Importance of Cable Wire Tray

A cable wire tray is an essential component in any electrical or data communication system. It plays a crucial role in supporting and organizing cables, providing a safe and efficient solution to manage the network infrastructure. Here are a few reasons why cable wire trays are important:

- Organization and Cable Management: One of the primary benefits of cable wire trays is their ability to neatly organize and manage cables. They prevent cables from getting tangled or scattered, making it easier to identify and trace specific wires when troubleshooting or making changes to the network.

- Protection and Safety: Cable wire trays protect cables from damage caused by external factors such as moisture, dust, and excessive heat. They also prevent accidental contact with cables, reducing the risk of electrical hazards and ensuring the safety of personnel and equipment.

- Easy Maintenance and Accessibility: With cables neatly organized within a cable wire tray, maintenance and repairs become more convenient. Technicians can easily access and identify specific cables, making upgrades or replacements faster and less disruptive to the overall network.

- Flexibility and Scalability: Cable wire trays offer flexibility in cable routing, allowing for easy expansion and modification of the network infrastructure. As your system grows or changes over time, cable wire trays can be easily adjusted or extended to accommodate new cables without the need for extensive rewiring.

- Improved Airflow and Reduced Heat: Cable wire trays promote better airflow around cables, preventing the accumulation of heat and reducing the risk of overheating. This ensures optimal performance and prolongs the lifespan of the cables and other sensitive network equipment.

Overall, cable wire trays help create a well-organized, safe, and efficient network infrastructure. They simplify cable management, protect cables from damage, and provide easy access for maintenance and future growth. By investing in quality cable wire trays, you can enhance the performance and reliability of your electrical or data communication system.

Types of Cable Wire Tray

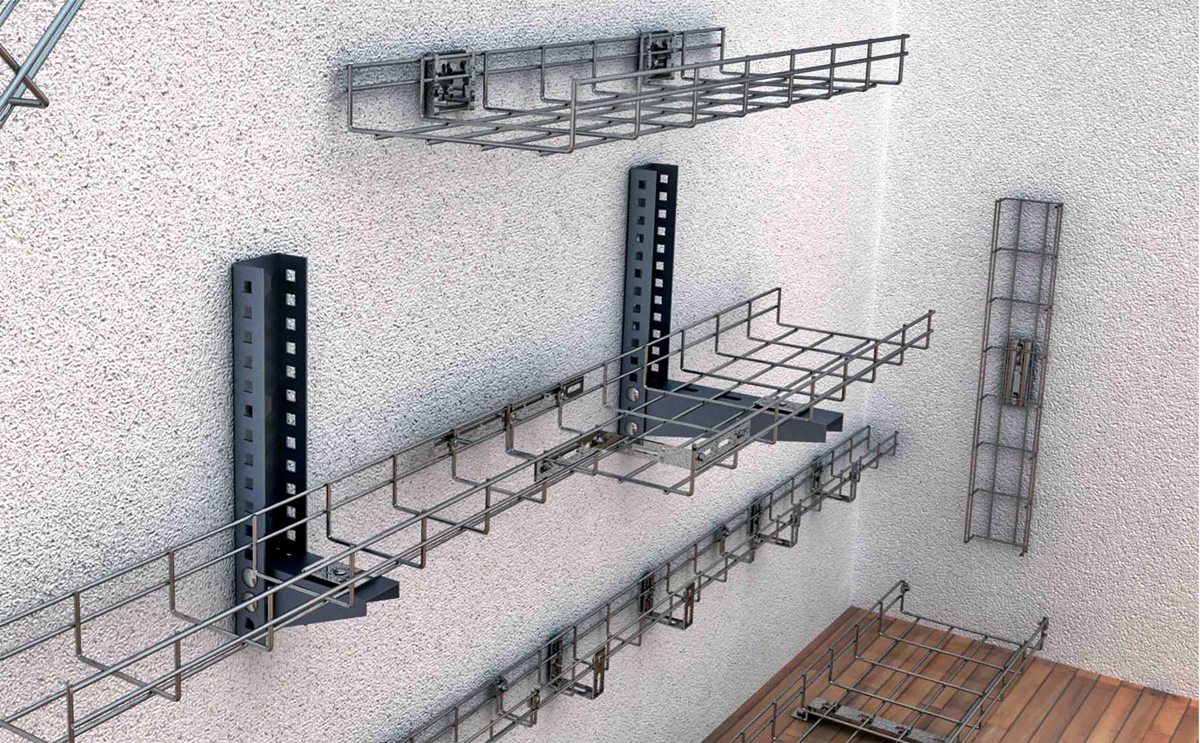

There are several types of cable wire trays available, each designed to suit specific requirements and environments. Here are the most common types:

- Wire Mesh Cable Trays: Wire mesh cable trays are made of welded wires that form a grid pattern. They are lightweight, easy to install, and allow for good airflow. These trays are suitable for low to medium cable volumes and can be used in a variety of environments.

- Ladder Cable Trays: Ladder cable trays are constructed with a series of parallel wires joined by horizontal crossbars. They provide excellent cable support and have a higher load-bearing capacity compared to wire mesh trays. Ladder cable trays are commonly used in industrial applications where heavy-duty cable management is required.

- Solid Bottom Cable Trays: Solid bottom cable trays have a solid base that provides additional support and protection for the cables. They are suitable for environments where there is a risk of small objects falling onto the cables. Solid bottom trays are commonly used in outdoor installations or areas with high levels of dust or debris.

- Trough Cable Trays: Trough cable trays have a semi-enclosed design with sidewalls that provide extra cable protection. They are ideal for applications where cables need additional shielding or where there is a requirement for segregated routing of power and data cables.

- Snake Cable Trays: Snake cable trays have a flexible design that allows for easy installation around obstacles or uneven surfaces. They are suitable for areas where straight cable routing is not possible, such as around corners or in tight spaces where flexibility is required.

Each type of cable wire tray has its own advantages, and the choice depends on factors such as cable volume, load-bearing requirements, environmental conditions, and installation constraints. It is important to assess your specific needs and consult with a professional to determine the most suitable type of cable wire tray for your application.

Advantages of Cable Wire Tray

Cable wire trays offer numerous advantages in terms of cable management, installation, maintenance, and overall system performance. Here are some key advantages of using cable wire trays:

- Efficient Cable Organization: Cable wire trays provide a systematic and organized approach to cable management. They keep cables neatly arranged, eliminating the risk of tangles or confusion during maintenance or troubleshooting.

- Easy Access and Maintenance: With cables securely placed in wire trays, technicians can easily access and identify specific cables when needed. This makes the maintenance and repair process quicker and more efficient, minimizing downtime and disruptions to the network.

- Flexibility and Scalability: Cable wire trays are designed to accommodate changing needs and system expansions. They allow for easy additions or modifications to the cable routing, enabling seamless integration of new cables or reconfigurations in the future.

- Enhanced Airflow and Cooling: Proper cable management with wire trays promotes better airflow around the cables, preventing heat buildup. This helps maintain optimal operating temperatures for sensitive network equipment, improving overall performance and extending their lifespan.

- Cost-Effective Solution: Cable wire trays offer a cost-effective alternative to traditional conduit systems. They require less material, labor, and time for installation, resulting in reduced overall project costs.

- Improved Safety: Cable wire trays provide a secure housing for cables, preventing accidental contact and electrical hazards. They also comply with safety regulations, ensuring the well-being of personnel and protecting equipment from potential damage.

- Durability and Longevity: High-quality cable wire trays are built to withstand the rigors of demanding environments. They are made of durable materials that resist corrosion, impact, and other forms of damage, ensuring a long lifespan and reliable cable management.

- Versatility: Cable wire trays are versatile and can be used in a wide range of applications, including commercial buildings, industrial facilities, data centers, and more. They can accommodate different cable types and sizes, making them a flexible solution for various network setups.

Overall, cable wire trays offer numerous advantages in terms of organization, accessibility, flexibility, cooling, cost, safety, durability, and versatility. By investing in cable wire trays, you can optimize your cable management system and enhance the performance and longevity of your network infrastructure.

Installation Process of Cable Wire Tray

The installation of cable wire trays involves several key steps to ensure a secure and efficient cable management system. Here is a general guide to the installation process:

- Planning and Design: Start by assessing your cable management needs and mapping out the desired cable routing paths. Consider factors such as cable length, load-bearing requirements, accessibility, and any specific installation constraints.

- Preparation: Gather all the necessary tools and materials for installation, including cable wire trays, brackets, fasteners, and appropriate safety equipment. Measure and mark the mounting locations on the walls or ceilings where the wire trays will be installed.

- Mounting Brackets: Install the mounting brackets or supports onto the walls or ceilings, ensuring they are securely fastened. Use a level to ensure the brackets are aligned correctly for horizontal or vertical installations.

- Connecting Wire Trays: Connect the cable wire trays together using connectors or couplers based on the desired cable routing. Ensure that the connections are tight and secure to prevent any movement or sagging of the trays.

- Fixing Cable Trays: Attach the cable wire trays to the mounting brackets using appropriate fasteners such as screws or bolts. Ensure that the trays are level and properly aligned with the marked locations to maintain a neat and organized appearance.

- Cable Installation: Lay the cables inside the wire trays, making sure to follow the planned routing paths. Secure the cables to the trays using cable ties or Velcro straps to prevent any movement or strain on the cables.

- Grounding: Install grounding components at appropriate intervals as per electrical safety regulations. This helps to dissipate any potential voltage differences and ensures the safety of the system and personnel.

- Testing and Inspection: Once the installation is complete, conduct thorough testing and inspection to ensure proper functionality and adherence to safety standards. Check for proper cable organization, secure tray connections, and adequate grounding.

It is important to follow installation guidelines provided by manufacturers and consult with professionals if needed, especially for complex or large-scale installations. Proper installation of cable wire trays is crucial to ensure a secure and reliable cable management system that meets your specific requirements.

Maintenance of Cable Wire Tray

Regular maintenance of cable wire trays is essential to ensure their longevity, optimal performance, and the safety of the network infrastructure. Here are some key maintenance practices to follow:

- Inspection: Regularly inspect the cable wire trays for any signs of damage, wear, or corrosion. Look for loose connections, bent wires, or damaged coatings that may affect the structural integrity of the trays.

- Cable Routing: Check the cable routing within the trays to ensure that cables are properly organized and secured. Adjust any loose cables or cable ties to avoid strain or tangling, which can lead to cable damage or performance issues.

- Cleanliness: Keep the cable wire trays clean and free from dust, debris, or any other materials that may obstruct cable pathways. Regularly remove any accumulation of dirt or foreign objects to maintain optimal airflow and prevent potential cable damage.

- Corrosion Protection: If the cable wire trays are installed in areas prone to corrosion, such as outdoor or high moisture environments, consider applying corrosion-resistant coatings or treatments to protect the trays from damage.

- Proper Load Distribution: Ensure that heavy cables or equipment are evenly distributed within the cable wire trays. Avoid overloading any specific sections, as this can lead to tray deformation or structural issues.

- Regular Testing: Periodically test the grounding and electrical continuity of the cable wire trays to ensure their effectiveness in preventing electrical hazards. Conduct insulation resistance tests to identify any potential cable insulation failures.

- Professional Inspections: Schedule periodic inspections by qualified professionals to assess the overall condition and performance of the cable wire trays. They can identify any underlying issues or potential risks that may require attention or maintenance.

- Documentation and Record-Keeping: Maintain a detailed record of maintenance activities, inspections, and any repairs or replacements performed on the cable wire trays. This documentation can help track the history of the trays and assist in future maintenance planning.

By implementing these maintenance practices, you can ensure that your cable wire trays remain in good condition, allowing for efficient cable management and a reliable network infrastructure. Regular inspections and proactive maintenance help identify and address any issues before they escalate, ensuring the longevity and optimal performance of the cable wire tray system.

Choosing the Right Cable Wire Tray for Your Needs

Choosing the right cable wire tray is essential to ensure effective cable management and meet the specific requirements of your application. Here are some factors to consider when selecting a cable wire tray:

- Cable Capacity: Determine the maximum number and size of cables that the wire tray needs to accommodate. Consider the current and future cable requirements to ensure sufficient capacity for expansion.

- Load-Bearing Requirements: Assess the weight of the cables and any additional equipment that will be supported by the wire tray. Choose a tray with the appropriate load-bearing capacity to ensure structural integrity and prevent sagging.

- Environmental Considerations: Consider the environmental conditions where the cable wire tray will be installed. Factors such as moisture, temperature fluctuations, chemical exposure, or outdoor elements should be taken into account to select trays with appropriate coatings or materials.

- Installation Flexibility: Evaluate the installation requirements and constraints of your project. Some wire tray types, like ladder or solid bottom trays, may be more suitable for specific mounting options or configurations compared to others. Choose a tray that aligns with your installation needs.

- Access and Maintenance: Consider the ease of access for future maintenance or cable additions/removals. Select a wire tray that allows for simple and convenient cable routing and provides ample space for any necessary maintenance procedures.

- Compliance with Codes and Standards: Ensure that the cable wire tray you choose complies with relevant industry codes and standards. This includes considerations for safety, electrical grounding, fire resistance, and other regulatory requirements.

- Budget and Long-Term ROI: Evaluate the cost-effectiveness and long-term return on investment (ROI) of the wire tray. While it is important to stay within your project budget, also consider the durability, maintenance requirements, and expected lifespan of the tray to make an informed decision.

It is recommended to consult with experienced professionals or suppliers who specialize in cable management systems. They can provide valuable insights and recommendations based on your specific needs and project requirements. Taking the time to select the right cable wire tray will help ensure a well-organized, efficient, and future-proof cable management solution that meets your current and future needs.

Common Challenges with Cable Wire Tray

While cable wire trays offer numerous benefits, there are also some common challenges that can arise during their installation or use. Being aware of these challenges will help you address them appropriately. Here are some common challenges associated with cable wire trays:

- Cable Overloading: One challenge is the tendency to overload cable wire trays, exceeding their load-bearing capacity. This can cause sagging or even structural failure, leading to potential damage to the cables or the tray system itself. It is important to carefully consider the weight and quantity of cables to prevent overloading.

- Cable Congestion: Insufficient planning and organization of cables within the wire tray can result in cable congestion and limited space for future expansions or maintenance. It is crucial to properly route and manage cables within the tray to maintain an efficient and accessible cable management system.

- Interference and Crosstalk: If different types of cables, such as power and data cables, are not adequately separated within the cable wire tray, interference and crosstalk can occur. This can lead to signal degradation or electrical noise, impacting the overall performance and reliability of the system.

- Poor Cable Protection: If cable wire trays are not adequately designed or installed, cables may be exposed to potential damage from external factors such as moisture, excessive heat, or mechanical stress. Care should be taken to ensure proper cable protection to maintain the integrity and longevity of the cables.

- Inadequate Grounding: Proper grounding is essential for the safety and performance of the cable wire tray system. Inadequate grounding can result in electrical hazards or improper functioning of equipment. It is important to follow electrical safety regulations and ensure proper grounding practices during installation.

- Lack of Proper Maintenance: Neglecting regular maintenance can lead to issues such as loose connections, cable strain, or accumulation of debris within the wire tray. Regular inspections and cleaning are necessary to address these maintenance needs and ensure the continued functionality and safety of the cable wire tray system.

- Compatibility Issues: When integrating different components or accessories with cable wire trays, compatibility issues may arise. It is important to verify that accessories such as bends, tees, or connectors are compatible with the specific wire tray type and dimensions to ensure a proper fit and functionality.

By being aware of these common challenges, proper planning, installation, and maintenance measures can be put in place to mitigate or address them effectively. Consultation with professionals and adherence to industry standards will help overcome these challenges and ensure a successful cable wire tray implementation.

Safety Regulations for Cable Wire Tray Installation

When installing cable wire trays, it is crucial to prioritize safety to protect personnel and ensure compliance with relevant regulations. Here are some important safety regulations to consider during cable wire tray installation:

- Electrical Codes and Standards: Familiarize yourself with local electrical codes and standards that govern cable wire tray installation. These codes prescribe guidelines for grounding, cable separation, fire resistance, and other safety considerations. Compliance with these regulations is crucial to ensure a safe installation.

- Proper Grounding: Adequate grounding is essential to prevent electrical hazards and minimize electrical noise. Follow grounding requirements specified by electrical codes, including properly connecting grounding conductors to the cable wire trays and associated equipment. Check the resistance of the grounding system to ensure it falls within acceptable limits.

- Cable Separation: Maintain proper separation between different types of cables within the wire tray to prevent interference and crosstalk. Follow regulations that specify minimum separation distances, especially between power and data communication cables, to ensure optimal performance and reduce the risk of electrical interference.

- Fire Resistance: Ensure that the cable wire tray system meets the required fire resistance standards. This may involve choosing fire-rated materials or using firestop devices to maintain the integrity of fire-rated walls or floors where cable penetrations are made. Adhere to regulations to mitigate fire risks and protect personnel and equipment.

- Load Capacity: Never exceed the load capacity specified by the manufacturer for the cable wire trays. Overloading the trays can lead to structural failure, posing risks to personnel and equipment. Carefully calculate the weight of the cables and any additional loads to ensure the trays can safely support them.

- Safe Installation Practices: Follow safe practices during installation, such as using appropriate personal protective equipment (PPE) and ensuring secure mounting of the wire trays. Fasteners should be properly tightened, and trays should be properly aligned to prevent accidents or tray detachment after installation.

- Training and Qualifications: Ensure that personnel involved in the cable wire tray installation are appropriately trained and qualified. They should have a good understanding of safety regulations, installation techniques, and the use of necessary tools and equipment. Regularly provide training updates to stay updated with the latest safety practices.

It is essential to consult with qualified professionals and local authorities to ensure compliance with safety regulations specific to your region. By adhering to these safety regulations, you can create a safe working environment, minimize the risk of accidents, and ensure the proper functioning and longevity of your cable wire tray system.

Differences between Cable Wire Tray and Conduit

When it comes to cable management solutions, cable wire trays and conduits are two common options available. While both serve the purpose of protecting and organizing cables, there are several key differences between the two. Here are some of the main distinctions:

- Design: Cable wire trays have an open structural design, typically consisting of wire mesh or ladder-style configurations. Conduits, on the other hand, are enclosed tubes or pipes that provide a closed pathway for cables.

- Accessibility: Cable wire trays provide easy access to cables, allowing for simple cable routing and maintenance. Conduits, being enclosed, require more effort and time to access and modify cables within the system.

- Flexibility: Cable wire trays offer more flexibility in cable routing. They accommodate cables of various sizes and types, allowing for easy modifications and additions. Conduits, once installed, provide limited flexibility for cable changes and may require significant rework.

- Load Capacity: Cable wire trays are designed to support varying loads of cables, depending on their type and design. Conduits have a fixed load capacity based on their size and material, and exceeding this capacity can result in damage or collapse.

- Cable Management: Cable wire trays excel in managing large bundles or volumes of cables. They allow for proper airflow around cables, reducing the risk of heat buildup. Conduits, being enclosed, may limit airflow and can potentially lead to heat-related issues.

- Cost: Cable wire trays generally have a lower upfront cost compared to conduit systems. They require less material and labor for installation. Conduits, being enclosed and needing a more complex installation process, tend to be more expensive.

- Flexibility in Installation: Cable wire trays can be mounted on walls, ceilings, or floors using various supports and brackets. Conduits, on the other hand, are typically embedded in walls, hidden from view in a fixed position.

Both cable wire trays and conduits have their advantages and are suited for different applications. Cable wire trays are generally preferred in situations where flexibility, accessibility, and easy cable management are required. Conduits are commonly used when a higher level of protection and a more permanent installation method are necessary.

It is important to consider factors such as cable volume, environment, future expansion needs, and budget when deciding between cable wire trays and conduits. Consulting with professionals can help you make an informed decision on which solution best suits your specific cable management requirements.

Applications of Cable Wire Tray

Cable wire trays find application in a wide range of industries and environments where efficient cable management is essential. Here are some common applications of cable wire trays:

- Commercial Buildings: Cable wire trays are widely used in commercial buildings for data communication and electrical systems. They help organize and support cables in office spaces, retail stores, schools, hospitals, and other commercial settings.

- Industrial Facilities: Industries such as manufacturing plants, warehouses, and power plants require robust cable management solutions. Cable wire trays provide effective cable routing and protection in these demanding environments, supporting heavy-duty cables and withstanding high temperatures or exposure to chemicals.

- Data Centers: Data centers house a large amount of network cabling and require efficient cable management to ensure optimal performance and easy maintenance. Cable wire trays help maintain proper airflow and accessibility for cable management in data center environments.

- Transportation Infrastructure: Cable wire trays are widely used in transportation infrastructure such as airports, train stations, and subway systems. They assist in organizing and protecting cables for information display systems, communication networks, and security systems.

- Oil and Gas Industry: The oil and gas industry often involves harsh and hazardous environments. Cable wire trays are suitable for these conditions, providing cable management solutions for offshore platforms, refineries, and petrochemical plants.

- Telecommunication: Cable wire trays play a vital role in the telecommunication industry, supporting the extensive network infrastructure required for internet, phone, and television services.

- Renewable Energy: With the growth of renewable energy sources, such as solar and wind power, cable wire trays are utilized for efficient cable management in power generation and distribution systems.

- Infrastructure Projects: Cable wire trays are commonly used in infrastructure projects like tunnels, bridges, and stadiums. They provide organized cable routing for power, lighting, communication systems, and security applications.

The versatility and adaptability of cable wire trays make them suitable for a wide range of applications. Regardless of the industry or environment, cable wire trays provide effective cable management, promoting organization, accessibility, and efficient maintenance of the network infrastructure.