrical components and devices, preventing voltage drops and ensuring a steady power supply.

-

Enhanced Safety: Proper battery hookup reduces the risk of electrical hazards such as short circuits, overloading, and overheating. It also minimizes the potential for accidents, ensuring a safe operating environment for both the equipment and individuals involved.

-

Extended Battery Life: When batteries are connected correctly, they are less likely to experience issues such as uneven charging, sulfation, and premature degradation. This ultimately extends the lifespan of the batteries, reducing the frequency of replacements and saving costs in the long run.

-

Improved Efficiency: A well-planned battery hookup minimizes energy losses and maximizes the efficiency of the entire electrical system. This is particularly important in off-grid and alternative energy systems where every bit of energy is valuable.

-

Compliance with Standards: Following best practices for battery hookup ensures compliance with industry standards and regulations, which is essential for automotive, marine, and other applications where safety and reliability are paramount.

In essence, proper battery hookup is not only about connecting cables and terminals; it's about ensuring the overall performance, safety, and longevity of the electrical system. By understanding the significance of correct battery hookup, individuals and businesses can make informed decisions and take the necessary steps to optimize their electrical setups.

Understanding Cable Connection Terminology

Before delving into the intricacies of battery hookup, it’s essential to grasp the fundamental terminology associated with cable connections. This knowledge forms the basis for selecting the right cables and connectors for a specific application. Here are key terms to understand:

-

Conductors: These are the metal wires within the cable that carry the electrical current. The size and material of the conductors significantly impact the cable’s capacity to carry current without overheating.

-

Stranding: This refers to the number of smaller wires twisted together to form a single conductor. More strands provide flexibility and durability, crucial for applications where the cable may undergo bending or movement.

-

Gauge: The gauge of a cable indicates the diameter of its conductors. Lower gauge numbers represent thicker wires, capable of handling higher currents. Understanding gauge is essential for selecting cables that can accommodate the electrical load without overheating.

-

Insulation: Insulation materials surround the conductors, providing protection from external elements and preventing electrical leakage. Different types of insulation are designed for specific environments and temperature ranges.

-

Terminals and Connectors: These are the end points of the cables used for making electrical connections. Understanding the various types of terminals and connectors, such as ring terminals, spade terminals, and quick-connect terminals, is crucial for secure and reliable battery hookup.

By familiarizing oneself with these cable connection terms, individuals can make informed decisions when selecting cables and connectors for battery hookup. Understanding the nuances of conductors, stranding, gauge, insulation, and terminals empowers users to choose the most suitable components for their specific electrical systems.

Selecting the Right Cable for Battery Hookup

Choosing the appropriate cables for battery hookup is a critical aspect of ensuring a reliable and efficient electrical system. Several factors must be considered when selecting cables to facilitate optimal battery connections:

-

Wire Gauge: The gauge of the cable is a key consideration, as it determines the maximum current-carrying capacity. For battery hookup, it’s essential to use cables with an adequate gauge to handle the expected electrical load without overheating. Thicker cables (lower gauge numbers) are suitable for high-current applications, while thinner cables (higher gauge numbers) are ideal for low-current connections.

-

Stranding and Flexibility: Cables with a higher number of strands offer greater flexibility, making them suitable for applications where the cable may undergo bending or movement. Flexibility is crucial for battery hookup, especially in automotive and marine environments where vibrations and mechanical stress are common.

-

Insulation Material: The insulation material of the cable should be selected based on the environmental conditions and potential exposure to chemicals, moisture, and extreme temperatures. Heat-resistant and durable insulation is essential for maintaining the integrity of the cables and ensuring long-term reliability.

-

Terminal Compatibility: Consideration should be given to the type of terminals and connectors used for battery hookup. The cable’s compatibility with ring terminals, spade terminals, or other connector types must be assessed to ensure secure and reliable connections.

-

Compliance with Standards: It’s imperative to select cables that comply with industry standards and regulations, especially in applications where safety and reliability are paramount. Compliance ensures that the cables meet the necessary requirements for performance and safety.

By carefully considering these factors, individuals and businesses can make informed decisions when selecting cables for battery hookup. The right cables not only facilitate efficient electrical connections but also contribute to the overall safety and reliability of the system.

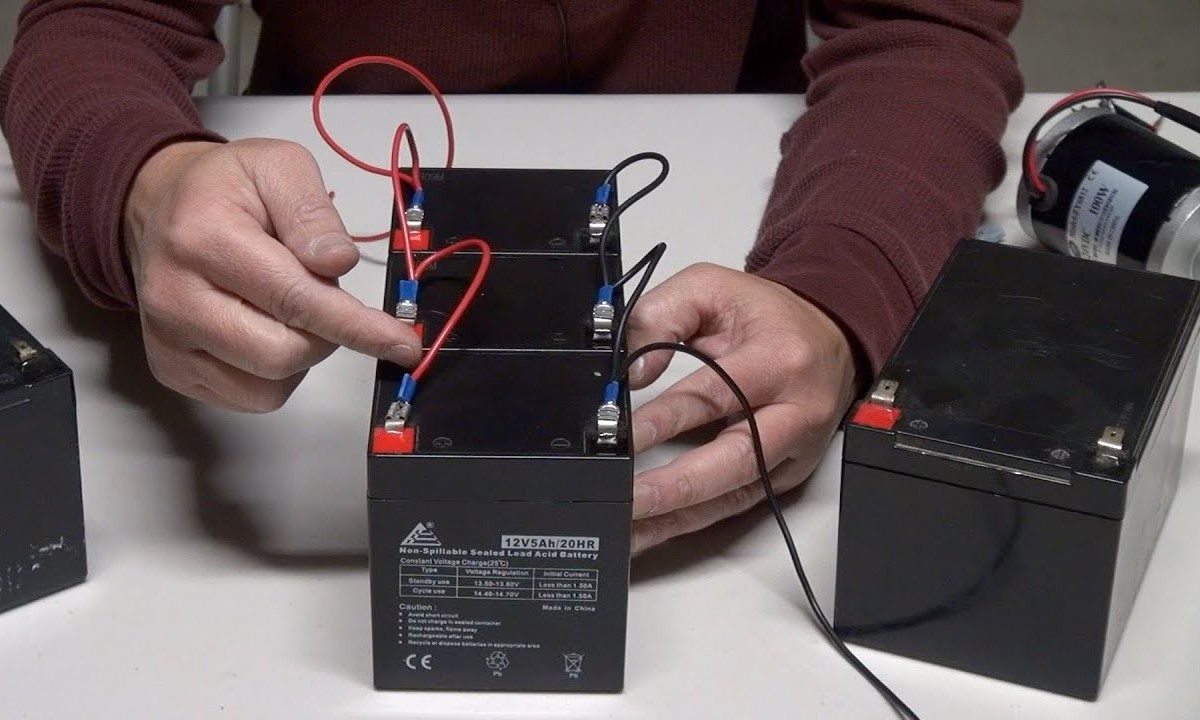

Best Practices for Connecting Cables to Batteries

Properly connecting cables to batteries is essential for ensuring reliable and safe electrical systems. Adhering to best practices during the battery hookup process can prevent issues such as poor conductivity, overheating, and potential safety hazards. Here are the best practices for connecting cables to batteries:

-

Clean and Inspect Terminals: Before connecting the cables, it’s crucial to clean the battery terminals to remove any corrosion or debris. Inspecting the terminals for damage and ensuring they are in good condition is essential for establishing secure and reliable connections.

-

Use Correct Cable Lengths: Selecting the appropriate cable lengths minimizes unnecessary slack and reduces the risk of cable damage or entanglement. Properly sized cables also contribute to efficient electrical conductivity.

-

Apply Dielectric Grease: Applying dielectric grease to the battery terminals before making the connections helps prevent corrosion and enhances conductivity. This protective measure is particularly beneficial in environments prone to moisture and corrosion.

-

Secure and Tighten Connections: Ensuring that the cable connections are securely fastened to the battery terminals is essential for preventing loose or intermittent connections. Properly tightening the connections minimizes resistance and prevents potential arcing or overheating.

-

Utilize Insulated Tools: When making the cable connections, using insulated tools reduces the risk of accidental short circuits and electrical hazards. Insulated tools help maintain a safe working environment during the battery hookup process.

-

Follow Sequence and Polarity: Adhering to the correct sequence and polarity when connecting the cables is crucial for preventing electrical issues and potential damage to the system. Following the manufacturer’s guidelines for the specific battery hookup sequence is essential.

By following these best practices, individuals can ensure that the battery hookup process is conducted with precision and attention to detail. Implementing these practices contributes to the overall reliability, safety, and performance of the electrical system.

Safety Precautions for Battery Hookup

When dealing with battery hookup, prioritizing safety is paramount to prevent accidents, injuries, and damage to the electrical system. Adhering to safety precautions not only safeguards individuals involved in the installation process but also contributes to the long-term reliability of the system. Here are essential safety measures to consider during battery hookup:

-

Eye and Skin Protection: Wear safety glasses and gloves to protect against potential exposure to corrosive materials, electrical sparks, and accidental contact with battery terminals. Safety goggles and gloves mitigate the risk of eye injuries and skin irritation.

-

Ventilation: Ensure adequate ventilation in the battery installation area to disperse any fumes emitted during the hookup process. Proper ventilation reduces the concentration of potentially harmful gases and promotes a safer working environment.

-

Avoid Smoking and Open Flames: Prohibit smoking and the presence of open flames near the battery hookup area to prevent the risk of ignition from flammable gases emitted by the batteries. Adhering to a strict no-smoking policy reduces the potential for fire hazards.

-

Disconnect Power Sources: Prior to initiating the battery hookup, disconnect all power sources and turn off electrical systems to minimize the risk of electrical shock and short circuits. This precaution ensures a safer working environment during the installation process.

-

Handle Batteries Carefully: Lift and handle batteries with caution to avoid strain and potential injuries. Using proper lifting techniques and handling equipment reduces the risk of back injuries and accidents during the transportation and installation of batteries.

-

Prevent Short Circuits: Avoid placing metal tools or objects across the battery terminals to prevent accidental short circuits. Using insulated tools and following the correct sequence for cable connections minimizes the risk of short circuiting the batteries.

By adhering to these safety precautions, individuals can create a safer and more secure environment during the battery hookup process. Prioritizing safety not only protects those involved but also contributes to the overall success and reliability of the electrical installation.

Common Mistakes to Avoid in Battery Hookup

During the battery hookup process, certain common mistakes can lead to performance issues, safety hazards, and potential damage to the electrical system. By being aware of these mistakes and taking proactive measures to avoid them, individuals can ensure a successful and trouble-free battery installation. Here are common mistakes to steer clear of in battery hookup:

-

Using Incorrect Cable Gauge: Selecting cables with inadequate gauge for the electrical load can lead to overheating, voltage drops, and inefficient power transmission. It’s crucial to match the cable gauge to the specific current requirements to avoid performance issues.

-

Improper Terminal Cleaning: Neglecting to clean the battery terminals before making connections can result in poor conductivity, increased resistance, and potential corrosion. Thoroughly cleaning and inspecting the terminals is essential for reliable and secure connections.

-

Overlooking Polarity and Sequence: Failing to adhere to the correct polarity and sequence when connecting the cables can lead to electrical issues, potential damage to equipment, and safety hazards. Following the manufacturer’s guidelines for the hookup sequence is crucial.

-

Underestimating Cable Length: Using cables that are too short may strain the connections and limit flexibility, while excessively long cables can lead to entanglement and potential damage. Selecting the appropriate cable lengths is essential for a well-organized and reliable battery hookup.

-

Ignoring Safety Precautions: Disregarding safety measures such as eye protection, ventilation, and handling precautions can lead to injuries, exposure to hazardous materials, and unsafe working conditions. Prioritizing safety is crucial for a successful and secure battery hookup process.

-

Using Incorrect Tools: Using non-insulated tools or inappropriate equipment during the installation can result in accidental short circuits, electrical shocks, and damage to the batteries. Utilizing the correct tools and equipment minimizes the risk of safety hazards.

By being mindful of these common mistakes and taking proactive steps to avoid them, individuals can ensure a smooth and effective battery hookup process. Awareness of potential pitfalls contributes to the overall success and reliability of the electrical installation.

Tips for Maintaining Battery Cable Connections

Maintaining proper battery cable connections is essential for the long-term reliability and performance of electrical systems. Regular inspection and maintenance help prevent issues such as corrosion, poor conductivity, and premature wear, ensuring the continued efficiency of the battery hookup. Here are valuable tips for maintaining battery cable connections:

-

Regular Inspection: Periodically inspect the battery cable connections to check for signs of corrosion, loose connections, or damage. Early detection of issues allows for timely intervention and prevents potential performance degradation.

-

Cleaning and Corrosion Prevention: Clean the battery terminals and cable connectors to remove any corrosion or buildup. Applying a corrosion inhibitor or dielectric grease after cleaning helps prevent future corrosion and ensures optimal conductivity.

-

Tightening Connections: Ensure that the cable connections are securely fastened to the battery terminals. Periodically check for any loosening and retighten the connections as necessary to maintain proper electrical contact.

-

Applying Protective Coating: Consider using a protective coating or insulating spray on the battery cable connections to shield them from environmental elements and minimize the risk of corrosion. This additional layer of protection contributes to the longevity of the connections.

-

Monitoring Cable Flexibility: Regularly assess the flexibility of the cables to identify any signs of wear or fatigue. Stiff or brittle cables may indicate the need for replacement to maintain optimal performance and prevent potential damage.

-

Temperature and Environment Consideration: Be mindful of the temperature and environmental conditions in which the battery cable connections are situated. Extreme temperatures and exposure to harsh chemicals or moisture can impact the integrity of the connections, necessitating proactive maintenance measures.

By implementing these maintenance tips, individuals can ensure that the battery cable connections remain in excellent condition, promoting the longevity and reliability of the electrical system. Regular maintenance not only prevents performance issues but also contributes to a safe and efficient operational environment.