What is Vase Mode?

Vase Mode is a unique printing feature available in Cura, a popular slicing software for 3D printing. Also known as Spiralize Outer Contour, Vase Mode allows you to create hollow objects with a single continuous wall, resembling the shape of a vase or a tube.

Unlike traditional 3D printing, which builds objects layer by layer, Vase Mode prints objects in a seamless helical pattern. This means that there are no individual layers visible, resulting in a smooth and continuous surface. The printer extrudes the filament in a continuous motion, eliminating the need for solid infill or top layers.

Vase Mode is ideal for creating decorative objects, such as vases, candle holders, or artistic sculptures. It is also commonly used for rapid prototyping of models with complex shapes, reducing print time and material usage compared to traditional printing methods.

This printing technique is best suited for objects that do not require structural integrity or high levels of detail. Since there is only one continuous wall, the strength of the printed object is reduced compared to solid prints. However, the lightweight and aesthetically appealing nature of Vase Mode prints outweigh this limitation in many cases.

Moreover, Vase Mode opens up new creative possibilities by allowing you to experiment with different layer heights and print speeds. It enables you to achieve striking visual effects by varying the transparency and thickness of the walls.

Overall, Vase Mode is a valuable tool in the 3D printing world that offers a different approach to creating hollow objects. Its ease of use, speed, and unique aesthetic appeal make it a popular choice among both beginners and experienced users.

Why Use Vase Mode in Cura?

Vase Mode in Cura offers several advantages that make it a preferred choice for certain types of 3D prints:

1. Faster Printing Speed: Since Vase Mode doesn’t require layer-by-layer printing, it can significantly reduce print times compared to traditional methods. The continuous helical pattern allows the printer to move smoothly and quickly, resulting in faster production of hollow objects.

2. Material Efficiency: With Vase Mode, there is no need for infill or top layers, which means less material usage. This can lead to cost savings, especially when printing large objects or multiple prototypes.

3. Seamless and Aesthetic Appeal: Vase Mode produces objects with a continuous single wall, creating a sleek and seamless surface. This unique aesthetic quality makes it perfect for producing decorative items like vases, planters, and sculptures. The absence of visible layers adds a touch of sophistication to the final product.

4. Versatility in Design: Vase Mode enables you to experiment with different wall thicknesses, layer heights, and print speeds. This flexibility allows you to create customized designs with varying levels of transparency and wall strength. You can achieve stunning visual effects by playing around with these parameters.

5. Easy Post-Processing: Since Vase Mode prints typically have a single continuous wall, post-processing is relatively straightforward. Removing support structures, if any, is typically the only necessary step. This saves time and effort compared to cleaning up intricate details and multiple layers found in traditional prints.

6. Rapid Prototyping: Vase Mode is an excellent choice for quickly prototyping models with complex shapes. It allows designers and engineers to visualize their ideas in a shorter time frame, making it easier to iterate and refine designs before moving on to more detailed and structurally robust prints.

7. Educational and Recreational Use: Vase Mode can also be a valuable learning tool for students and hobbyists interested in understanding the principles of 3D printing. Its simplicity and ease of use make it accessible to beginners who want to explore the possibilities of 3D printing without diving into advanced techniques.

Considering these benefits, Vase Mode in Cura is a versatile feature that offers speed, material efficiency, and aesthetic appeal. Whether you’re creating decorative pieces for your home, prototypes for testing, or simply exploring the capabilities of 3D printing, Vase Mode can be an excellent addition to your printing toolbox.

Setting Up Your Print Bed

Before using Vase Mode in Cura, it’s crucial to ensure that your print bed is properly set up. Here are some essential steps to follow:

- Level your bed: Start by ensuring that your print bed is level. Use a leveling tool or follow the manufacturer’s instructions to make sure the bed is flat and even. This is crucial for achieving accurate prints.

- Apply bed adhesion: To prevent your print from shifting or warping during the printing process, it’s essential to apply a suitable bed adhesion material. Depending on your printer and filament, this could be painter’s tape, a glue stick, or a specialized bed adhesive such as a PEI sheet.

- Check filament compatibility: Confirm that the filament you plan to use is compatible with Vase Mode. Some filaments, such as flexible materials or those with higher melting points, may not work well in this mode. Refer to the manufacturer’s guidelines or perform some test prints to ensure successful results.

- Adjust printing temperature: Vase Mode may require different printing temperatures compared to traditional printing. Consult the filament manufacturer’s recommendations and adjust the temperature settings accordingly in your 3D printer software.

- Calibrate your extruder steps/mm: Properly calibrating your extruder ensures that the correct amount of filament is extruded during printing. This calibration ensures accurate wall thickness and overall print quality. Follow your printer manufacturer’s instructions or refer to online resources for a step-by-step guide on calibrating your extruder steps/mm.

- Preheat your printer: Allow your printer to preheat to the desired temperature to ensure consistent filament flow and adhesion to the print bed. Check the recommended preheating temperature for your specific filament and adjust accordingly if needed.

By following these steps, you’ll be able to set up your print bed for Vase Mode in Cura and optimize the printing process. Taking the time to properly prepare your printer and bed can greatly increase the chances of successful prints and minimize any potential issues that may arise.

Selecting Vase Mode in Cura

Once your print bed is properly set up, the next step is to select Vase Mode in Cura. Follow these steps to enable Vase Mode for your print:

- Open Cura: Launch the Cura software on your computer.

- Import or design your model: Import the 3D model you want to print, or use the built-in design tools in Cura to create your own model. Ensure that the model is suitable for Vase Mode printing, with a single continuous wall design.

- Select your printer: Choose the appropriate printer from the list of available printers in Cura. Make sure it matches the printer you are using.

- Set print settings: Adjust the desired settings for your print, such as layer height, print speed, and infill density. Note that some settings, such as infill, are not applicable when using Vase Mode.

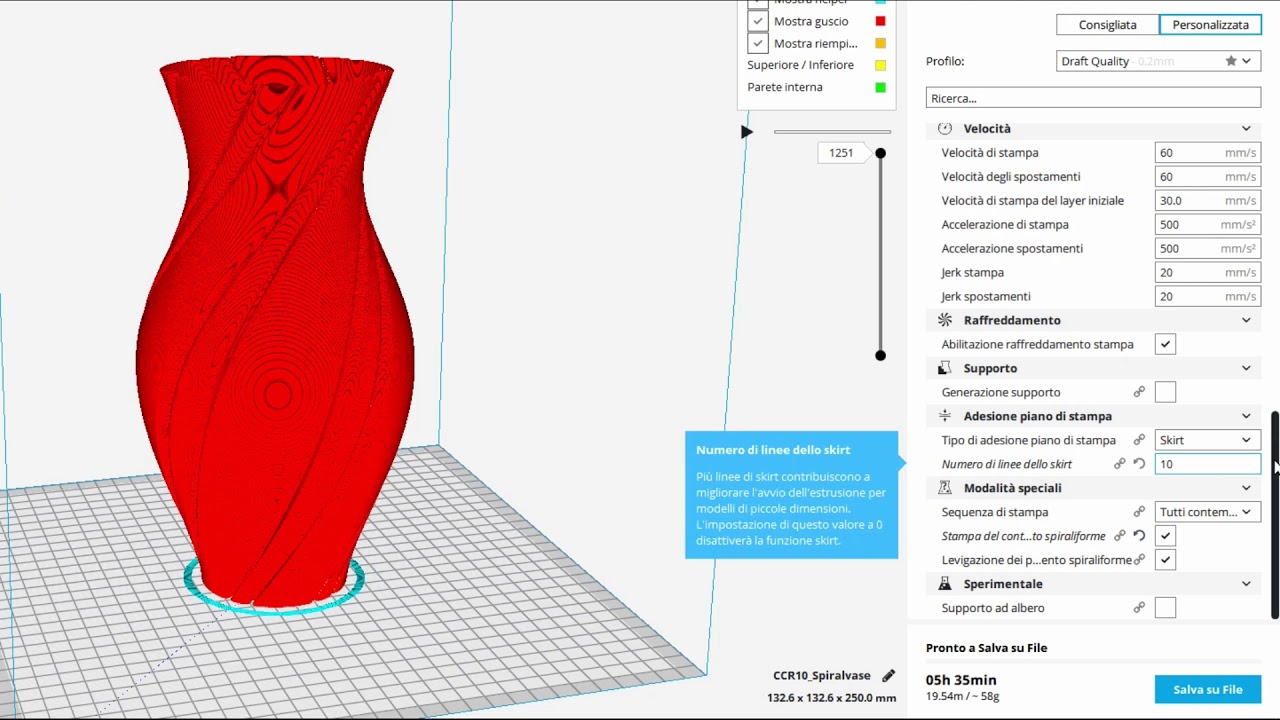

- Enable Vase Mode: Under the “Special Modes” or “Experimental” section of the Cura interface, look for an option called “Spiralize Outer Contour” or “Vase Mode.” Check the box or toggle to enable this feature.

- Review settings: Double-check all the settings to ensure they are appropriate for your print. Pay attention to the layer height and wall thickness settings, as these will directly impact the final result.

- Generate G-code: Once you are satisfied with the settings, click the “Slice” button in Cura to generate the G-code file necessary for your printer to execute the print.

- Save and transfer to printer: Save the G-code file to your computer and transfer it to your 3D printer via USB, SD card, or any other method supported by your printer.

- Start printing: Load the filament, ensure the bed adhesion is in place, and initiate the print on your 3D printer, following the manufacturer’s instructions. Your printer will now execute the Vase Mode print based on the settings you have specified.

By following these steps, you can easily enable Vase Mode in Cura and prepare your model for printing in a continuous spiral pattern. Take your time to review the settings and ensure they align with your desired outcome for the print.

Adjusting Settings for Vase Mode

When using Vase Mode in Cura, it’s important to make certain adjustments to optimize your print. Here are some key settings to consider:

- Layer Height: The layer height determines the thickness of each printed layer. For Vase Mode, a lower layer height will result in a smoother and more detailed print. However, keep in mind that a lower layer height will also increase the overall print time.

- Wall Thickness: The wall thickness setting determines how thick the walls of your print will be. Depending on your specific object and desired aesthetic, you may want to adjust this setting. Thicker walls will result in a stronger print, but too much thickness may cause the print to be overly heavy or take longer to complete.

- Print Speed: In Vase Mode, the continuous spiral motion allows for faster print speeds compared to traditional layer-by-layer printing. However, balance the speed with quality, as too high of a print speed may result in imperfections or distortions on the print surface.

- Top Layers and Infill: In Vase Mode, traditional top layers and infill are not necessary since the object is printed with a single continuous wall. Therefore, these settings can be set to 0 or disabled to save time and materials.

- Retraction: Retraction helps prevent stringing or oozing of filament during travel moves. Adjust the retraction settings based on your specific filament and printer to avoid any undesirable artifacts on the surface of the print.

- Temperature: The optimal printing temperature depends on the type of filament being used. Refer to the manufacturer’s recommendations and adjust the temperature settings accordingly. Bear in mind that Vase Mode prints may require slightly different temperature settings compared to traditional prints.

- Support Settings: Determine if your print requires any support structures. Since Vase Mode prints usually have smooth surfaces with no overhangs, support material may not be necessary. However, for certain complex designs or specific objects, supports may be required.

Remember that these settings may vary depending on your specific printer, filament, and desired outcome. It’s important to experiment and find the optimal settings for your particular Vase Mode prints. Taking the time to fine-tune these adjustments will help you achieve the best possible results.

Determining Wall Thickness

When printing in Vase Mode, determining the appropriate wall thickness for your model is crucial. The wall thickness affects the overall strength, weight, and visual appearance of the printed object. Here are some factors to consider when determining the ideal wall thickness:

- Object Functionality: The intended purpose of the printed object should guide your decision on wall thickness. If the object needs to be structurally sound and withstand certain forces or stresses, a thicker wall may be necessary. On the other hand, if the object is purely decorative and lightweight, a thinner wall can be sufficient.

- Print Time and Material Usage: Thicker walls require more filament and may result in longer print times. Consider the balance between strength and efficiency when deciding on the wall thickness. If print time and material usage are a concern, opting for a thinner wall can help save resources.

- Layer Height and Nozzle Size: The layer height and nozzle size used for the Vase Mode print also impact the wall thickness. A smaller nozzle or a lower layer height can achieve finer details and allow for thinner walls. However, using a larger nozzle or higher layer height will result in thicker walls.

- Visual Appearance: The desired aesthetic of the printed object plays a role in determining the wall thickness as well. Thicker walls can give a more substantial and robust look, while thinner walls can create a delicate and transparent appearance. Consider the design and purpose of the object when deciding on the desired visual appeal.

- Printability: Ensure that the chosen wall thickness is achievable with your specific printer and filament. Some printers may have limitations on the minimum wall thickness they can effectively print. Consult your printer’s specifications and perform test prints to identify the optimal range for wall thickness.

- Testing and Iteration: It’s advisable to print a test model with different wall thicknesses to evaluate the results and make adjustments if necessary. This iterative process allows you to fine-tune the wall thickness until you achieve the desired outcome.

Ultimately, the ideal wall thickness will depend on a combination of functional, aesthetic, and technical factors. Experimenting with different wall thicknesses will help you find the right balance between strength, visual appeal, and printing efficiency for your Vase Mode prints.

Choosing the Right Printer

When it comes to successfully printing in Vase Mode, selecting the right 3D printer is essential. Here are some factors to consider when choosing a printer for Vase Mode printing:

- Print Bed Size: Assess the maximum build volume of the printer to ensure it can accommodate the size of the objects you plan on printing in Vase Mode. Consider the height and diameter of the desired prints when evaluating the print bed size.

- Resolution and Precision: Look for a printer that offers high print resolution and precision. The ability to produce fine details is especially important when working with Vase Mode, as smooth and seamless surfaces are key to achieving the desired aesthetic appeal.

- Extruder and Hotend: The extruder and hotend play a vital role in the quality of Vase Mode prints. Opt for a printer with a reliable extruder system that provides consistent filament flow. A durable and well-designed hotend will help maintain accurate temperature control during longer print jobs.

- Print Speed: Since Vase Mode relies on continuous printing without the need for layer changes, print speed becomes a significant factor. Look for a printer that can handle higher print speeds without compromising print quality and precision.

- Flexibility and Filament Compatibility: Consider the types of filaments that the printer supports. While PLA is commonly used in Vase Mode printing, having the flexibility to experiment with other materials like PETG or TPU can offer varied results and expand creative possibilities.

- Reliability and Support: Research the reputation of the printer manufacturer and reviews from other users. A reliable printer with good customer support can save you from potential frustration and ensure a smooth printing experience.

- Software Compatibility: Check if the printer is compatible with popular slicing software like Cura, which offers Vase Mode as a feature. Ensure that the printer’s firmware allows for easy customization and adjustment of settings specific to Vase Mode.

- Price and Budget: Consider your budget when selecting a printer. Determine the features and capabilities that are most important to you and find a printer that offers them within your price range.

- Community and Resources: A strong community and online resources dedicated to the printer model can be invaluable for troubleshooting, finding tips, and discovering new techniques to improve your Vase Mode prints.

By carefully considering these factors, you can choose a printer that meets your specific needs for Vase Mode printing. Remember to prioritize the features that are most important to you and find a balance between affordability and performance.

Printing a Vase in Vase Mode

Once you have set up your printer and prepared the model in Cura with Vase Mode enabled, you are ready to start printing a vase in Vase Mode. Follow these steps to ensure a successful print:

- Prepare the Print Bed: Clean the print bed and ensure that the bed adhesion material is applied according to the recommendations for your specific filament. This will help ensure proper adhesion and prevent any shifting during the print.

- Load and Prime the Filament: Load the filament into the printer’s extruder and prime it to ensure a smooth flow of filament during the print. Follow the manufacturer’s instructions for loading and priming the filament.

- Initiate the Print: Transfer the sliced G-code file to your printer and start the print process. Check that the printer is properly preheated to the recommended temperature for your filament.

- Monitor the Print: Keep an eye on the initial layers to verify that the filament is properly sticking to the bed. Make sure the print is coming out correctly, without any issues like underextrusion or layer shifting. Address any problems that may arise promptly.

- Avoid Interruptions: Once the print is in progress, try to minimize any interruptions that could negatively impact the print quality. Avoid inadvertently bumping the printer or causing vibrations around it, as this can affect the stability of the vase being printed.

- Observe Progress and Make Adjustments: Regularly monitor the progress of the print to ensure everything is going smoothly. If necessary, make adjustments to the printer settings during the print, such as filament temperature or print speed, to optimize the output quality.

- Post-Processing: Once the print is complete, allow it to cool completely on the print bed before removing it. Carefully detach the printed vase from the print bed or remove any necessary support structures. Use caution to avoid damaging the delicate features of the print during this process.

- Clean and Finish: Clean up any excess material or support remnants from the printed vase. Use sandpaper or finishing tools as needed to smooth the surface or refine any imperfections. Consider applying a protective coating or paint to enhance the appearance of the print, if desired.

- Showcase and Enjoy: Display your beautifully printed vase proudly. Use it as a centerpiece, a decorative item, or a gift for someone special.

Printing a vase in Vase Mode can be a rewarding experience. By following these steps and adopting good printing practices, you can achieve high-quality prints with a seamless, continuous appearance.

Troubleshooting Vase Mode Prints

While Vase Mode printing can yield stunning results, it’s not uncommon to encounter occasional issues that may affect the quality of your prints. Here are some common problems and troubleshooting steps to help you overcome them:

- Poor or Inconsistent Wall Thickness: If you notice variations or inconsistent wall thickness in your prints, check the nozzle for partial clogs or filament inconsistencies. Ensure that the filament is flowing smoothly and that the extruder is calibrated correctly to ensure consistent extrusion.

- Stringing or Oozing: Stringing or oozing of filament can be a common issue in Vase Mode prints. Reduce the print temperature to minimize the viscosity of the filament. Adjust retraction settings to prevent filament drooling between movements, and consider using a higher travel speed to minimize the chance of filament oozing.

- Layer Shifts: Layer shifts occur when the print shifts position during the printing process. This issue can be caused by loose belts, improper tension, or mechanical issues. Check that all belts and pulleys are properly tightened and that the printer’s mechanical components are well-maintained and functioning correctly.

- Adhesion Problems: If the print is not adhering properly to the print bed, ensure that the bed is clean and properly leveled. Adjust the first layer height and print bed temperature as needed to improve adhesion. Applying a suitable bed adhesion material, such as painter’s tape or a specialized bed adhesive, can also help improve adhesion.

- Uneven Surface or Visible Layer Lines: If you notice an uneven surface or visible layer lines on your Vase Mode prints, consider adjusting the layer height and print speed settings. Finer layer heights and slower print speeds can help achieve a smoother surface finish. Additionally, check that the printer’s X and Y axes are properly calibrated to ensure accurate movement.

- Filament Quality Issues: In some cases, the quality of the filament itself can affect the print. Ensure that the filament is stored in a dry environment and free from moisture. Consider using high-quality filament from reputable manufacturers to minimize filament-related issues.

- Overhangs and Bridging: Although Vase Mode printing doesn’t typically involve overhangs or bridging, certain designs may still require support structures for successful printing. Determine if your object requires support and add it accordingly in areas where the filament may droop or sag during the print.

- Software and Slicer Settings: Check that you are using the latest version of your slicing software, as software updates can address known issues and improve print quality. Verify that all settings in the slicing software, such as wall thickness, infill, and print speed, are appropriate for Vase Mode printing.

When troubleshooting issues with Vase Mode prints, it’s essential to approach the problem systematically, ruling out potential causes one by one. Keep a log of the changes you make to settings and observe their impact on your prints.

By identifying and addressing these common issues, you can overcome challenges and achieve high-quality Vase Mode prints with consistent results.

Removing and Finishing the Print

Once your Vase Mode print is complete, the final step is to carefully remove and finish the print to achieve the desired result. Here’s how to do it:

- Allow the Print to Cool: Allow the printed object to cool completely on the print bed before attempting to remove it. This ensures that the print has solidified and reduces the risk of deformation or damage.

- Remove from the Print Bed: Gently detach the print from the print bed. If needed, use a spatula or putty knife to carefully pry the print off the bed. Exercise caution to prevent any abrupt or forceful movements that could damage the print or the printer.

- Clean Up Support Structures: If support structures were used during the print, carefully remove them using tools appropriate for the material. Take care not to leave any remnants that may affect the appearance or functionality of the print.

- Sand and Smooth the Surface: Use sandpaper or sanding tools to smooth any rough edges, imperfections, or visible layer lines on the print. Start with a rough grit and gradually progress to a finer grit to achieve a polished and refined finish. Take your time and be gentle to avoid damaging delicate features.

- Post-Process for Desired Finish: Depending on the desired finish, you may want to apply additional post-processing techniques. This can include priming, painting, or coating the print with a clear finish to enhance its appearance and protect it from external elements. Follow the appropriate techniques and materials for the specific filament and desired results.

- Inspect for Quality: Carefully inspect the print for any remaining defects or areas that may require additional touch-ups or refinements. Address any imperfections as needed, ensuring a high-quality and visually appealing final result.

- Display and Enjoy: Once the print has been cleaned, smoothed, and finished to your satisfaction, proudly showcase your Vase Mode masterpiece. Whether it’s a decorative piece, a functional item, or a gift, enjoy the fruits of your 3D printing labor.

Remember to work patiently and methodically when removing and finishing your Vase Mode prints. Taking the time to properly care for and enhance the final product will result in a more professional and impressive outcome.