What is Electronic Throttle Control?

Electronic Throttle Control (ETC) is a system in modern vehicles that replaces the traditional mechanical throttle linkage with electronic sensors and actuators. The purpose of ETC is to regulate the amount of air entering the engine and control the throttle opening accordingly. By doing so, it provides better fuel efficiency, smoother acceleration, and enhances overall engine performance.

In traditional throttle systems, a driver operates the throttle pedal directly, which is connected to the throttle body by a cable. However, in an ETC system, the throttle pedal position is measured by a sensor and sent to the engine control unit (ECU), which then commands the throttle actuator to open or close the throttle valve accordingly. This allows for more precise control over the engine’s air intake, optimizing combustion and reducing emissions.

One of the significant advantages of ETC is its ability to incorporate additional functions and features. For instance, many ETC systems include a fail-safe mode that limits engine power in the event of a sensor or actuator failure. This ensures that the vehicle remains operational while minimizing the risk of a sudden loss of power, enhancing driver safety.

ETC systems are also capable of implementing adaptive cruise control, traction control, and stability control, among other advanced driver assistance features. By integrating these functions with the throttle control, ETC improves overall vehicle performance and safety.

Overall, Electronic Throttle Control is a technologically advanced system that replaces the traditional mechanical throttle linkage, providing better engine performance, enhanced fuel efficiency, and added safety features. Understanding how the ETC system works and how to troubleshoot common issues can help vehicle owners maintain optimal performance and address any throttle control problems effectively.

Symptoms of Electronic Throttle Control Issues

Electronic Throttle Control (ETC) issues can manifest in various ways, and it’s important for vehicle owners to be aware of the common symptoms. Recognizing these signs can help identify potential throttle control problems and prompt timely repairs. Here are some of the most common symptoms:

- Reduced power: One of the primary indications of an ETC problem is a noticeable reduction in engine power. The vehicle may struggle to accelerate or feel sluggish during operation.

- Stalling: If the throttle control system is malfunctioning, the engine may stall unexpectedly, especially when idling or coming to a stop.

- Inconsistent acceleration: A faulty ETC system can result in an erratic throttle response, making it challenging to maintain a steady speed while driving.

- Unresponsive throttle: Another telltale sign of ETC issues is an unresponsive throttle pedal. It may feel stiff, require excessive force to respond, or exhibit delays in throttle input.

- Check Engine Light: When an ETC malfunction occurs, the Check Engine Light will typically illuminate on the dashboard. It serves as a warning and indicates that diagnostic trouble codes (DTCs) are stored in the vehicle’s ECU.

- Limp mode activation: In some cases, the ETC system may detect a severe fault and activate a “limp mode.” This protective measure limits the vehicle’s speed and power to prevent further damage.

It’s worth noting that while these symptoms are often indicative of ETC problems, they can also be associated with other issues, such as malfunctioning sensors or fuel delivery problems. Therefore, it’s crucial to perform a thorough diagnosis to pinpoint the exact cause of the symptoms.

If any of these symptoms persist or if the Check Engine Light illuminates, it is advisable to seek professional assistance. Trained technicians can utilize specialized diagnostic equipment to identify the specific ETC issue and recommend the appropriate repairs or replacements.

Common Causes of Electronic Throttle Control Problems

Electronic Throttle Control (ETC) problems can arise due to various factors. Understanding the common causes of these issues can help vehicle owners diagnose and address throttle control problems effectively. Here are some of the most frequent culprits:

- Dirty throttle body: Over time, carbon deposits and debris can accumulate in the throttle body, resulting in restricted airflow and causing ETC problems. This buildup can affect the throttle plate’s movement, leading to reduced engine performance and responsiveness.

- Failed throttle position sensor (TPS): The throttle position sensor is responsible for relaying the position of the throttle plate to the ECU. A malfunctioning TPS can result in incorrect throttle readings, leading to issues such as stalling, hesitations, and poor acceleration.

- Malfunctioning accelerator pedal position sensor (APP): The APP sensor detects the position of the accelerator pedal and sends the information to the ECU. If the APP sensor fails or becomes faulty, it can cause throttle control problems, resulting in unresponsive or erratic acceleration.

- Wiring or connector issues: Faulty wiring or loose connectors can interrupt the communication between the throttle control components and the ECU. This can lead to inconsistent signals and misinterpretation of throttle input, resulting in various ETC problems.

- Faulty throttle actuator: The throttle actuator controls the movement of the throttle plate based on commands from the ECU. A malfunctioning actuator can cause irregular throttle response, reduced power, or even total loss of throttle control.

- Software or programming issues: In some cases, ETC problems can be attributed to software glitches or programming errors within the vehicle’s ECU. These issues can cause incorrect throttle control algorithms and result in erratic throttle behavior.

Identifying the underlying cause of ETC problems can be challenging, as multiple factors can contribute to the symptoms. It’s essential to perform a thorough diagnosis, which may involve using specialized diagnostic equipment to read fault codes and perform system tests. Once the cause is determined, appropriate repairs or component replacements can be carried out to restore proper ETC functionality.

In the next section, we will explore the steps to check for error codes that can aid in diagnosing electronic throttle control issues.

Checking for Error Codes

When experiencing Electronic Throttle Control (ETC) issues, one of the first steps in diagnosing the problem is to check for error codes stored in the vehicle’s engine control unit (ECU). These codes can provide valuable insights into the specific ETC malfunction and guide the troubleshooting process. Here’s how to check for error codes:

- Use an OBD-II scanner: An On-Board Diagnostic (OBD-II) scanner is a handheld tool that can retrieve error codes from the vehicle’s ECU. Connect the scanner to the vehicle’s OBD-II port, typically located beneath the dashboard near the driver’s side, and follow the scanner’s instructions.

- Scan for codes: Once the scanner is connected, initiate a scan to retrieve the error codes. The scanner will communicate with the ECU and display any stored codes.

- Interpret the codes: Error codes are alphanumeric combinations that indicate specific issues within the ETC system. Refer to the OBD-II scanner’s manual or online resources to interpret the codes. Each code corresponds to a specific component or system malfunction.

- Document the codes: Record the error codes for reference during the troubleshooting process. Having a list of the codes will help identify the root cause of the ETC problem and guide the appropriate repairs.

Keep in mind that error codes alone do not always pinpoint the exact cause of the ETC issue. They provide a starting point for diagnosis and indicate which components or systems require further investigation. Therefore, it is important to perform additional tests and inspections based on the specific codes retrieved.

Some OBD-II scanners also provide the ability to clear error codes. However, it is recommended to consult with a professional or conduct further troubleshooting before clearing codes. Clearing codes without addressing the underlying problem may result in the ETC issue recurring.

In the next sections, we will explore various steps and techniques to address common Electronic Throttle Control problems, including cleaning the throttle body, replacing sensors, inspecting wiring, and calibrating the ETC system.

Cleaning the Throttle Body

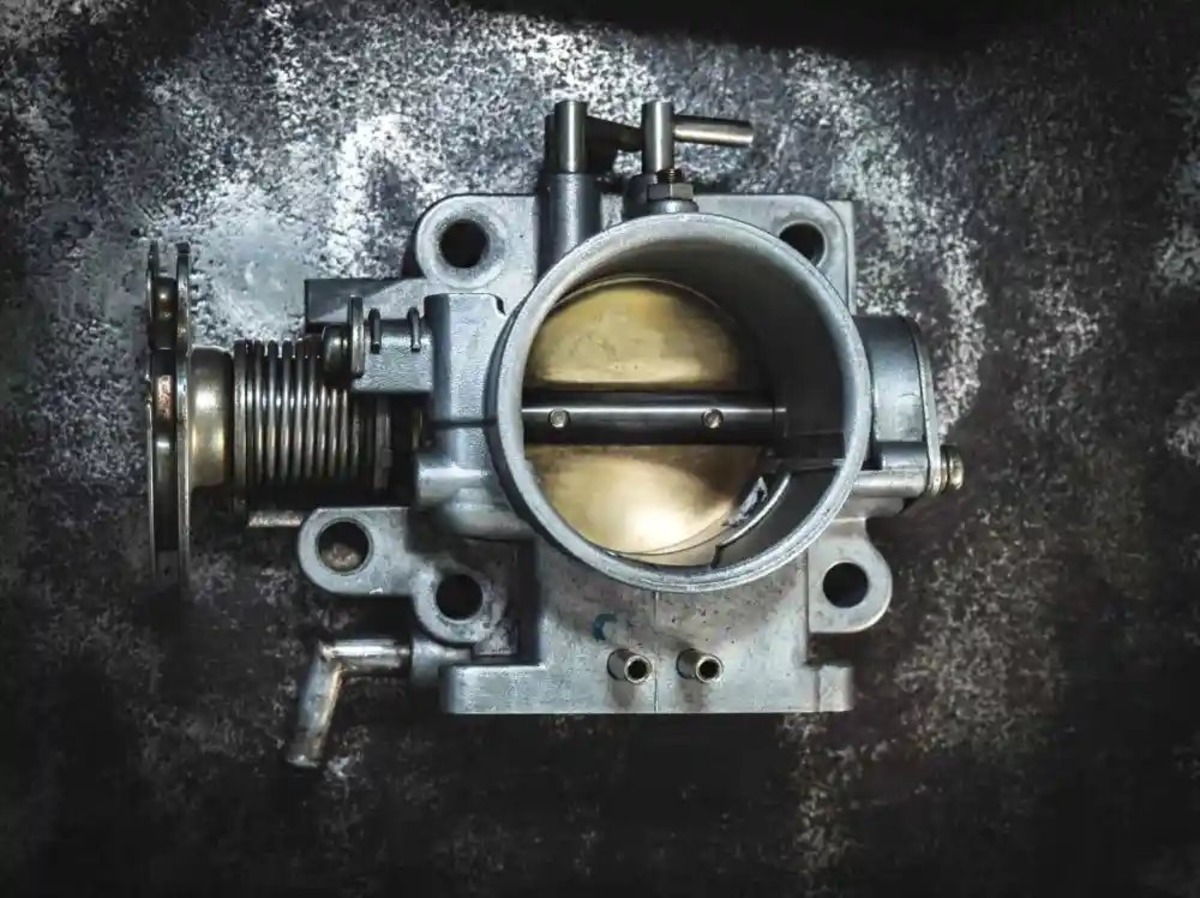

One of the common causes of Electronic Throttle Control (ETC) issues is a dirty throttle body. Over time, carbon deposits, dirt, and debris can accumulate on the throttle body, hindering its proper functioning. Cleaning the throttle body can help improve airflow and restore optimal throttle control. Here’s how to clean the throttle body:

- Gather the necessary tools: To clean the throttle body, you’ll need a clean rag or towel, throttle body cleaner, and a small brush or toothbrush.

- Locate the throttle body: The throttle body is usually located between the air intake hose and the intake manifold. Refer to your vehicle’s service manual if you’re unsure of its location.

- Disconnect the air intake hose: Loosen the clamps or screws securing the air intake hose to the throttle body and remove it carefully.

- Spray throttle body cleaner: Spray the throttle body cleaner directly onto the throttle body, focusing on the throttle plate and the surrounding areas. The cleaner will help dissolve the carbon deposits and grime.

- Gently scrub: Use the small brush or toothbrush to gently scrub the throttle plate and the inner walls of the throttle body. Be careful not to damage any delicate components.

- Wipe clean: Use the rag or towel to wipe away the loosened debris, ensuring that the throttle body is clean and free from buildup.

- Reconnect the air intake hose: Once the throttle body is clean, reattach the air intake hose and secure it with the clamps or screws.

After cleaning the throttle body, it is advisable to reset the ECU by disconnecting the battery for a few minutes or using a scan tool. This will allow the ECU to recalibrate and adapt to the clean throttle body.

Cleaning the throttle body is a simple yet effective maintenance task that can help resolve ETC issues caused by airflow restrictions. However, if the problem persists after cleaning, further troubleshooting or professional assistance may be required.

Next, we will discuss the process of replacing the throttle position sensor (TPS) if that is determined to be the cause of the ETC problem.

Replacing the Throttle Position Sensor

If cleaning the throttle body does not resolve the Electronic Throttle Control (ETC) issue, a faulty throttle position sensor (TPS) could be the culprit. The TPS is responsible for detecting and relaying the position of the throttle plate to the engine control unit (ECU). When the TPS fails, it can result in erratic throttle response and other ETC problems. Here’s how to replace the throttle position sensor:

- Obtain a replacement TPS: Ensure that you have the correct replacement TPS specific to your vehicle make and model. You can find the appropriate TPS at an auto parts store or through an authorized dealership.

- Locate the TPS: The TPS is typically situated on the throttle body, connected to the throttle shaft or throttle plate. Refer to your vehicle’s service manual or online resources for the exact location.

- Disconnect electrical connectors: Before removing the old TPS, disconnect the electrical connectors attached to it. These connectors vary in design depending on the vehicle, so consult the service manual or manufacturer instructions for guidance.

- Remove mounting screws: Use the appropriate tools, such as a wrench or screwdriver, to remove the mounting screws that secure the TPS to the throttle body. Take note of the screw positions and their sizes for reinstallation.

- Detach the old TPS: Gently detach the old TPS from the throttle body, being cautious not to damage any surrounding components. Note the orientation of the TPS for proper installation of the replacement.

- Install the new TPS: Align the replacement TPS with the mounting holes on the throttle body and secure it in place with the mounting screws. Ensure that the TPS is correctly oriented according to the previous markings.

- Reconnect electrical connectors: Attach the electrical connectors to the new TPS, ensuring a secure connection. Double-check that the connectors are firmly seated and free from any damages.

Once the new TPS is installed and all connections are secure, start the vehicle and test the throttle response. If the throttle control problems have been resolved, the replacement TPS was successful. However, if the issues persist, further diagnosis or professional assistance may be required.

Now, let’s move on to the next section, where we will discuss testing the accelerator pedal position sensor (APP) to address ETC issues.

Testing the Accelerator Pedal Position Sensor

If the throttle control problems persist even after cleaning the throttle body and replacing the throttle position sensor (TPS), it’s essential to investigate the accelerator pedal position sensor (APP). The APP sensor detects the position of the accelerator pedal and relays this information to the engine control unit (ECU). A faulty APP sensor can result in unresponsive or erratic throttle control. Here’s how to test the accelerator pedal position sensor:

- Ensure safety precautions: Before starting the testing process, ensure that the vehicle is parked on a level surface and the engine is turned off. Apply the parking brake to prevent any accidental movement.

- Locate the accelerator pedal position sensor: The APP sensor is typically located on or near the accelerator pedal assembly. Refer to your vehicle’s service manual or consult online resources for specific details.

- Check the sensor connections: Inspect the electrical connections to the APP sensor, ensuring that they are securely attached and free from any signs of damage or corrosion. Loose or damaged connections can affect the sensor’s performance.

- Perform a visual inspection: Look for any physical damages or misalignments on the accelerator pedal assembly and the APP sensor. Any visible issues may indicate a faulty sensor that requires replacement.

- Use a multimeter for testing: Set a digital multimeter to the appropriate voltage or resistance range and connect the positive (red) probe to the signal wire of the APP sensor. Ground the negative (black) probe to a suitable grounding point.

- Monitor the multimeter readings: With the ignition turned on but the engine off, gradually press and release the accelerator pedal while observing the multimeter readings. The voltage or resistance values should vary smoothly and consistently as you press and release the pedal.

- Compare readings to specifications: Consult your vehicle’s service manual to obtain the specific voltage or resistance range that corresponds to different pedal positions. Compare the multimeter readings to these specifications to determine if the APP sensor is functioning within the acceptable range.

If the multimeter readings do not align with the specified range or there is no change in the readings as you operate the accelerator pedal, it indicates a faulty accelerator pedal position sensor. In such cases, replacing the APP sensor is necessary to restore proper throttle control.

If you are unsure about performing the testing yourself or if the APP sensor replacement does not resolve the throttle control issues, it is recommended to seek professional assistance for a more accurate diagnosis and effective resolution.

Next, we will explore the importance of inspecting the wiring and connectors in the Electronic Throttle Control (ETC) system to address connectivity issues.

Inspecting the Wiring and Connectors

When encountering Electronic Throttle Control (ETC) problems, it’s crucial to examine the wiring and connectors associated with the throttle control system. Faulty or damaged wiring, as well as loose or corroded connectors, can disrupt the communication between the components and the engine control unit (ECU), leading to various throttle control issues. Here’s how to inspect the wiring and connectors:

- Perform a visual inspection: Begin by visually inspecting the wiring harnesses and connectors associated with the throttle control system. Look for any signs of frayed or damaged wires, loose connections, or corrosion. Pay close attention to areas where the wiring is exposed to heat or potential damage.

- Check for physical damages: Gently tug on the wiring harnesses to ensure they are securely attached to their corresponding components. If any wires feel loose or appear damaged, it may indicate a wiring problem that needs attention.

- Inspect the connectors: Examine the connectors, looking for signs of corrosion, bent pins, or loose contacts. Corroded or dirty connectors can hinder proper electrical connections, causing throttle control problems.

- Clean corroded connectors: If you spot corrosion on the connectors, use a suitable electrical contact cleaner or rubbing alcohol and a soft brush to clean the contacts. Ensure the connectors are completely dry before reattaching them. Additionally, consider applying dielectric grease to prevent future corrosion.

- Perform continuity tests: Using a digital multimeter, perform continuity tests on the wiring harnesses and connectors. Follow the vehicle’s service manual or wiring diagrams to identify the appropriate pins and perform the tests. Lack of continuity or significant resistance can indicate a wiring issue that needs to be addressed.

- Repair or replace damaged wiring: If you identify any damaged or faulty wires during the inspection, it is crucial to repair or replace them. Use appropriate wiring repair techniques, such as soldering or using automotive-grade wire connectors. Ensure proper insulation and secure any repaired or replaced wires securely away from moving components.

- Ensure secured connections: After completing the inspection and any necessary repairs, firmly reconnect the wiring harnesses to their respective connectors. Ensure that all connections are properly seated and secure.

Thoroughly inspecting the wiring and connectors can help identify and rectify any issues that may be causing poor connectivity in the ETC system. By addressing these problems, the communication between the components and the ECU can be restored, allowing for more reliable throttle control.

If the throttle control issues persist after inspecting and repairing the wiring and connectors, it is recommended to seek the assistance of a professional technician who can conduct advanced diagnostics or further investigation.

Next, we will discuss the importance of calibrating the Electronic Throttle Control (ETC) system to ensure optimal performance.

Calibrating the Electronic Throttle Control System

Calibrating the Electronic Throttle Control (ETC) system is an important step in ensuring optimal performance and responsiveness. Over time, factors such as wear and tear, component replacements, or diagnostic procedures may require recalibration. Proper calibration helps synchronize the throttle control components and the engine control unit (ECU), resulting in more accurate throttle response. Here’s how to calibrate the ETC system:

- Ensure safety precautions: Before beginning the calibration process, park the vehicle on a level surface and engage the parking brake. Make sure the engine is turned off.

- Consult the vehicle’s service manual: Each vehicle may have specific instructions and procedures for calibrating the ETC system. Refer to the vehicle’s service manual or online resources to obtain the correct calibration procedure for your make and model.

- Reset the ECU: Before calibrating, it may be necessary to reset the ECU by disconnecting the battery for a few minutes or using a scan tool. This clears any previous adaptations and allows for a fresh calibration process.

- Follow the calibration procedure: Depending on the vehicle, the calibration process may involve cycling the ignition key, pressing certain buttons or pedals in a specific sequence, or using a scan tool to initiate the calibration mode.

- Perform the calibration steps: Carefully follow the instructions outlined in the calibration procedure. This may involve actions such as pressing and releasing the accelerator pedal, holding specific buttons, or following prompts on the scan tool.

- Monitor for completion: During the calibration process, monitor for any specific indications or prompts that confirm the calibration is complete. Follow any additional instructions provided in the calibration procedure.

- Test throttle response: After completing the calibration, start the engine and test the throttle response. Confirm that the acceleration is smooth and consistent, without any hesitation or erratic behavior.

Calibrating the ETC system is an essential step in maintaining optimal throttle control. It helps ensure that the throttle components and the ECU are working in sync, maximizing performance and responsiveness. However, it’s important to note that not all vehicles require user-initiated calibration. Some vehicles have self-calibrating systems that automatically adjust as needed. Therefore, consulting the vehicle’s service manual is vital to determine the correct calibration procedure.

If the throttle control issues persist after calibration or if you are unsure about performing the calibration yourself, it’s recommended to seek professional assistance. Trained technicians have the knowledge and tools to perform advanced diagnostics and calibration to resolve any persistent ETC problems.

In the final section, we will discuss when it is appropriate to seek professional help for Electronic Throttle Control (ETC) problems.

When to Seek Professional Help

While many Electronic Throttle Control (ETC) issues can be resolved through basic troubleshooting and maintenance, there may come a time when it is necessary to seek professional help. Professional assistance can provide specialized knowledge, advanced diagnostic equipment, and expert solutions to more complex throttle control problems. Here are some situations when it is recommended to seek professional help:

- Persistent throttle control issues: If you’ve attempted basic troubleshooting steps, such as cleaning the throttle body, replacing sensors, or inspecting wiring, and the throttle control problems persist, seeking professional assistance is advisable. Trained technicians have the expertise to diagnose and resolve more complex issues that may require specialized tools or knowledge.

- Technical expertise required: Throttle control systems can be intricate, involving complex electronic components and computer systems. If you’re unfamiliar with these systems or lack the necessary technical knowledge, it’s best to consult a professional. They can perform in-depth diagnostics, identify the root cause of the problem, and apply appropriate solutions.

- Manufacturer-specific issues: Certain ETC problems may be specific to a particular vehicle make or model. Authorized dealerships or service centers often have access to manufacturer-specific diagnostic tools, software, and technical support. If you suspect the issue may be related to manufacturer-specific systems or software, it’s advisable to seek assistance from an authorized service provider.

- Warranty and recalls: If your vehicle is under warranty, it’s important to consult the authorized dealership or service center for any ETC-related issues. They can determine if the problem falls under warranty coverage and provide the appropriate repairs or replacements. Additionally, if there is a known recall related to the ETC system, professional help is necessary to ensure compliance and rectification.

- Safety concerns: If you experience sudden and severe throttle control problems that impact the safe operation of your vehicle, seeking immediate professional assistance is crucial. Safety should always be a top priority, and professionals can address the issue promptly and efficiently, minimizing the risk of accidents or further damage.

It’s important to remember that every vehicle and situation is unique. If you’re uncertain or uncomfortable in any way while performing troubleshooting or repairs, it’s best to consult a professional. Professional technicians have the necessary training and expertise to diagnose, repair, and maintain the Electronic Throttle Control system effectively.

By seeking professional help when needed, you can ensure the proper functioning of your vehicle’s throttle control system and maintain its performance, reliability, and safety.