Inspecting the Connector

Before testing a trailer connector, it’s crucial to inspect the connector itself. The connector is the crucial link between the towing vehicle and the trailer, facilitating the transfer of power and signals necessary for safe and legal towing. Here are the steps to follow when inspecting the connector:

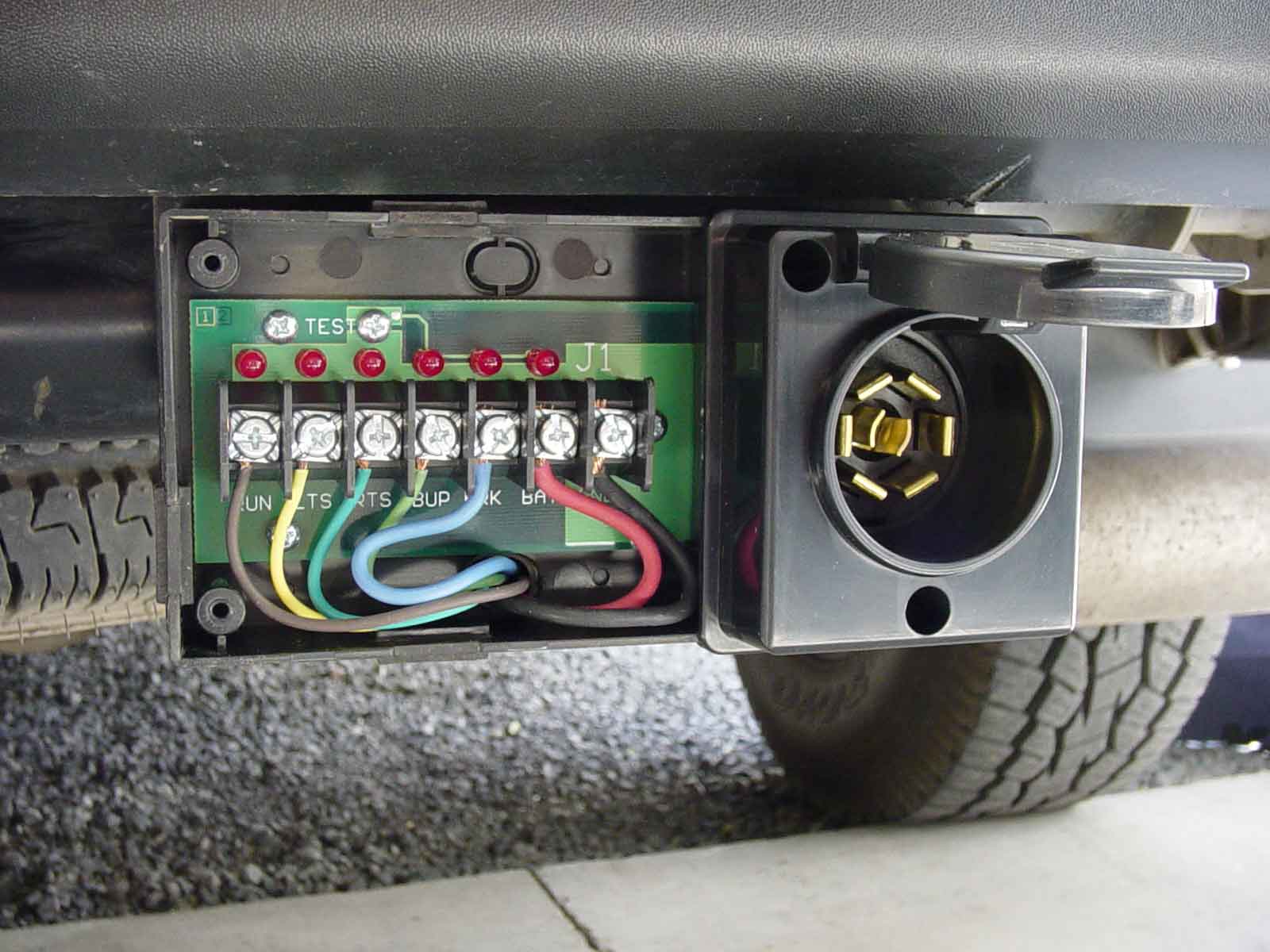

- Visual Examination: Begin by visually examining the connector for any signs of damage, such as cracks, dents, or exposed wires. Any visible damage could indicate potential issues with the connector’s functionality and should be addressed promptly.

- Secure Attachment: Ensure that the connector is securely attached to the vehicle. A loose or improperly attached connector may result in unreliable electrical connections, leading to problems with the trailer’s lights and brakes.

- Cleanliness: Check for any dirt, debris, or corrosion within the connector. Dirt and debris can impede electrical connections, while corrosion can cause electrical resistance, leading to malfunctions in the trailer’s lighting system.

- Proper Terminal Alignment: Verify that the connector’s terminals are aligned correctly. Misaligned terminals can lead to poor electrical contact, affecting the performance of the trailer’s lights and brakes.

- Secure Wiring: Inspect the wiring connected to the trailer connector for any signs of wear, fraying, or damage. Damaged wiring can compromise the electrical connection and pose safety hazards during towing.

By meticulously inspecting the trailer connector, you can identify and address any potential issues that may affect its functionality. This proactive approach ensures that the towing vehicle and trailer remain safely connected, minimizing the risk of electrical malfunctions during transit.

Checking for Corrosion

Corrosion can significantly impede the functionality of a trailer connector, leading to electrical malfunctions and safety hazards. It is essential to thoroughly check for corrosion and address any issues promptly. Follow these steps to check for corrosion in the trailer connector:

- Visual Inspection: Begin by visually examining the connector for any signs of corrosion. Corrosion often appears as a greenish or bluish residue on the metal surfaces, indicating oxidation.

- Cleaning the Terminals: If corrosion is present, carefully clean the terminals using a suitable electrical contact cleaner or a mixture of baking soda and water. Gently scrub the affected areas to remove the corrosion, ensuring that the terminals are free from any oxidized residue.

- Applying Dielectric Grease: After cleaning, apply a thin layer of dielectric grease to the terminals. Dielectric grease helps prevent future corrosion by creating a protective barrier against moisture and contaminants.

- Inspecting the Wiring: Check the wiring connected to the trailer connector for any signs of corrosion or damage. Corroded wiring should be replaced to maintain reliable electrical connections.

- Protective Measures: Consider using weatherproofing products, such as heat shrink tubing or electrical tape, to protect the connector and wiring from moisture and environmental elements, reducing the risk of corrosion.

Regularly checking for and addressing corrosion in the trailer connector is essential for maintaining a reliable electrical connection between the towing vehicle and the trailer. By taking proactive measures to combat corrosion, you can ensure the safety and functionality of the trailer’s lighting and braking systems, promoting a secure towing experience.

Testing the Ground Connection

Ensuring a solid ground connection is crucial for the proper functioning of a trailer’s electrical system. A faulty ground connection can lead to various lighting and brake issues, compromising safety during towing. Here’s how to effectively test the ground connection of a trailer:

- Visual Inspection: Begin by visually examining the ground wire connected to the trailer’s electrical system. Check for any signs of damage, corrosion, or loose connections. A secure and corrosion-free ground wire is essential for reliable electrical grounding.

- Using a Multimeter: Employ a multimeter to test the continuity between the ground wire and the trailer frame. Set the multimeter to measure resistance and place one probe on the ground wire’s terminal and the other on a clean metal surface of the trailer frame. A low resistance reading indicates a solid ground connection.

- Ensuring Secure Attachment: Verify that the ground wire is securely attached to the trailer frame. Any looseness or detachment can lead to an unreliable ground connection, resulting in erratic behavior of the trailer’s lights and brakes.

- Cleaning and Securing the Ground Connection: If corrosion is present on the ground wire or the attachment point, carefully clean the affected areas and ensure a secure, corrosion-free connection. Applying dielectric grease after cleaning can help prevent future corrosion and maintain a reliable ground connection.

- Testing Grounded Components: Test the trailer lights and brakes to confirm that they are functioning correctly after addressing any ground connection issues. Properly grounded components will operate consistently and effectively.

By meticulously testing and maintaining the ground connection of a trailer’s electrical system, you can mitigate the risk of lighting and brake malfunctions, promoting safer towing experiences. A reliable ground connection is fundamental to the overall functionality and safety of the trailer’s electrical components.

Testing the Brake Lights

Ensuring the proper functionality of a trailer’s brake lights is essential for safe towing, as they communicate braking intentions to other drivers on the road. Testing the brake lights is a crucial step in maintaining road safety. Follow these steps to effectively test the brake lights of a trailer:

- Activating the Tow Vehicle’s Brake Pedal: Have an assistant activate the tow vehicle’s brake pedal while you observe the trailer’s brake lights. The brake lights should illuminate brightly and consistently when the brake pedal is depressed. If the lights appear dim or flicker, there may be an issue with the electrical connection or the bulbs themselves.

- Inspecting the Bulbs: If the brake lights do not illuminate as expected, inspect the bulbs for signs of damage or burnout. Replace any faulty bulbs with the appropriate replacements, ensuring a secure and proper fit within the light sockets.

- Testing the Brake Light Circuit: Utilize a circuit tester to check the electrical continuity within the brake light circuit. Confirm that the wiring, connectors, and switches associated with the brake lights are functioning correctly and transmitting electrical signals effectively.

- Checking the Brake Light Fuse: Inspect the fuse dedicated to the trailer’s brake lights to ensure it is intact. A blown fuse can disrupt the electrical supply to the brake lights, leading to their malfunction. Replace the fuse if necessary with one of the same amperage rating.

- Verifying Proper Grounding: Ensure that the ground connection for the trailer’s brake lights is secure and free from corrosion. A solid ground connection is vital for the consistent operation of the brake lights.

By meticulously testing the brake lights and addressing any issues promptly, you can uphold the safety and visibility of the trailer on the road. Properly functioning brake lights contribute to clear communication of braking actions, enhancing overall road safety during towing.

Testing the Turn Signals

Properly functioning turn signals on a trailer are essential for indicating intended changes in direction, enhancing road safety for both the towing vehicle and other motorists. Testing the turn signals ensures that they are operational and visible to surrounding drivers. Follow these steps to effectively test the turn signals of a trailer:

- Activating the Tow Vehicle’s Turn Signals: Request an assistant to activate the turn signals on the towing vehicle while you observe the trailer’s turn signal lights. The turn signals on the trailer should flash in synchronization with the vehicle’s signals, indicating their proper functionality.

- Inspecting the Signal Bulbs: If the turn signals do not operate as expected, inspect the signal bulbs for signs of damage or burnout. Replace any faulty bulbs with the appropriate replacements, ensuring a secure and proper fit within the light sockets.

- Testing the Turn Signal Circuit: Utilize a circuit tester to check the electrical continuity within the turn signal circuit. Confirm that the wiring, connectors, and switches associated with the turn signals are functioning correctly and transmitting electrical signals effectively.

- Checking the Turn Signal Fuse: Inspect the fuse dedicated to the trailer’s turn signals to ensure it is intact. A blown fuse can disrupt the electrical supply to the turn signals, leading to their malfunction. Replace the fuse if necessary with one of the same amperage rating.

- Verifying Proper Grounding: Ensure that the ground connection for the trailer’s turn signals is secure and free from corrosion. A solid ground connection is vital for the consistent operation and visibility of the turn signals.

Thoroughly testing the turn signals and promptly addressing any issues ensures that the trailer effectively communicates intended turns and lane changes, contributing to overall road safety. Well-maintained turn signals enhance the visibility and predictability of the trailer’s movements, promoting a secure towing experience.

Testing the Running Lights

Properly functioning running lights on a trailer are essential for maintaining visibility and safety, especially during low-light conditions or nighttime towing. Testing the running lights ensures that they are operational and visible to other motorists on the road. Here are the steps to effectively test the running lights of a trailer:

- Activating the Tow Vehicle’s Lights: Turn on the towing vehicle’s headlights to activate the trailer’s running lights. The running lights should illuminate consistently and evenly along the length of the trailer, enhancing its visibility to other drivers.

- Inspecting the Light Housings: Visually inspect the running light housings for signs of damage, moisture ingress, or loose connections. Damaged or improperly connected housings can lead to irregular illumination or complete failure of the running lights.

- Testing the Running Light Circuit: Use a circuit tester to check the electrical continuity within the running light circuit. Confirm that the wiring, connectors, and switches associated with the running lights are functioning correctly and transmitting electrical signals effectively.

- Checking the Running Light Fuse: Inspect the fuse dedicated to the trailer’s running lights to ensure it is intact. A blown fuse can disrupt the electrical supply to the running lights, leading to their malfunction. Replace the fuse if necessary with one of the same amperage rating.

- Verifying Proper Grounding: Ensure that the ground connection for the trailer’s running lights is secure and free from corrosion. A solid ground connection is vital for the consistent operation and visibility of the running lights.

Thoroughly testing the running lights and promptly addressing any issues ensures that the trailer remains clearly visible to other motorists, promoting road safety during towing. Well-maintained running lights contribute to the overall visibility and presence of the trailer, particularly in low-light or nighttime driving conditions.

Testing the Electric Brakes

Electric brakes play a crucial role in enhancing the safety and control of a trailer during towing, particularly when navigating downhill slopes or making sudden stops. Testing the electric brakes ensures that they are operational and capable of effectively assisting in braking maneuvers. Here are the steps to effectively test the electric brakes of a trailer:

- Activating the Brake Controller: Engage the brake controller in the towing vehicle to apply the trailer’s electric brakes. The trailer should respond by applying braking force, noticeable through a reduction in speed and the absence of any jerking or swaying movements.

- Inspecting the Brake Assemblies: Visually inspect the electric brake assemblies for signs of damage, excessive wear, or loose connections. Damaged or worn brake components can compromise braking efficiency and should be addressed promptly.

- Testing Brake Engagement: Test the trailer’s electric brakes in a controlled environment, such as an empty parking lot, by gradually applying the brakes using the brake controller. The trailer should decelerate smoothly without any pulling to one side, indicating balanced brake engagement.

- Verifying Brake Adjustment: Ensure that the electric brakes are properly adjusted to provide consistent and proportional braking force. Imbalanced brake adjustment can lead to uneven braking and compromised control during towing.

- Checking the Brake Breakaway System: Test the trailer’s breakaway system, if equipped, by simulating a breakaway event. Verify that the electric brakes engage as intended when the breakaway switch is activated, ensuring an additional safety measure in the event of trailer detachment.

Thoroughly testing the electric brakes and promptly addressing any issues ensures that the trailer maintains optimal braking performance, contributing to overall towing safety and control. Well-maintained electric brakes enhance the trailer’s ability to respond effectively to braking commands, promoting a secure towing experience.

Testing the Reverse Lights

Reverse lights on a trailer are essential for providing visibility to other motorists and ensuring safe maneuvers when backing up. Testing the reverse lights confirms their proper functionality, contributing to overall road safety during towing. Here are the steps to effectively test the reverse lights of a trailer:

- Activating the Tow Vehicle’s Reverse Gear: With the towing vehicle in reverse gear, observe the trailer’s reverse lights to ensure they illuminate brightly and consistently. Properly functioning reverse lights provide crucial visibility to other drivers, indicating the trailer’s rearward movement.

- Inspecting the Light Housings: Visually inspect the reverse light housings for signs of damage, moisture ingress, or loose connections. Damaged or improperly connected housings can lead to irregular illumination or complete failure of the reverse lights.

- Testing the Reverse Light Circuit: Use a circuit tester to check the electrical continuity within the reverse light circuit. Confirm that the wiring, connectors, and switches associated with the reverse lights are functioning correctly and transmitting electrical signals effectively.

- Checking the Reverse Light Fuse: Inspect the fuse dedicated to the trailer’s reverse lights to ensure it is intact. A blown fuse can disrupt the electrical supply to the reverse lights, leading to their malfunction. Replace the fuse if necessary with one of the same amperage rating.

- Verifying Proper Grounding: Ensure that the ground connection for the trailer’s reverse lights is secure and free from corrosion. A solid ground connection is vital for the consistent operation and visibility of the reverse lights.

Thoroughly testing the reverse lights and promptly addressing any issues ensures that the trailer remains clearly visible to other motorists, promoting road safety during reversing maneuvers. Well-maintained reverse lights contribute to the overall visibility and predictability of the trailer’s movements, enhancing the towing experience.