Y Strainer Definition

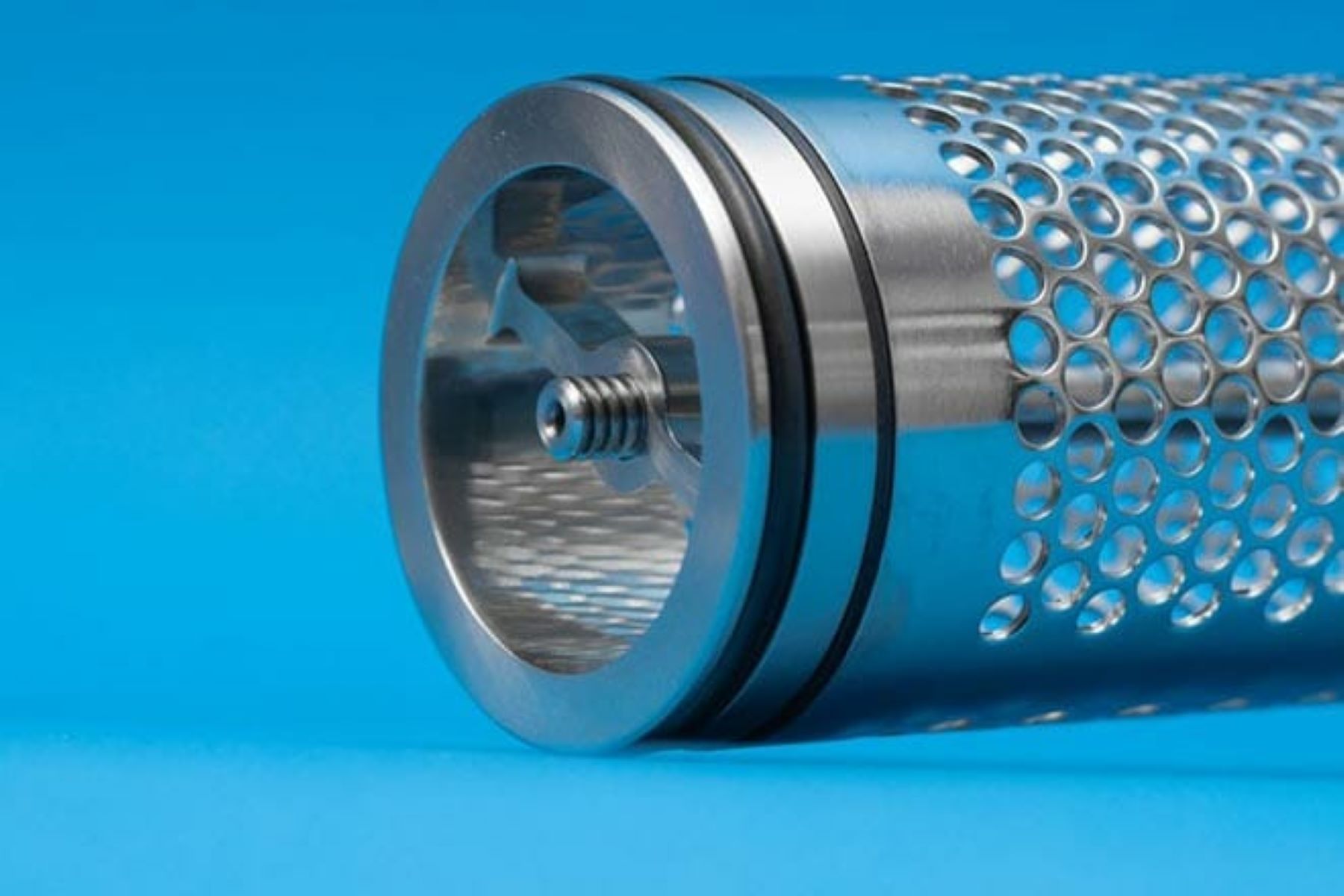

A Y strainer is a type of plumbing device that is designed to remove unwanted debris and particles from a fluid flow system. It is named after its distinctive shape, resembling the letter “Y”, and is commonly used in plumbing systems to protect downstream equipment such as valves, pumps, and nozzles from clogging and damage.

The main purpose of a Y strainer is to act as a filter, catching and trapping solid particles that may be present in the fluid being transported. These particles can include debris, dirt, scale, rust, and other contaminants that can cause blockages and impair the performance of the system.

The Y strainer is typically installed in the pipeline and is positioned in such a way that the fluid flows through it. As the fluid passes through the strainer, a perforated screen or mesh captures the unwanted particles, allowing the clean fluid to pass through and continue down the pipeline.

Y strainers are commonly made of materials such as stainless steel, brass, or cast iron, depending on the specific application and the type of fluid being filtered. The size of the strainer may vary depending on the flow rate and the diameter of the pipeline, with larger systems requiring larger strainers to accommodate the volume of fluid passing through.

These strainers are often equipped with a drain valve or blowdown valve at the bottom, which can be opened to flush out the collected debris periodically. This maintenance process helps to ensure the continued efficiency and performance of the Y strainer.

Overall, the Y strainer is an essential component in plumbing systems, especially in industrial settings where the presence of solid particles is more common. By effectively removing debris from the fluid flow, Y strainers help to protect valuable equipment, maintain proper flow rates, and minimize system downtime.

How Does a Y Strainer Work?

A Y strainer works on a simple yet effective principle to remove unwanted debris and particles from a fluid flow system. The design of the strainer allows it to trap solid particles while allowing the clean fluid to pass through smoothly.

The working mechanism of a Y strainer can be described in the following steps:

- Fluid Entry: The fluid enters the Y strainer through the inlet port. This is where the fluid flow begins within the strainer.

- Flow Diversion: Once the fluid enters the strainer, it encounters a diverter plate or baffle. This component helps to redirect the flow and guide it towards the straining element.

- Straining Element: The core component of the Y strainer is the straining element, which is typically a perforated screen or mesh. This screen or mesh is strategically positioned in the Y-shaped chamber to capture and retain any solid particles present in the fluid.

- Particle Capture: As the fluid flows through the straining element, any solid particles larger than the size of the perforations get trapped. These particles can include debris, dirt, rust, scale, and other contaminants that could potentially cause clogs and damage downstream equipment.

- Clean Fluid Passage: After the solid particles are captured, the clean fluid passes through the straining element and continues its flow towards the outlet port of the strainer.

The trapped particles remain within the strainer until it is time for maintenance or cleaning. Many Y strainers are designed with a drain valve or blowdown valve located at the bottom. Opening this valve allows the accumulated debris to be flushed out of the strainer periodically, ensuring its continued efficiency and preventing clogs.

It’s important to note that Y strainers are generally designed for coarse filtration and are not suitable for capturing very fine particles. If finer filtration is required, additional filtration components, such as cartridge filters or bag filters, can be incorporated into the system.

Importance of Y Strainers in Plumbing Systems

Y strainers play a crucial role in plumbing systems and offer several important benefits. Let’s explore the significance of Y strainers in maintaining the efficiency and longevity of plumbing systems.

1. Debris Removal: One of the primary functions of a Y strainer is to remove debris and solid particles from fluid flow. Plumbing systems can be susceptible to the entry of various substances, including dirt, rust, scale, and other contaminants. If left unchecked, these particles can cause blockages, reduce flow rates, and lead to damage to downstream equipment. Y strainers effectively capture and trap these particles, keeping the fluid clean and protecting the system.

2. Equipment Protection: Y strainers act as a protective barrier for valves, pumps, meters, nozzles, and other sensitive equipment in plumbing systems. By preventing the entry of particles and debris, they minimize the risk of clogs, corrosion, and damage to these components. This ultimately extends the lifespan and enhances the performance of the equipment.

3. Maintenance and Cost Savings: Integrating Y strainers into plumbing systems can help reduce maintenance requirements and associated costs. By preventing clogs and keeping the system clean, the need for frequent downtime and repairs is minimized. Additionally, Y strainers help avoid costly equipment replacements by safeguarding against damage caused by debris and particles.

4. Improved Flow Rates: With the removal of debris, Y strainers ensure that fluid flows smoothly through the system. Unclogged pipes and equipment allow for optimal flow rates, reducing the risk of pressure drops and maintaining consistent performance. This is particularly crucial in applications where precise flow control is essential, such as in industrial processes.

5. Versatility and Adaptability: Y strainers can be easily installed in various plumbing systems, including residential, commercial, and industrial setups. They are available in a range of sizes, materials, and mesh options to accommodate different flow rates, fluid types, and specific application requirements. This versatility makes Y strainers a valuable tool for maintaining efficiency across diverse plumbing systems.

Overall, Y strainers are integral components in plumbing systems, providing effective debris removal, equipment protection, cost savings, improved flow rates, and adaptability. By incorporating Y strainers into plumbing design and maintenance practices, system operators can ensure the reliable and efficient operation of their plumbing systems for years to come.

Benefits of Using Y Strainers

Using Y strainers in plumbing systems offers several key benefits that contribute to the overall efficiency and longevity of the system. Let’s explore the advantages of incorporating Y strainers into your plumbing setup.

1. Debris Removal: Y strainers effectively remove solid particles and debris from the fluid flow, preventing them from causing blockages and damage to downstream equipment. By keeping the system clean, Y strainers help maintain optimal flow rates and minimize the risk of downtime and costly repairs.

2. Equipment Protection: Y strainers act as a protective barrier for valves, pumps, meters, and other sensitive equipment in plumbing systems. By trapping particles and preventing them from reaching the equipment, Y strainers help extend the lifespan and improve the performance of these components.

3. Versatility: Y strainers are available in various sizes, materials, and mesh options, allowing them to be used in a wide range of plumbing applications. Whether it’s a residential household or an industrial facility, Y strainers can be tailored to meet the specific requirements of the system.

4. Easy Installation: Y strainers are relatively simple to install and integrate into existing plumbing systems. They can be easily positioned in the pipeline and connected without requiring extensive modifications or downtime. This ease of installation ensures minimal disruption during the implementation process.

5. Low Maintenance: Y strainers require minimal maintenance, primarily involving periodic cleaning or flushing of the trapped debris. Many Y strainers are equipped with drain valves, which make the maintenance process quick and hassle-free. Regular maintenance helps ensure the continued efficiency of the strainer and the overall system.

6. Cost-Effective Solution: By preventing clogs and protecting downstream equipment, Y strainers help reduce the need for frequent repairs and replacements. This translates to cost savings in terms of maintenance, downtime, and replacement of expensive equipment. Investing in Y strainers upfront can lead to long-term cost-effectiveness for plumbing systems.

7. Improved System Performance: With the removal of debris, Y strainers help maintain consistent flow rates and prevent pressure drops in the system. This contributes to the overall performance and efficiency of the plumbing system, ensuring smooth operation and optimal functionality.

Different Types of Y Strainers

Y strainers are available in various types, each designed to cater to specific applications and fluid flow requirements. Understanding the different types can help you choose the most suitable Y strainer for your plumbing needs. Let’s explore some common types of Y strainers:

1. Cast Iron Y Strainers: These Y strainers are made of durable cast iron material, making them ideal for heavy-duty applications and industrial settings. They provide excellent strength and resistance to corrosion, making them suitable for handling a wide range of fluids, including water, oil, and chemicals.

2. Stainless Steel Y Strainers: Y strainers made of stainless steel offer superior corrosion resistance and are well-suited for applications where hygiene and cleanliness are crucial. Stainless steel Y strainers are commonly used in the food and beverage industry, pharmaceuticals, and other sanitary applications.

3. Brass Y Strainers: Brass Y strainers are known for their excellent thermal conductivity and resistance to certain chemicals. They are often used in plumbing systems where water flow needs to be regulated or in applications that require protection against water hammer or thermal expansion.

4. PVC Y Strainers: PVC Y strainers are lightweight and resistant to corrosion, making them suitable for plumbing systems that handle non-aggressive fluids. They are commonly used in residential and commercial applications, such as irrigation systems and water treatment facilities.

5. Flanged Y Strainers: Flanged Y strainers feature flanged connections, making them easy to install and remove from the pipeline. They are often used in applications with higher flow rates and larger pipe sizes, providing efficient debris removal without compromising system performance.

6. Threaded Y Strainers: Threaded Y strainers have threaded connections, allowing for easy installation in smaller pipe sizes. These strainers are commonly used in residential plumbing systems, process piping, and low-flow applications.

7. Large Capacity Y Strainers: Large capacity Y strainers are designed to handle high flow rates and larger pipe sizes. They are often used in industrial sectors, such as power plants, chemical processing plants, and water treatment facilities, where efficient filtration of large volumes of fluid is essential.

It’s important to consider the specific requirements of your plumbing system, such as flow rate, fluid type, pressure, and temperature, when selecting a Y strainer. Consulting with a professional or supplier can help you determine the most suitable type of Y strainer for your specific needs.

Choosing the Right Y Strainer for Your Needs

Choosing the right Y strainer for your plumbing needs is essential to ensure optimal performance and longevity of your system. Consider the following factors when selecting a Y strainer:

1. Flow Rate: Determine the flow rate of your system, which is typically measured in gallons per minute (GPM) or liters per minute (LPM). Select a Y strainer that can handle the anticipated flow rate to prevent pressure drops and maintain efficient fluid flow.

2. Pipe Size: Know the diameter of your pipe to ensure compatibility with the Y strainer. Y strainers are available in various sizes, so choose one that matches or is slightly larger than your pipe diameter for proper installation.

3. Fluid Type: Consider the type of fluid that will be flowing through the strainer. Some fluids may require specific materials for optimal compatibility and performance. For example, corrosive or aggressive fluids may require a stainless steel or PVC Y strainer, while high-temperature applications may require materials with greater heat resistance.

4. Pressure Rating: Determine the maximum operating pressure of your system and choose a Y strainer that can withstand that pressure. Ensure that the strainer is rated at or above the operating pressure to prevent leakage or damage under normal operation.

5. Filtration Requirements: Assess the level of filtration needed for your system. Y strainers typically have different mesh sizes available, which dictate the particle size they can capture. Determine the size of the particles that need to be removed and select a Y strainer with an appropriate mesh size to suit your filtration requirements.

6. Construction Material: Consider the material of the Y strainer based on the fluid characteristics and the environment it will be installed in. Stainless steel, brass, cast iron, and PVC are common materials used for Y strainer construction, each with its own advantages and limitations in terms of strength, corrosion resistance, and compatibility with different fluids.

7. Maintenance and Cleaning: Evaluate the ease of maintenance and cleaning of the Y strainer. Look for features such as drain valves or blowdown valves that facilitate regular flushing of trapped debris. This helps ensure the continued efficiency of the strainer and reduces maintenance requirements.

By considering these factors and consulting with a knowledgeable professional or supplier, you can choose the right Y strainer that meets your specific needs and ensures optimal performance of your plumbing system.

Installation and Maintenance of Y Strainers

The proper installation and regular maintenance of Y strainers are crucial for ensuring their effectiveness and longevity. Follow these guidelines for the installation and ongoing maintenance of Y strainers:

Installation:

- Positioning: Install the Y strainer in the pipeline where it can effectively capture debris and contaminants. Position it in a way that allows for easy access for maintenance and cleaning.

- Orientation: Ensure that the Y strainer is oriented correctly in relation to the fluid flow. Typically, the inlet should be positioned at the bottom and the outlet at the top to facilitate efficient filtration.

- Gaskets and Seals: Use appropriate gaskets and seals to ensure a tight and leak-free installation. This helps prevent fluid bypass and ensures that all flow is directed through the straining element.

- Tightening: Tighten the bolts or nuts evenly to secure the Y strainer in place. Avoid over-tightening, as this can distort the housing or damage the sealing surfaces.

- Connections: Connect the Y strainer to the upstream and downstream piping using appropriate fittings or flanges. Ensure a secure and leak-free connection to maintain system integrity.

Maintenance:

- Regular Inspection: Conduct visual inspections of the Y strainer to check for any signs of damage, corrosion, or excessive buildup. Inspect the straining element for any clogs or damage that may affect its performance.

- Cleaning and Flushing: Periodically flush and clean the Y strainer to remove accumulated debris. Close the inlet and outlet valves, open the drain valve or blowdown valve, and allow the trapped particles to be flushed out. Rinse the strainer and the straining element thoroughly before reassembling.

- Reusable Mesh Cleaning: If using a reusable mesh straining element, thoroughly clean it with an appropriate cleaning solution or solvent to remove any residual buildup. Follow the manufacturer’s instructions for cleaning and maintenance.

- Replacement: If the straining element becomes damaged, worn out, or is no longer effectively filtering particles, replace it promptly. Ensure that the replacement element is of the correct size and mesh specification.

- Record Keeping: Maintain a maintenance log or record of all inspections, cleanings, and replacements performed on the Y strainer. This helps track the history of maintenance and provides valuable information for future maintenance needs.

Adhering to proper installation procedures and performing regular maintenance will ensure that your Y strainer continues to function effectively, protecting your plumbing system from debris and maintaining optimal flow rates.

Common Issues and Troubleshooting with Y Strainers

While Y strainers are reliable and effective components in plumbing systems, they can occasionally experience issues that affect their performance. Understanding common issues and troubleshooting methods can help you address these problems promptly. Here are some common issues and troubleshooting steps for Y strainers:

1. Reduced Flow Rate: If you notice a decrease in the flow rate through the Y strainer, it could indicate a clogged straining element. The solution is to clean or replace the straining element to restore proper flow and filtration.

2. Leaks: Leaks can occur at the connections or seals of the Y strainer. Tighten any loose connections or bolts to ensure a secure and leak-free installation. Replace damaged or worn-out gaskets or seals to prevent leakage.

3. Corrosion and Rust: Over time, Y strainers can develop corrosion and rust, especially in environments with aggressive fluids. Regular inspection and maintenance can help identify early signs of corrosion. Replace any corroded or rusted components promptly to prevent leaks and maintain the integrity of the strainer.

4. Improper Installation: Issues may arise if the Y strainer is not installed correctly. Double-check the orientation and positioning of the Y strainer to ensure that the fluid flows through it properly. Refer to the installation guidelines provided by the manufacturer or consult a professional if needed.

5. Damaged or Worn Strainer Element: A damaged or worn-out strainer element may not effectively capture particles, leading to reduced filtration efficiency. Inspect the strainer element regularly and replace it if it shows signs of damage, such as tears or excessive wear.

6. Clogging and Debris Buildup: Y strainers can become clogged with debris over time. Regular cleaning and flushing of the strainer can help prevent excessive debris buildup. If the straining element is not removable or reusable, consider replacing it with a clean one to maintain filtration efficiency.

7. Inadequate Filtration: If particles are passing through the strainer and affecting downstream equipment, it could indicate that the mesh size of the strainer element is not suitable for the application. Consider selecting a strainer element with a finer mesh size for improved filtration.

8. High Pressure Drops: Excessive pressure drops across the Y strainer can impact system performance. Check for any obstructions in the strainer element or the pipes leading to and from the Y strainer. Clear any blockages and ensure unrestricted flow to minimize pressure drops.

If you encounter any issues with your Y strainer that you are unable to troubleshoot or resolve, seek assistance from a professional plumber or contact the manufacturer for guidance. Prompt identification and resolution of issues with Y strainers will help maintain the effectiveness and efficiency of your plumbing system.