Electric Power Steering (EPS) Systems

Electric Power Steering (EPS) systems have revolutionized the automotive industry by replacing traditional hydraulic power steering systems. EPS systems are designed to provide a smoother and more efficient steering experience for drivers.

So, how does EPS work? Unlike hydraulic systems that rely on fluid pressure, EPS systems utilize an electric motor to assist with steering. Sensors constantly monitor the driver’s input and provide feedback to the electric motor, which then applies the necessary force to help turn the wheels.

One of the key benefits of EPS is its improved fuel efficiency. Since the electric motor only activates when assistance is needed, it consumes less energy compared to hydraulic systems that constantly rely on the engine-driven power steering pump. This not only reduces fuel consumption but also decreases emissions.

In addition to improved fuel efficiency, EPS also offers several other advantages. First and foremost, it provides enhanced maneuverability at lower speeds, making parking and navigating tight spaces much easier. The steering effort is also adjustable, allowing drivers to customize the level of assistance according to their preference and driving conditions.

However, like any technology, EPS also has its limitations. One of the main concerns is the loss of power steering assistance in case of a system failure or electrical malfunction. In such situations, drivers may experience increased effort required to steer the vehicle, especially at lower speeds.

Overall, EPS systems have become increasingly popular due to their efficiency, improved maneuverability, and customizable settings. It is important for drivers to understand the capabilities and limitations of EPS systems to ensure safe and comfortable driving experiences.

How Does EPS Work?

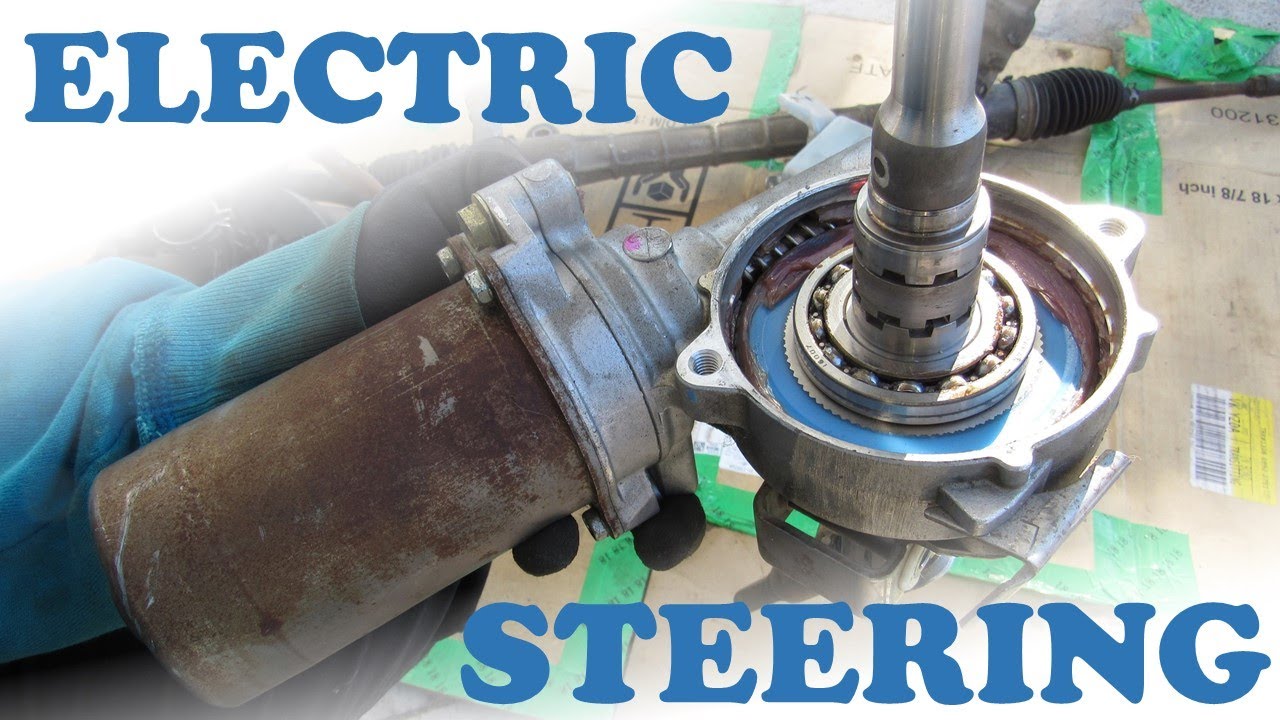

Electric Power Steering (EPS) systems utilize advanced technology to assist drivers in steering their vehicles. The system consists of three main components: a steering torque sensor, an electronic control unit (ECU), and an electric power assist motor.

When a driver turns the steering wheel, the steering torque sensor detects the amount of force applied. This information is then sent to the ECU, which calculates the necessary level of assistance needed based on the vehicle’s speed, steering angle, and other factors.

The ECU then sends signals to the electric power assist motor, directing it to apply the appropriate amount of power assistance. The motor is connected to the steering gear and assists in turning the wheels, reducing the effort required by the driver.

EPS systems are designed to provide variable assistance, meaning that the level of assistance changes depending on the driving conditions. At higher speeds, the system may reduce the level of assistance to provide better stability and control. At lower speeds, such as during parking or maneuvering, the system increases assistance to make steering easier.

One of the key features of EPS systems is their ability to adapt to different driving situations. For example, some EPS systems have a speed-sensitive feature that adjusts the level of assistance based on the vehicle’s speed. This ensures a comfortable steering experience at all speeds.

Another important aspect of EPS is its integration with other vehicle systems. Modern EPS systems are often linked to electronic stability control (ESC) and other safety features. This integration allows the system to provide additional assistance in emergency situations, such as during sudden maneuvers or when the vehicle detects instability.

Overall, EPS systems utilize a combination of sensors, control units, and electric motors to provide drivers with improved steering control and comfort. By continuously monitoring the driver’s input and adjusting the level of assistance, EPS systems enhance the overall driving experience and safety.

Benefits of EPS

Electric Power Steering (EPS) systems offer several advantages over traditional hydraulic power steering systems. These benefits contribute to a more efficient, comfortable, and safer driving experience. Here are some of the key benefits of EPS:

1. Improved Fuel Efficiency: EPS systems are more energy-efficient than hydraulic systems. Since the electric motor only activates when assistance is needed, it consumes less energy, resulting in improved fuel efficiency and reduced emissions. This is especially beneficial for fuel economy-conscious drivers.

2. Enhanced Maneuverability: EPS provides enhanced maneuverability, particularly at lower speeds. The electric motor’s assistance makes it easier to steer during parking and tight maneuvers, reducing the effort required by the driver. This is helpful for urban driving where parking spaces and crowded streets can present challenges.

3. Adjustable Steering Effort: EPS systems offer customizable steering effort. Drivers can adjust the level of assistance according to their preference or driving conditions. This flexibility allows for a more personalized steering experience, ensuring optimal comfort and control on various road surfaces.

4. Seamless Integration with Vehicle Systems: EPS systems are often integrated with other vehicle systems, such as electronic stability control (ESC) and advanced driver assistance systems (ADAS). This integration allows EPS to work in harmony with these systems, providing enhanced safety and stability during emergency maneuvers or challenging driving conditions.

5. Reduced Maintenance: Compared to hydraulic power steering systems, EPS systems require less maintenance. There is no need for regular fluid changes, and there are fewer components that can wear out or leak. This can result in cost savings and less downtime for vehicle maintenance.

6. Weight Savings: EPS systems are typically lighter than hydraulic systems, contributing to overall weight reduction in the vehicle. This weight reduction can have a positive impact on fuel efficiency, handling, and performance.

7. Improved Driver Feedback: EPS systems are designed to provide more precise and responsive steering feedback to the driver. This allows for better vehicle control and a more connected driving experience, especially during dynamic driving situations or on challenging road surfaces.

Different Types of EPS

There are several different types of Electric Power Steering (EPS) systems, each with its own unique characteristics and implementations. Here are some of the most common types:

1. Column-Assist EPS: This type of EPS system is one of the earliest versions and is widely used in many vehicles. In this system, the electric motor is mounted directly on the steering column, assisting the driver’s steering inputs. Column-assist EPS provides a compact design, making it easier to integrate into various vehicle platforms.

2. Rack-Assist EPS: In rack-assist EPS systems, the electric motor is located at the steering rack instead of the steering column. This design allows for more precise control and better feedback to the driver. Rack-assist EPS is known for providing a more direct and responsive steering feel, enhancing the overall driving experience.

3. Pinion-Assist EPS: Pinion-assist EPS is similar to rack-assist EPS, but the electric motor is located at the steering pinion instead of the rack. This type of EPS system offers similar benefits in terms of better control and feedback. Pinion-assist EPS is commonly used in vehicles with limited space in the engine compartment.

4. Dual-Pinion EPS: Dual-pinion EPS systems utilize two motors instead of one. This design allows for enhanced redundancy and greater flexibility in terms of control and customization. Dual-pinion EPS systems are often used in larger vehicles or high-performance models, where additional power and precision are desirable.

5. Column-Drive EPS: In column-drive EPS systems, the electric motor is integrated into the steering column and directly drives the column’s rotation. This design eliminates the need for additional mechanical components such as gears or belts. Column-drive EPS provides a simplified and compact solution, particularly in electric vehicles where space optimization is crucial.

6. Torque-Assist EPS: Torque-assist EPS systems focus on adjusting the level of assistance based on the torque applied by the driver. These systems analyze the driver’s steering inputs, vehicle speed, and other factors to fine-tune the assist torque for optimal control and stability. Torque-assist EPS offers improved responsiveness and adaptability in various driving conditions.

It’s important to note that different vehicle manufacturers may implement these EPS systems with variations and additional features tailored to their specific models. The type of EPS used in a vehicle can significantly impact the driving experience, including steering feel, responsiveness, and adaptability to different road conditions.

Hydraulic Electric Power Steering (HEPS)

Hydraulic Electric Power Steering (HEPS) is a hybrid steering system that combines elements of both traditional hydraulic power steering and electric power steering. HEPS systems aim to provide the benefits of both systems while minimizing their limitations.

In a HEPS system, an electric motor is used to assist the traditional hydraulic power steering system. The electric motor helps to reduce the workload on the hydraulic pump, resulting in improved fuel efficiency compared to conventional hydraulic power steering.

How does HEPS work? When the driver turns the steering wheel, sensors detect the input and send signals to the control unit. The control unit then adjusts the assistance provided by the electric motor, which in turn assists the hydraulic power steering system.

One of the key advantages of HEPS is its ability to vary the level of assistance based on driving conditions. This means that the system can provide more assistance at low speeds, such as during parking or maneuvering, and reduce assistance at higher speeds for better stability.

HEPS also offers a smoother and more responsive steering feel compared to traditional hydraulic systems. The integration of the electric motor allows for precise control and adjustment of the steering assistance, resulting in improved handling and maneuverability.

Another benefit of HEPS is its compatibility with existing hydraulic power steering systems. Retrofitting a vehicle with HEPS is often easier and more cost-effective than completely replacing the hydraulic system with electric power steering.

However, there are some limitations to consider with HEPS. One drawback is the dependence on hydraulic components, which can be susceptible to leaks or failures over time. Additionally, HEPS systems may not achieve the same level of energy efficiency as fully electric power steering systems.

Despite these limitations, HEPS offers a balanced solution for drivers who seek the advantages of both hydraulic and electric power steering. It combines the smoothness and responsiveness of electric power steering with the familiarity and reliability of hydraulic systems. HEPS is a viable option for vehicles where the complete transition to electric power steering may not be feasible or practical.

How Does HEPS Work?

Hydraulic Electric Power Steering (HEPS) combines elements of both hydraulic power steering and electric power steering to provide a balanced and efficient steering system. HEPS works by utilizing an electric motor to assist the hydraulic power steering system, improving fuel efficiency and overall steering performance.

When the driver turns the steering wheel, sensors detect the input and send signals to the control unit. The control unit analyzes the driver’s input, vehicle speed, and other factors to determine the appropriate level of assistance required.

The control unit then sends instructions to the electric motor, which delivers additional power to assist the hydraulic power steering system. This assistance reduces the workload on the hydraulic pump, resulting in improved efficiency compared to conventional hydraulic power steering.

The hydraulic power steering system, consisting of a power steering pump, hydraulic fluid, and steering gear, is responsible for transmitting the force from the steering wheel to the wheels. The assistance provided by the electric motor enhances the hydraulic system’s capabilities, making steering smoother and easier for the driver.

HEPS systems also have the ability to vary the level of assistance based on driving conditions. At low speeds, such as during parking or maneuvering, the system provides higher assistance to make steering effortless. At higher speeds, the assistance is reduced to enhance stability and driver control.

HEPS systems aim to provide a seamless integration of electric and hydraulic components. While the electric motor assists the hydraulic system, the hydraulic components remain responsible for transmitting the steering force. This combination allows for a more refined and precise steering feel compared to traditional hydraulic systems.

It’s important to note that each vehicle manufacturer may implement HEPS systems differently, resulting in variations in performance and features. Advanced HEPS systems may include additional features such as speed-sensitive assistance, customizable steering modes, and integration with other vehicle systems like electronic stability control.

Overall, HEPS provides a hybrid solution that combines the benefits of electric power steering and hydraulic power steering. By integrating an electric motor to assist the hydraulic system, HEPS offers improved fuel efficiency, enhanced steering performance, and a smoother driving experience.

Advantages and Disadvantages of HEPS

Hydraulic Electric Power Steering (HEPS) systems offer a combination of benefits and drawbacks when compared to traditional hydraulic power steering systems or fully electric power steering systems. Understanding the advantages and disadvantages of HEPS can help drivers make informed decisions. Here’s an overview:

Advantages of HEPS:

1. Improved Fuel Efficiency: HEPS systems provide better fuel efficiency compared to conventional hydraulic power steering systems. By utilizing an electric motor to assist the hydraulic system, HEPS reduces the workload on the hydraulic pump, resulting in reduced energy consumption and improved overall fuel economy.

2. Enhanced Steering Performance: HEPS combines the smoothness and responsiveness of electric power steering with the familiarity and reliability of hydraulic systems. The electric motor assistance results in a more refined and precise steering feel, enhancing the driver’s control and confidence on the road.

3. Adaptability to Driving Conditions: HEPS systems can vary the level of assistance based on driving conditions. They provide higher assistance at low speeds, making parking and maneuvering easier. At higher speeds, the assistance is reduced to enhance stability and driver control.

4. Compatibility with Existing Hydraulic Systems: Retrofitting a vehicle with HEPS is often simpler and more cost-effective compared to a complete transition to fully electric power steering. HEPS can be integrated into the existing hydraulic power steering system, making it a viable option for vehicles where a complete overhaul is not feasible or practical.

Disadvantages of HEPS:

1. Dependence on Hydraulic Components: Although HEPS systems provide assistance through an electric motor, they still rely on hydraulic components such as power steering pumps and steering gears. This dependence can make HEPS systems vulnerable to issues like leaks or failures, which may require repairs or maintenance.

2. Potential Energy Efficiency Limitations: While HEPS offers improved fuel efficiency compared to traditional hydraulic systems, it may not achieve the same level of efficiency as fully electric power steering systems. The need to power both the hydraulic and electric systems can still result in some energy consumption.

3. Limited Customization: HEPS systems may not offer the same level of customization as fully electric power steering systems. Some fully electric systems allow drivers to adjust various parameters like steering effort or responsiveness, while HEPS systems may have more limited customization options.

4. Complexity and Potential Maintenance: HEPS introduces additional complexity with the integration of electric and hydraulic components, which can potentially increase maintenance requirements and costs. Regular inspections and maintenance of both electric and hydraulic components may be necessary to ensure optimal performance and longevity of the system.

Electric Power Steering (EPS)

Electric Power Steering (EPS) has become increasingly popular in the automotive industry due to its numerous advantages over traditional hydraulic power steering systems. EPS utilizes an electric motor to provide assistance in steering, resulting in improved efficiency, maneuverability, and driver comfort.

So, how does EPS work? EPS systems consist of three main components: a steering torque sensor, an electronic control unit (ECU), and an electric power assist motor. The torque sensor detects the amount of force applied by the driver, and the ECU calculates the required level of assistance based on various parameters.

The ECU then controls the electric motor, which applies force to the steering mechanism, reducing the effort required by the driver. This enables precise and effortless steering, especially at lower speeds or during parking and maneuvering situations.

EPS offers several advantages compared to hydraulic power steering systems. One of the key benefits is improved fuel efficiency. Unlike hydraulic systems that constantly rely on the engine-driven power steering pump, EPS systems only activate the electric motor when assistance is needed. This results in reduced energy consumption and lower fuel consumption.

Another advantage of EPS is its enhanced maneuverability. The electric motor’s assistance makes it easier to steer, especially in tight spaces and urban environments. This improves the overall driving experience and reduces driver fatigue.

EPS also offers the flexibility of adjustable steering effort. Drivers can customize the level of assistance according to their preferences and driving conditions, providing a personalized steering experience. This adaptability allows drivers to have full control over their vehicle’s handling and responsiveness.

While EPS systems offer numerous benefits, they do have some limitations. One concern is the loss of power steering assistance in case of a system failure or electrical malfunction. When this occurs, manual steering becomes more difficult, particularly at lower speeds.

Despite this limitation, EPS technology continues to evolve, incorporating advancements such as speed-sensitive assistance and integration with other vehicle systems. EPS systems are commonly integrated with electronic stability control (ESC) and advanced driver assistance systems (ADAS), enhancing safety and overall driving performance.

How Does EPS Work?

Electric Power Steering (EPS) systems utilize advanced technology to assist drivers in steering their vehicles. The system consists of three main components: a steering torque sensor, an electronic control unit (ECU), and an electric power assist motor.

When a driver turns the steering wheel, the steering torque sensor detects the amount of force applied. This information is then sent to the ECU, which calculates the necessary level of assistance needed based on the vehicle’s speed, steering angle, and other factors.

The ECU then sends signals to the electric power assist motor, directing it to apply the appropriate amount of power assistance. The motor is connected to the steering gear and assists in turning the wheels, reducing the effort required by the driver.

EPS systems are designed to provide variable assistance, meaning that the level of assistance changes depending on the driving conditions. At higher speeds, the system may reduce the level of assistance to provide better stability and control. At lower speeds, such as during parking or maneuvering, the system increases assistance to make steering easier.

One of the key features of EPS systems is their ability to adapt to different driving situations. For example, some EPS systems have a speed-sensitive feature that adjusts the level of assistance based on the vehicle’s speed. This ensures a comfortable steering experience at all speeds.

Another important aspect of EPS is its integration with other vehicle systems. Modern EPS systems are often linked to electronic stability control (ESC) and other safety features. This integration allows the system to provide additional assistance in emergency situations, such as during sudden maneuvers or when the vehicle detects instability.

EPS systems are known for their precision and responsiveness. The electric motor can provide immediate assistance, offering a more direct connection between the driver and the vehicle’s steering response. This enhances the overall driving experience and allows for greater control and maneuverability.

EPS technology continues to evolve, with newer systems incorporating advanced features such as lane-keeping assist and adaptive steering. These advancements further enhance safety, convenience, and driver comfort.

Overall, EPS systems utilize a combination of sensors, control units, and electric motors to provide drivers with improved steering control and comfort. By continuously monitoring the driver’s input and adjusting the level of assistance, EPS systems enhance the overall driving experience and safety.

Advantages and Disadvantages of EPS

Electric Power Steering (EPS) systems have revolutionized the automotive industry, offering numerous advantages over traditional hydraulic power steering systems. However, they also have their limitations. Understanding the advantages and disadvantages of EPS can help drivers make informed decisions. Here’s an overview:

Advantages of EPS:

1. Improved Fuel Efficiency: EPS systems are more energy-efficient compared to hydraulic power steering systems. Since the electric motor only activates when assistance is needed, it consumes less energy, resulting in improved fuel efficiency and reduced emissions. This is especially beneficial for fuel economy-conscious drivers.

2. Enhanced Maneuverability: EPS provides enhanced maneuverability, particularly at lower speeds. The electric motor’s assistance makes it easier to steer during parking and tight maneuvers, reducing the effort required by the driver. This is helpful for urban driving where parking spaces and crowded streets can present challenges.

3. Adjustable Steering Effort: EPS systems offer customizable steering effort. Drivers can adjust the level of assistance according to their preference or driving conditions. This flexibility allows for a more personalized steering experience, ensuring optimal comfort and control on various road surfaces.

4. Quick and Responsive Steering: EPS systems are known for their precise and responsive steering capabilities. The electric motor provides immediate assistance, offering a direct connection between the driver’s inputs and the vehicle’s steering response. This enhances the overall driving experience, especially in dynamic driving situations.

5. Compatibility with Advanced Safety Features: EPS systems can be seamlessly integrated with other advanced safety features such as electronic stability control (ESC), lane-keeping assist, and collision avoidance systems. This integration allows for enhanced safety and maneuverability in various driving conditions.

Disadvantages of EPS:

1. Loss of Power Assistance in System Failure: One of the main concerns with EPS systems is the loss of power assistance in case of a system failure or electrical malfunction. This can happen if there is a disruption in the electrical supply or a fault in the system. In such situations, drivers may experience increased effort required to steer the vehicle, especially at lower speeds.

2. Reliance on Electrical Components: EPS systems rely heavily on electrical components, including sensors, control units, and motors. The proper functioning of these components is crucial for the system’s performance. Electrical malfunctions or failures can lead to a loss of steering assistance or inaccurate steering inputs.

3. Potential Disconnection from Road Feel: Some drivers may feel that EPS systems can disconnect them from the road feel compared to hydraulic power steering systems. As EPS relies on sensors and motors, the natural feedback from the road to the steering wheel may be reduced.

4. Higher Cost of Repairs: In the event of component failure or malfunction, repairs or replacements of EPS components can be more expensive compared to hydraulic power steering systems. The complexity and integration of electrical and electronic components contribute to higher repair costs.

Despite the limitations, EPS continues to evolve and improve, offering increased efficiency, safety, and driving comfort. It’s essential for drivers to understand the capabilities and limitations of EPS systems to ensure safe and enjoyable driving experiences.

Steer-by-Wire (SBW) Systems

Steer-by-Wire (SBW) systems represent an innovative steering technology that eliminates the mechanical connection between the steering wheel and the wheels. Instead of using mechanical linkage, SBW systems utilize electrical signals to control the vehicle’s steering. This advanced technology offers unique advantages and capabilities over traditional steering systems.

In a SBW system, the steering wheel is replaced by an electronic control unit (ECU) that receives input from the driver’s steering movements. The ECU then sends electrical signals to actuators located at each wheel or in the steering system, which directly controls the steering angle without the need for mechanical linkage.

One of the primary advantages of SBW systems is the flexibility they offer in steering customization. These systems can provide drivers with the option to adjust steering effort, steering feel, and even the steering ratio, according to their preferences and driving conditions. This level of customization can enhance the driving experience and improve safety.

Another significant advantage of SBW systems is their potential to enable advanced driver assistance features and autonomous driving capabilities. Since SBW systems are entirely electronic and not reliant on physical connections, they can easily integrate with other vehicle systems, such as electronic stability control and adaptive cruise control. This integration allows for improved vehicle control, stability, and potentially smoother transitions between manual and autonomous driving modes.

SBW systems can also contribute to weight reduction in vehicles. Without the need for heavy mechanical components like steering columns, shafts, and linkages, vehicles equipped with SBW systems can shed weight. This weight reduction can improve overall fuel efficiency and performance.

However, SBW systems also come with unique challenges and potential disadvantages. One significant concern is related to system reliability and redundancy. Since SBW relies entirely on electronic signals, any malfunction or failure in the control electronics or power supply can result in a complete loss of steering control. Ensuring robust backup systems and redundancy is crucial to address these safety concerns.

Another potential drawback is the potential lack of direct mechanical feedback and feel that drivers may be accustomed to in traditional steering systems. SBW systems require artificial feedback mechanisms to replicate the feel of the road and the vehicle’s behavior. While automakers strive to provide accurate and intuitive feedback, the absence of direct mechanical connections can impact the driver’s perception and response.

The adoption of SBW systems in vehicles is still relatively limited and primarily present in high-end luxury vehicles and concept cars. The technology continues to evolve, and ongoing research and development aim to address the challenges associated with implementing SBW systems in more widespread applications.

What is Steer-by-Wire?

Steer-by-Wire (SBW) is an advanced steering technology that completely replaces the traditional mechanical linkage between the steering wheel and the wheels. Instead of using physical connections, SBW systems employ electrical signals to control the steering angle and provide steering assistance. This innovative approach offers unique benefits and opens up new possibilities in vehicle design and driving experience.

In a SBW system, the steering wheel is replaced by an electronic control unit (ECU) that senses the driver’s steering input. The ECU then translates those inputs into electrical signals and transmits them to actuators, which directly control the steering mechanism without any mechanical connection.

One of the main advantages of SBW is the increased flexibility and customization it offers. Since SBW systems are entirely electronic, they can provide drivers with the ability to adjust steering effort, steering feel, and even the steering ratio according to their preferences and driving conditions. This level of customization can enhance the driving experience and improve overall safety.

SBW systems also have the potential to enable advanced driver assistance features and autonomous driving capabilities. By decoupling the steering from the mechanical system, SBW systems make it easier to integrate with other vehicle systems, such as electronic stability control and adaptive cruise control. This integration allows for improved vehicle control, stability, and potentially smoother transitions between manual and autonomous driving modes.

Another benefit of SBW is the potential for weight reduction in vehicles. Without the need for heavy mechanical components like steering columns, shafts, and linkages, vehicles equipped with SBW systems can shed weight. This weight reduction can have a positive impact on fuel efficiency, performance, and handling.

However, it’s important to note that implementing SBW systems also comes with its challenges and considerations. One significant concern is related to system reliability and redundancy. Since SBW relies entirely on electrical signals, any malfunction or failure in the control electronics or power supply can result in a complete loss of steering control. Implementing robust backup systems and redundancy measures is crucial to address these safety concerns.

Additionally, SBW systems may lack the direct mechanical feedback and feel that drivers are accustomed to in traditional steering systems. Replicating the feel of the road and the vehicle’s behavior requires artificial feedback mechanisms. While automakers strive to provide accurate and intuitive feedback, the absence of direct mechanical connections can impact the driver’s perception and response.

The adoption of SBW systems is still relatively limited and primarily found in high-end luxury vehicles and concept cars. However, ongoing research and development aim to overcome the challenges and pave the way for wider implementation of SBW technology in the future.

Advantages and Disadvantages of SBW Systems

Steer-by-Wire (SBW) systems offer a revolutionary approach to steering technology, replacing mechanical connections with electronic signals. These systems come with unique advantages and disadvantages that impact vehicle performance and driver experience. Understanding the advantages and disadvantages of SBW systems is crucial for evaluating their potential in modern vehicles. Here’s an overview:

Advantages of SBW Systems:

1. Design Flexibility: SBW systems provide design flexibility as they eliminate the need for traditional mechanical components like steering columns, shafts, and linkages. This opens up possibilities for more streamlined vehicle designs, improved packaging efficiency, and enhanced interior space utilization.

2. Customizable Steering Characteristics: SBW systems offer the ability to customize steering characteristics such as effort, feel, and steering ratio. Drivers can tailor the steering response to their preferences or adapt it for different driving conditions, enhancing the overall driving experience and driver confidence.

3. Potential for Advanced Driver Assistance Systems: SBW systems facilitate seamless integration with advanced driver assistance systems (ADAS), adaptive cruise control, and autonomous driving technologies. The absence of mechanical linkage simplifies integration, enabling more precise and dynamic control over the steering system in coordination with other vehicle systems.

4. Improved Steering Response and Stability: SBW systems can provide faster and more precise steering responses compared to traditional mechanical systems. The elimination of mechanical play and the ability to adjust steering characteristics contribute to improved stability, especially in dynamic driving situations and emergency maneuvers.

Disadvantages of SBW Systems:

1. Reliability and Safety Concerns: SBW systems heavily rely on electrical components and control systems. Any malfunction or failure in the control electronics, sensors, or power supply can lead to a complete loss of steering control. Ensuring robust redundancy, backup systems, and fail-safe mechanisms are crucial to address safety concerns.

2. Artificial Feedback and Feel: SBW systems lack the direct mechanical feedback and feel of traditional steering systems. Replicating the feel of the road and the vehicle’s behavior requires artificial feedback mechanisms. While efforts are made to provide accurate and intuitive feedback, the absence of direct mechanical connections can impact the driver’s perception and response.

3. Dependency on Electrical Systems: SBW systems heavily depend on electrical components and precise electronic controls. This creates additional complexity, making the system susceptible to electrical malfunctions, electromagnetic interference, and potential cyber threats, demanding robust and secure electrical architectures.

4. Higher Cost and Maintenance Complexity: SBW systems can be more expensive to design, develop, and manufacture compared to traditional steering systems. The complexity of electronic components and the need for redundancy increases costs and maintenance complexity, potentially requiring specialized expertise and higher repair or replacement costs.

As SBW technology continues to evolve, addressing these concerns and refining system performance will be crucial for widespread adoption, ensuring robust reliability, safety, and an enhanced driving experience.

Comparison: HEPS vs. EPS vs. SBW

When it comes to steering technology, three main options are Hydraulic Electric Power Steering (HEPS), Electric Power Steering (EPS), and Steer-by-Wire (SBW) systems. Each has its own unique characteristics and advantages. Let’s compare these three systems based on several key factors:

1. Steering Feel and Responsiveness: HEPS systems provide a hydraulic-assisted feel, offering a more traditional and familiar steering experience. EPS systems offer precise and responsive steering due to their electric motor assistance. SBW systems provide customizable steering characteristics, allowing for greater flexibility in terms of both effort and feel.

2. Energy Efficiency: HEPS systems, with their use of electric motor assistance alongside hydraulic power, offer improved fuel efficiency compared to traditional hydraulic systems. EPS systems are even more energy efficient as the electric motor only activates when assistance is needed. SBW systems can also contribute to energy efficiency by reducing weight and allowing for more efficient integration with other vehicle systems.

3. Maneuverability and Parking: EPS systems excel in low-speed maneuverability, making parking and tight turns easier. The electric motor assistance provides a lighter steering feel, requiring less effort from the driver. SBW systems can also offer customizable assistance, enhancing maneuverability and parking capabilities even further.

4. Safety and Redundancy: HEPS and EPS systems rely on mechanical components, making them less dependent on electrical systems. This can provide a level of redundancy and safety in case of electrical malfunctions. In contrast, SBW systems, which are fully electronic, require robust backup systems and redundancy measures to ensure steering control in case of system failures.

5. Flexibility and Integration: While HEPS and EPS systems are easier to integrate into existing vehicles with hydraulic systems, SBW systems offer the most design flexibility. SBW eliminates the need for mechanical linkages, allowing for more streamlined vehicle designs, improved packaging efficiency, and easier integration with advanced driver assistance systems and autonomous driving features.

6. Maintenance and Cost: HEPS systems may require more maintenance due to the presence of hydraulic components that can develop leaks or require regular fluid changes. EPS systems, on the other hand, require minimal maintenance. SBW systems, being the most advanced and complex, can be more expensive to develop, manufacture, and maintain due to the need for precise electronic controls and redundancy measures.

Ultimately, the choice between HEPS, EPS, and SBW depends on various factors such as vehicle type, manufacturer preferences, and driver requirements. HEPS and EPS systems strike a balance between tradition and innovation, while SBW systems offer cutting-edge technology and customization. As technology continues to evolve, further advancements in steering systems can be expected, enhancing safety, efficiency, and driving experience.

Which Steering System is Right for You?

Choosing the right steering system depends on various factors, including personal preferences, driving needs, and the type of vehicle. Each steering system – Hydraulic Electric Power Steering (HEPS), Electric Power Steering (EPS), and Steer-by-Wire (SBW) – offers unique advantages and considerations. Here are some factors to consider when selecting a steering system:

1. Driving Experience: If you prefer a traditional steering feel with added efficiency, HEPS systems may be suitable. This system offers a familiar hydraulic-assisted feel with improved fuel efficiency. For a more responsive and precise steering experience, EPS systems provide electric motor assistance that enhances maneuverability and control. If customization and advanced features are important to you, SBW systems offer adjustable steering characteristics and integration with advanced driver assistance systems.

2. Fuel Efficiency: If fuel efficiency is a top priority, EPS and HEPS systems outperform traditional hydraulic systems. EPS systems consume less energy by activating the electric motor only when assistance is needed. HEPS systems combine hydraulic and electric power for improved fuel efficiency compared to traditional hydraulic systems.

3. Maneuverability: If you often navigate tight spaces or frequently engage in low-speed maneuvering, EPS and SBW systems excel. The lighter steering effort provided by EPS systems makes parking and tight turns easier. SBW systems allow for customizable steering assistance, enhancing maneuverability in various driving conditions.

4. Integration and Future-Proofing: If you desire flexibility and integration with advanced technologies, SBW systems offer the greatest potential. Their electronic nature allows for easier integration with advanced driver assistance systems and autonomous driving features. HEPS and EPS systems can be retrofit into vehicles with existing hydraulic systems, making them practical choices for vehicles already in production.

5. Reliability and Maintenance: HEPS and EPS systems generally have a proven track record and require minimal maintenance compared to traditional hydraulic systems with more components prone to wear and leakage. SBW systems introduce additional complexity, requiring robust redundancy measures for safety and reliable operation.

6. Cost Considerations: HEPS and EPS systems are typically more affordable compared to SBW systems, which involve intricate electronics and controls. Consider your budget and long-term maintenance costs when evaluating the different steering system options.

Ultimately, the decision depends on your personal preferences, driving habits, and the specific requirements of your vehicle. It is recommended to test drive vehicles equipped with different steering systems to experience the unique characteristics firsthand. Consult with automotive experts or manufacturers to ensure compatibility and suitability based on your specific needs and preferences.