What is a Diode?

A diode is a fundamental electronic component that plays a vital role in controlling the flow of electrical current in a circuit. It is a two-terminal device, typically made of a semiconductor material, that allows current to flow in one direction while blocking it in the opposite direction.

The primary function of a diode is to enforce the flow of current in a specific direction, acting as a switch for electrical signals. It acts as a one-way valve for electrons, allowing them to move from the diode’s anode (positive terminal) to the cathode (negative terminal), but preventing their reverse flow.

Diodes are commonly used in a wide range of electronic applications. They can be found in everything from power supplies and rectifiers in electronic devices to signal demodulation in communication systems and voltage regulation in power management circuits.

One of the key characteristics of a diode is its forward voltage drop, which is typically around 0.7 volts for silicon diodes. This means that when a diode is forward-biased (connected with the positive side of the circuit on its anode and the negative side on its cathode), it allows current to flow through it, provided the voltage across the diode exceeds the threshold voltage.

In contrast, when a diode is reverse-biased (connected with the negative side on its anode and the positive side on its cathode), it acts as an insulator, blocking the flow of current. The reverse-bias voltage must exceed a certain threshold, known as the breakdown voltage, for the diode to start conducting in reverse mode.

Overall, diodes are essential components in electronic circuits, enabling the efficient control and manipulation of electrical currents. Understanding their behavior and how they are utilized in various circuits is crucial for any electronics enthusiast or engineer.

How Does a Diode Work?

A diode operates based on the principle of a junction formed between two different types of semiconductor materials: P-type and N-type. This junction is called the P-N junction, which forms the core of a diode’s functionality.

The P-N junction consists of a region with excess valence electrons (N-type material) and a region with an absence of valence electrons (P-type material). This creates a natural potential barrier between the two regions, known as the depletion region. The depletion region prevents the flow of current under normal conditions.

When a diode is forward-biased, meaning the anode is connected to a higher positive voltage and the cathode to a lower positive voltage (ground or negative terminal), the potential difference across the P-N junction decreases. This reduction in the potential barrier width allows current to flow through the diode.

As current flows from the P-type region to the N-type region, the excess electrons in the N-type material combine with the holes (electron-deficient areas) in the P-type material, neutralizing each other. This process is known as recombination.

The result of recombination is the creation of a conducting path where charge carriers (electrons and holes) can move easily, facilitating the flow of current through the diode.

On the other hand, when a diode is reverse-biased, meaning the anode is connected to a lower positive voltage and the cathode to a higher positive voltage, the potential difference across the P-N junction increases. This widens the depletion region, effectively blocking the flow of current. The diode acts as an insulator in this state.

It is important to note that while a diode ideally acts as a perfect one-way valve for current, there may be a slight leakage current in reverse-bias mode due to imperfections in the diode’s construction.

Purpose of Diodes in Electrical Circuits

Diodes serve various essential purposes in electrical circuits, enabling them to function effectively and efficiently. Understanding the key roles of diodes can help in designing and optimizing circuit performance.

One of the primary purposes of diodes is to rectify alternating current (AC) into direct current (DC). AC is a form of electrical current that periodically changes direction, while DC flows consistently in one direction. By placing a diode in the circuit in a specific configuration, it can allow current to flow in only one direction, converting the AC signal into a DC signal.

Diodes are also commonly used for voltage regulation. They can maintain a stable voltage level by preventing voltage spikes or exceeding a certain threshold. Zener diodes, which have a specific breakdown voltage, are often employed in voltage regulation circuits to provide a consistent output voltage even when the input voltage fluctuates.

Another purpose of diodes is signal processing and modulation. Diodes can be used to demodulate signals in radio and communication systems. In this context, diodes act as rectifiers, extracting the original information from the modulated carrier signal.

Furthermore, diodes play a crucial role in protecting electronic components from reverse current flow or voltage spikes. By placing diodes in reverse-biased configuration, they can act as clamping or protection diodes, shunting excessive voltage away from sensitive components and preventing damage.

Light-emitting diodes (LED) are a special type of diode that emit light when forward-biased. They are widely used in lighting applications, display panels, and indicators due to their energy efficiency, long lifespan, and ability to emit light in a variety of colors.

Diodes are also utilized in the field of switching and logic circuits. They enable the manipulation of digital signals, allowing for the implementation of logical operations and data processing for various electronic devices, such as computers and microcontrollers.

Overall, diodes serve as key components in electrical circuits, fulfilling critical functions such as rectification, voltage regulation, signal processing, protection, lighting, and logical operations. Their versatility and wide range of applications make them indispensable in modern electronic systems.

Types of Diodes

Diodes come in various types, each designed to fulfill specific requirements and applications in electronic circuits. Let’s explore some of the common types of diodes:

1. Rectifier Diode: Rectifier diodes are primarily used for converting alternating current (AC) to direct current (DC). They have a high current carrying capacity and are capable of handling fast switching speeds.

2. Zener Diode: Zener diodes are utilized for voltage regulation in electronic circuits. They have a specific breakdown voltage called the Zener voltage, at which they exhibit a sharp change in conductivity, allowing current to flow in the reverse direction.

3. Light-Emitting Diode (LED): LEDs are diodes that emit light when forward-biased. They are widely used in lighting applications, displays, and indicators due to their energy efficiency and ability to produce various colors of light.

4. Photodiode: Photodiodes are light-sensitive diodes that generate an electric current when exposed to light. They are commonly used in applications such as light detectors, optical communication systems, and solar panels.

5. Schottky Diode: Schottky diodes have a low forward voltage drop and fast switching characteristics. They are often used in high-speed applications, power supplies, and rectifiers where minimizing power losses is crucial.

6. Varactor Diode: Varactor diodes, also known as voltage-controlled capacitors or varicaps, are designed to act as variable capacitors. Their capacitance varies with the applied voltage, making them ideal for applications in tuning and frequency control circuits.

7. Tunnel Diode: Tunnel diodes are characterized by their ability to exhibit negative resistance. They are used in microwave applications, high-frequency oscillators, and signal amplifiers.

8. PN Junction Diode: The standard diode, also known as the PN junction diode, is the most common type found in electronic circuits. It consists of a P-type and N-type material junction and is used in various applications, including rectification, signal processing, and protection.

These are just a few examples of the many diode types available. Each type has specific characteristics and applications, allowing engineers and designers to select the most suitable diode for their intended purpose.

Semiconductors and P-N Junctions

In order to understand how diodes work, it is crucial to grasp the concept of semiconductors and the formation of P-N junctions.

Semiconductors are materials that have an intermediate level of electrical conductivity, higher than insulators (such as rubber or wood) but lower than conductors (such as copper or aluminum). Common semiconductor materials include silicon (Si) and germanium (Ge).

In pure form, semiconductors have a balanced number of positive and negative charges, resulting in a neutral charge overall. However, by adding impurities (known as doping) to the semiconductor material, its electrical properties can be modified.

The two most common types of doping are:

1. N-type Doping: This involves introducing impurities with extra valence electrons, such as phosphorus or arsenic. These extra electrons become the majority carriers, increasing the conductivity of the material.

2. P-type Doping: This involves introducing impurities with fewer valence electrons, such as boron or gallium. These impurities create electron-deficient areas called “holes” which act as the majority carriers.

When a P-type semiconductor and an N-type semiconductor are brought into contact, a P-N junction is formed. This junction acts as a barrier to the flow of current under normal conditions.

At the P-N junction, the electrons from the N-type region and the holes from the P-type region diffuse across the junction, creating a region with no free carriers known as the depletion region.

The depletion region contains immobile positive and negative charges, forming an electric field that prevents further migration of carriers. This creates a potential barrier between the P-type and N-type regions, blocking the flow of current.

When a voltage is applied across the P-N junction in a specific direction (forward-biased), the potential barrier is reduced, allowing current to flow across the junction. However, when the voltage is reversed (reverse-biased), the barrier widens, preventing significant current flow.

The behavior of the P-N junction and its ability to control the flow of current is fundamental to the operation of diodes and many other semiconductor devices.

Working Principle of Different Diode Types

Diodes are available in a variety of types, each with its own unique working principle. Let’s explore some of the common diode types and how they operate:

1. Rectifier Diode: Rectifier diodes are specifically designed for converting alternating current (AC) into direct current (DC). They work by allowing current to flow in only one direction, from the anode to the cathode when forward-biased. This enables them to rectify the AC signal by converting it into a pulsating DC signal.

2. Zener Diode: Zener diodes have a unique behavior when reverse-biased near their breakdown voltage, known as the Zener voltage. Instead of blocking the flow of current like a regular diode, they conduct heavily in the reverse direction, allowing a controlled current to flow when the reverse bias voltage exceeds the Zener voltage. This makes them ideal for voltage regulation and voltage clamping applications.

3. Light-Emitting Diode (LED): LEDs emit light when forward-biased. They are made from a special semiconductor material that releases energy in the form of light when electrons recombine with holes. The specific materials and doping used determine the color of light emitted. LEDs are used in a wide range of applications, including lighting, displays, and indicators.

4. Photodiode: Photodiodes are designed to generate a current when exposed to light. They operate by absorbing photons, which causes the generation of electron-hole pairs. The resulting current is directly proportional to the intensity of the incident light. Photodiodes are commonly used in applications such as light detection, optical communication, and solar panels.

5. Schottky Diode: Schottky diodes have a unique construction that utilizes the metal-semiconductor junction. They have a very low forward voltage drop and fast switching characteristics. Schottky diodes operate by creating a barrier at the metal-semiconductor junction, which allows for efficient and rapid switching of current. They are commonly used in high-frequency applications and power rectification.

6. Varactor Diode: Varactor diodes, also known as voltage-controlled capacitors, act as variable capacitors whose capacitance varies with the applied voltage. They exploit the depletion region’s width modulation at the P-N junction under reverse bias condition. Varactor diodes are commonly used in tuning circuits, frequency control, and voltage-controlled oscillators.

Each type of diode has a specific working principle that allows it to perform its intended function in electronic circuits. Understanding the intricacies of these different principles is crucial for selecting the appropriate diode for a specific application.

Common Diode Applications

Diodes find widespread use in a variety of electronic applications due to their unique properties and functionalities. Let’s explore some of the common applications where diodes play a crucial role:

1. Rectification: One of the primary applications of diodes is rectifying alternating current (AC) into direct current (DC). Diodes allow current to flow in one direction while blocking it in the opposite direction, enabling the conversion of AC signals to DC signals. This rectification process is essential in power supplies and battery chargers.

2. Voltage Regulation: Diodes, particularly Zener diodes, are employed in voltage regulation circuits. By maintaining a constant voltage level, they ensure the stability and protection of sensitive electronic components and circuits. Zener diodes are used in voltage regulators, voltage references, and power management applications.

3. Signal Demodulation: Diodes play a key role in demodulating signals in communication systems. They are used to extract the original information from modulated carrier signals, allowing for the decoding of audio, video, and data signals in applications such as radio receivers and telecommunications.

4. Protection and Clamping: Diodes are employed to protect sensitive components from voltage spikes and transient events. Zener diodes and TVS (Transient Voltage Suppression) diodes are often used to limit the voltage across critical components, preventing damage from overvoltages and reverse voltages. They act as clamps to divert excessive energy away from the protected components.

5. Lighting: Light-emitting diodes (LEDs) are extensively used for lighting applications. Due to their energy efficiency, long lifespan, and ability to emit a wide range of colors, LEDs are used in various lighting sources, including residential lighting, automotive lighting, display panels, and indicators.

6. Logic Gates and Digital Circuits: Diodes are employed in the construction of logic gates and digital circuits. They play a crucial role in implementing logical operations and data processing, forming the basis of digital electronics. Diodes are used in diode-based logic gates like AND, OR, and NOT gates.

7. Solar Energy Harvesting: Photovoltaic (PV) cells, also known as solar cells, are essentially large-area photodiodes that convert sunlight into electricity. By utilizing the photovoltaic effect, sunlight striking the diode’s surface generates a flow of electrons, creating an electric current. PV cells are used in solar panels to harness renewable energy from the sun.

These are just a few examples of the countless applications where diodes play a crucial role. Their versatility makes them essential components in a wide range of electronic circuits, enabling various functionalities and ensuring the efficient operation of electronic devices and systems.

Diode Specifications and Characteristics

Diodes are characterized by various specifications and characteristics that determine their performance and suitability for specific applications. Understanding these specifications is essential for selecting the right diode for a particular circuit. Let’s explore some of the key specifications and characteristics of diodes:

1. Forward Voltage Drop: The forward voltage drop is the voltage required to overcome the barrier and allow current to flow through the diode. It is typically around 0.7 volts for silicon diodes. Different diode types may have varying forward voltage drop values, and this specification is crucial for determining the power dissipation and efficiency of a diode in a circuit.

2. Reverse Breakdown Voltage: The reverse breakdown voltage is the voltage at which the diode starts conducting in the reverse direction. It represents the maximum voltage the diode can withstand without getting damaged. Zener diodes, in particular, have a well-defined breakdown voltage called the Zener voltage, which is utilized in voltage regulation circuits.

3. Maximum Current Rating: The maximum current rating specifies the maximum allowable current that can flow through the diode without causing damage. Exceeding this rating can lead to overheating and even permanent failure of the diode. It is important to ensure that the current flowing through the diode remains within its specified limits for reliable operation.

4. Reverse Recovery Time: The reverse recovery time is the time taken by a diode to transition from conducting in the forward direction to blocking the reverse current flow. It is a crucial parameter in fast switching applications, as a longer recovery time can lead to increased power dissipation and reduced efficiency.

5. Temperature Range: Diodes have specific temperature ranges within which they can operate reliably. Operating outside this temperature range may affect the diode’s performance and longevity. It is important to consider the ambient temperature and the temperature generated within the circuit to ensure that the diode remains within its rated temperature limits.

6. Diode Capacitance: Diodes have an inherent capacitance that affects their high-frequency response. This capacitance can limit the speed of switching operations and impact the performance of high-frequency circuits. Understanding the diode’s capacitance specifications is vital for designing circuits that require fast switching or operate in high-frequency environments.

7. Package Type: Diodes come in various package types, such as through-hole and surface mount, which determine their physical form and mounting options. The package choice depends on the specific circuit design and manufacturing requirements.

These are just a few of the many specifications and characteristics that define the behavior and performance of diodes. Considering these parameters allows designers and engineers to select the appropriate diodes for their applications, ensuring optimal circuit performance and reliability.

Forward and Reverse Bias

Forward and reverse bias are two fundamental modes of operation for diodes. Understanding these biasing conditions is crucial for understanding the behavior and characteristics of diodes. Let’s delve into the concepts of forward and reverse bias:

1. Forward Bias

Forward bias occurs when the positive terminal of the voltage source is connected to the diode’s P-region (anode) and the negative terminal to the N-region (cathode). This biasing arrangement allows the diode to conduct current, as it reduces the potential barrier at the P-N junction, known as the depletion region.

When forward biased, the positive voltage pushes the majority charge carriers (holes in the P-region and electrons in the N-region) towards the junction, narrowing the depletion region. This reduction in the barrier width facilitates the flow of current through the diode.

The forward voltage drop, typically around 0.7 volts for silicon diodes, is required to overcome the remaining potential barrier within the diode. As long as the forward bias voltage is greater than this threshold, the diode will allow current to flow freely in the forward direction.

2. Reverse Bias

Reverse bias occurs when the positive terminal of the voltage source is connected to the diode’s N-region (cathode), and the negative terminal is connected to the P-region (anode). In this configuration, the applied voltage increases the potential barrier, widening the depletion region and preventing significant current flow.

Under reverse bias conditions, the diode acts as an insulator, blocking the flow of majority carriers across the P-N junction. However, there can be a small leakage current due to minority charge carriers and other factors, but it is usually negligible.

If the reverse bias voltage exceeds a specific threshold, known as the reverse breakdown voltage, the diode can enter the reverse breakdown region. In this region, the diode’s characteristics change, and it starts conducting heavily in the reverse direction, potentially resulting in damage to the diode.

Understanding forward and reverse bias is vital for designing circuits and controlling the flow of current through diodes. It allows engineers to harness the unique characteristics of diodes for rectification, voltage regulation, signal processing, and other applications in electronic systems.

Diode Voltage Drop and Current Flow

Diode voltage drop and current flow are crucial characteristics that determine the behavior and functionality of diodes in electronic circuits. Let’s explore how diode voltage drop and current flow are interconnected:

1. Voltage Drop

The voltage drop across a diode refers to the voltage required to overcome the diode’s forward bias and allow current to flow through it. In a typical silicon diode, the voltage drop is around 0.7 volts when forward-biased.

The forward voltage drop is an inherent property of diodes and arises due to the potential barrier at the P-N junction. This barrier prevents current flow until the applied voltage reaches a certain threshold, known as the diode’s turn-on voltage.

When the forward bias voltage exceeds the turn-on voltage, the diode conducts and the voltage drop across it remains relatively constant. This voltage drop is utilized in rectification circuits and power supply applications to convert alternating current (AC) into direct current (DC).

It is important to consider the diode’s voltage drop in circuit design to ensure that the power supply and voltage requirements are met. Different diode types may have varying voltage drop values, so it’s essential to select the appropriate diode for the intended application.

2. Current Flow

The flow of current through a diode depends on the biasing condition and the voltage applied across the diode.

Forward Bias: When a diode is forward-biased, current flows easily through the diode in the forward direction. The majority charge carriers (holes in the P-region and electrons in the N-region) move across the P-N junction, creating a conducting path for the current. The magnitude of the current flow increases with the applied voltage, as long as the forward voltage drop is overcome.

Reverse Bias: When a diode is reverse-biased, the potential barrier widens, and current flow is significantly restricted. The diode acts as an insulator, preventing the flow of majority carriers across the P-N junction. Only a small leakage current, called the reverse leakage current, flows due to the presence of minority charge carriers and other factors. This leakage current is typically very low and can often be ignored in most applications.

It’s important to note that exceeding the diode’s maximum current rating in either forward or reverse bias can lead to overheating and even permanent damage to the diode. Therefore, designing the circuit with appropriate current limiting measures is necessary to ensure the long-term reliability of the diode.

Understanding the relationship between diode voltage drop and current flow is crucial for selecting the right diode for a specific application and designing circuits that operate within the diode’s specified voltage and current limits.

Diode Ratings and Parameters

Diode ratings and parameters provide crucial information about the electrical limitations and specifications of diodes. Understanding these ratings is essential for selecting the right diode and designing circuits that operate reliably. Let’s explore some of the common diode ratings and parameters:

1. Maximum Forward Current (IF): This rating specifies the maximum allowable current that can safely flow through the diode when forward-biased. Exceeding this rating can lead to overheating and potentially damage the diode. It is important to ensure that the current flowing through the diode remains within its specified limits to maintain reliable operation.

2. Maximum Reverse Voltage (VR): The maximum reverse voltage rating indicates the maximum voltage that can be applied across the diode in the reverse-biased condition without causing damage. Operating beyond this voltage limit can result in high reverse current and potential breakdown of the diode.

3. Power Dissipation (PD): The power dissipation rating represents the maximum amount of power that the diode can safely dissipate without exceeding its maximum junction temperature. It is important to consider the power dissipation when designing circuits to prevent excessive heat buildup and ensure the longevity of the diode.

4. Maximum Junction Temperature (Tj): The maximum junction temperature rating specifies the maximum temperature that the diode’s junction can safely reach without causing damage. Operating the diode beyond this temperature can result in thermal stress and degradation of the diode’s performance and reliability.

5. Reverse Current (IR): Reverse current, also known as leakage current, is the current that flows through a diode when it is reverse-biased. It is typically very low, but it is important to consider, especially in applications where low currents are critical, such as sensor circuits or low-power devices.

6. Reverse Recovery Time (trr): Reverse recovery time refers to the time it takes for a diode to transition from conducting in the forward direction to blocking in the reverse direction when the polarity of the applied voltage across the diode changes. A shorter reverse recovery time is desirable in high-speed switching applications to minimize switching losses and improve efficiency.

7. Capacitance (C): Diodes have an inherent capacitance between their terminals, which can influence their performance in high-frequency applications. The capacitance affects the diode’s ability to respond to rapid voltage changes and can be a critical parameter in applications such as high-speed data transmission or radio frequency circuits.

8. Package Type: The package type refers to the physical enclosure and mounting style of the diode. Different package types have different form factors, lead arrangements, and mounting options, which can impact the circuit board layout and assembly process.

These are some of the key diode ratings and parameters to consider when selecting and designing with diodes. Taking these specifications into account ensures proper operation and reliability of diodes in various electronic applications.

Diode Testing and Troubleshooting

Diode testing and troubleshooting are essential processes to ensure the proper functioning of diodes in electronic circuits. Let’s explore some common methods and techniques for diode testing and troubleshooting:

1. Visual Inspection: Start by visually inspecting the diode for any physical damage, such as cracks, discoloration, or loose connections. Faulty diodes may exhibit visible signs of damage that can indicate a problem.

2. Forward and Reverse Bias Testing: Utilize a multimeter to test the diode’s forward and reverse bias behavior. In forward bias, the diode should conduct and show a low resistance reading in one direction, while in reverse bias, it should block the current flow and display a high resistance reading.

3. Continuity Testing: Diodes should only conduct in one direction, while in the reverse direction, they should display high resistance. Use a multimeter’s continuity test or resistance mode to check for continuity and ensure proper diode behavior.

4. Reverse Breakdown Voltage Testing: If the diode is a Zener diode or has a specified reverse breakdown voltage, test it using a power supply and a series resistor. Gradually increase the reverse bias voltage and monitor the current. The diode should start conducting around its specified reverse breakdown voltage.

5. Replacement Testing: Substituting a suspected faulty diode with a known good diode can help identify if the original diode is indeed the problem. If the circuit functions properly with the replacement diode, it confirms the faulty nature of the original diode.

6. Thermal Testing: Some diode failures can be caused by excessive heat. Use a thermal imaging camera or a thermometer to check the temperature of the diode during operation. If the diode is running significantly hotter than expected, it may indicate a problem such as excessive current or insufficient heat dissipation.

7. Diode Parameter Comparison: Compare the measured characteristics of the diode, such as forward voltage drop or reverse leakage current, with the manufacturer’s specifications. If the measured values deviate significantly from the expected values, it indicates a potential issue with the diode.

8. Circuit Analysis: Analyze the circuit surrounding the diode to identify any potential issues, such as incorrect connections, short circuits, or incorrect biasing. Ensure that the diode is being correctly utilized within the circuit and that the overall circuit design is appropriate for the application.

In troubleshooting diode-related issues, it’s important to follow proper safety measures, such as disconnecting power sources and wearing appropriate protective equipment. Additionally, consulting datasheets, technical resources, or seeking guidance from experienced professionals can provide further insights into resolving diode-related problems.

Diode Packaging and Mounting

Diode packaging and mounting play a crucial role in ensuring the functionality and reliability of diodes in electronic circuits. Let’s explore some important considerations regarding diode packaging and mounting:

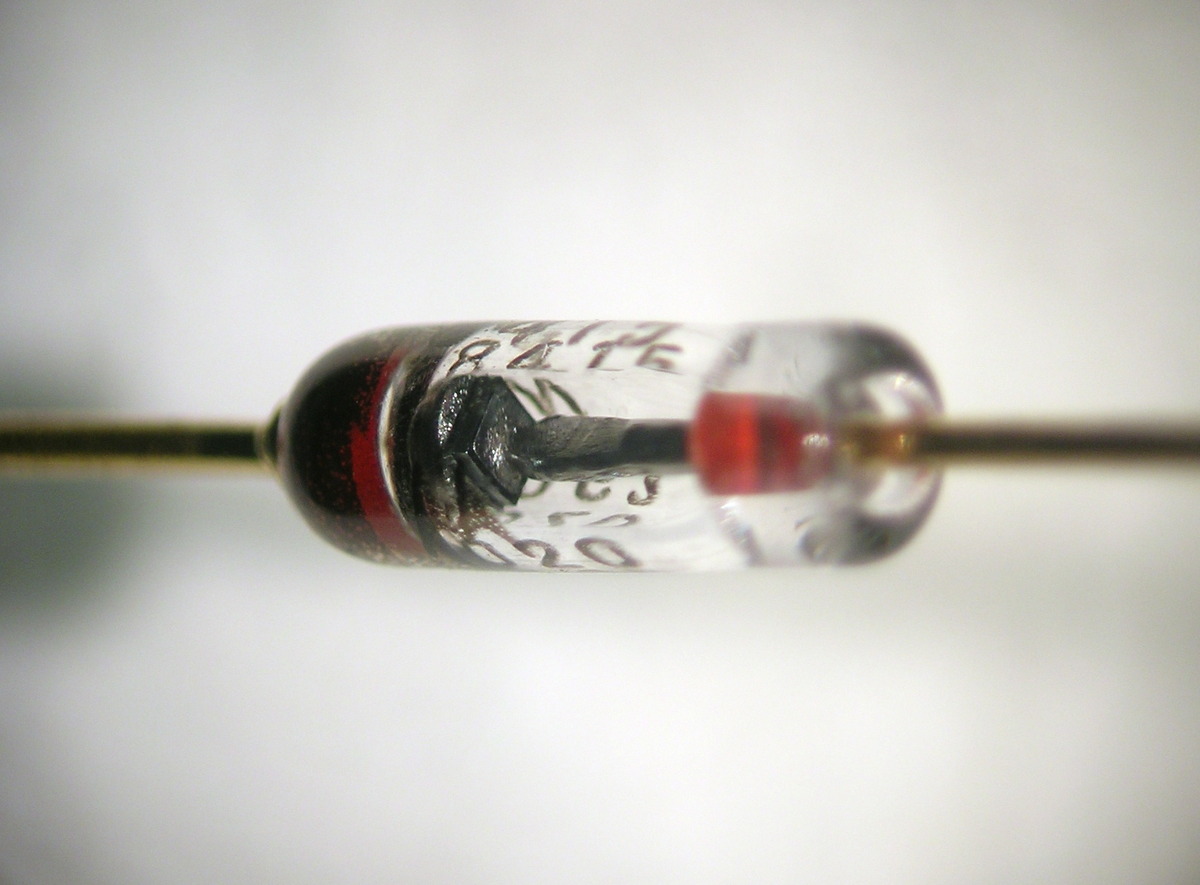

1. Package Types: Diodes are available in various package types, each with its own form factor, lead arrangement, and mechanical characteristics. Common diode package types include through-hole packages (such as DO-41, DO-15, and TO-220) and surface mount packages (such as SOD-123, SOT-23, and QFN). The selection of the package type depends on factors such as board space, assembly process, and environmental requirements.

2. Lead Configuration: Diodes can have different lead configurations, including axial leads, radial leads, or surface mount leads. Axial lead diodes have leads extending from opposite ends, while radial lead diodes have leads extending from the same side in a circular pattern. Surface mount diodes have flat leads that are soldered directly onto the circuit board. Choose the appropriate lead configuration based on the specific application and assembly method.

3. Mounting Techniques: Proper mounting techniques are essential to ensure the diode is securely attached to the circuit board for efficient heat dissipation and electrical connections. Through-hole diodes are typically soldered into place using through-hole soldering techniques. Surface mount diodes are soldered onto the surface of the circuit board using surface mount soldering techniques, such as reflow soldering or hand soldering with a soldering iron or hot air rework station.

4. Thermal Considerations: Diodes generate heat during operation, and efficient heat dissipation is crucial for their reliability. Proper thermal management includes the use of heat sinks, thermal pads or compounds, and proper airflow around the diode. The diode’s thermal resistance junction-to-ambient (RθJA) or junction-to-case (RθJC) should be considered to ensure the diode operates within its specified temperature limits.

5. Protection and Encapsulation: Some diodes, especially those used in harsh environments, may require additional protection. In such cases, diodes can be encapsulated with protective materials, coatings, or enclosures to safeguard them against moisture, dust, vibration, or other environmental factors. This is particularly important for diodes used in automotive, aerospace, or industrial applications.

6. Markings and Identification: Diodes typically have markings or labels on their body to provide identification and information about the diode, such as the manufacturer, part number, or specifications. These markings help in identification, documentation, and troubleshooting of the diode on the circuit board.

When working with diode packaging and mounting, it is important to follow the manufacturer’s guidelines and recommended practices. Adhering to proper mounting techniques and ensuring adequate thermal management will help maintain the performance and longevity of the diode in the circuit.