Assessing the Need for Battery Replacement

Before embarking on the process of battery replacement, it’s crucial to determine whether the existing battery truly requires replacement. Several indicators can help assess the condition of the battery and whether it is time for a new one.

### Signs of a Failing Battery

- Diminished Cranking Power: If the engine is slow to start or the cranking sounds weaker than usual, it may indicate a declining battery.

- Electrical Issues: Malfunctions in electrical components, such as dimming headlights or flickering dashboard lights, can point to a failing battery.

- Age of the Battery: Typically, car batteries last around 3-5 years. If the battery is approaching this age range, it’s wise to consider a replacement, even if it appears to be functioning adequately.

- Visible Damage: Physical signs of damage, such as corrosion around the terminals or a bloated battery case, indicate potential issues that necessitate replacement.

### Testing the Battery

Prior to replacing the battery, it’s advisable to conduct a battery load test using a multimeter or seek professional assistance. This test can provide insights into the battery’s overall health and help confirm whether a replacement is warranted.

### Consulting a Professional

If there is uncertainty about the battery’s condition or the diagnosis of potential issues, consulting a qualified mechanic or technician can offer valuable insights. They can perform comprehensive diagnostics to determine if the battery needs replacement or if the issues stem from other vehicle components.

By carefully evaluating these factors, car owners can confidently decide whether a battery replacement is necessary, ensuring the optimal performance and reliability of their vehicle.

Gathering the Necessary Tools and Materials

Before initiating the battery replacement process, it’s essential to assemble the required tools and materials to facilitate a smooth and efficient procedure. Having the right equipment at hand can streamline the replacement process and minimize disruptions.

### Essential Tools

- Safety Gear: Prioritize safety by donning protective gear, including gloves and safety glasses, to shield against potential battery acid exposure and other hazards.

- Wrenches and Sockets: A set of wrenches and sockets, preferably in various sizes, will be necessary to loosen and tighten battery terminals and hold-down clamps.

- Battery Cleaning Solution: To address corrosion on the terminals and nearby areas, a battery cleaning solution or a mixture of baking soda and water can be used.

- Battery Terminal Brush: This specialized brush aids in cleaning corrosion from the battery terminals, ensuring optimal contact and electrical flow.

- Battery Carrier or Lifting Strap: As car batteries can be heavy and cumbersome, a carrier or lifting strap can assist in safely removing and installing the battery.

### Required Materials

- New Battery: Ensure the replacement battery is compatible with the vehicle’s make and model, with the correct specifications and terminal orientation.

- Corrosion Inhibitor: Applying a corrosion inhibitor or grease to the battery terminals after installation can help prevent future corrosion buildup.

- Shop Rags: Having a supply of shop rags or paper towels on hand can aid in cleaning any spills or messes that may occur during the replacement process.

- Battery Terminal Protectors: These protective covers can be utilized to shield the battery terminals from corrosion and damage.

- Battery Hold-Down Kit: If the existing hold-down components are worn or damaged, a replacement hold-down kit may be necessary to secure the new battery in place.

By ensuring the availability of these tools and materials, individuals can proceed with confidence, knowing they are well-equipped to carry out the battery replacement with precision and safety.

Preparing the Vehicle for Battery Replacement

Prior to initiating the battery replacement process, it is vital to prepare the vehicle to ensure a safe and efficient procedure. Taking the necessary precautions and preparing the surrounding area can contribute to a seamless replacement experience.

### Safety Measures

- Park the Vehicle: Position the vehicle in a well-ventilated and well-lit area, away from traffic, to ensure a safe working environment.

- Turn off the Engine: Before commencing any work, switch off the engine and allow it to cool down to prevent accidental electrical surges or moving parts.

- Engage the Parking Brake: Secure the vehicle by engaging the parking brake to prevent any unexpected movement during the battery replacement process.

- Ensure Proper Ventilation: As battery-related tasks may lead to the release of potentially harmful gases, it is advisable to work in a well-ventilated area to minimize exposure.

### Identifying the Battery Location

Locate the vehicle’s battery within the engine compartment or trunk, depending on the specific make and model. Refer to the owner’s manual if unsure about the battery’s placement.

### Clearing the Work Area

Remove any clutter, tools, or objects near the battery location to create a clear and unobstructed workspace. This step minimizes the risk of accidental damage to the vehicle or the new battery during the replacement process.

### Disconnecting the Negative Terminal

Prior to handling the battery, disconnect the negative terminal first using a wrench or socket of the appropriate size. This precaution prevents accidental electrical contact and reduces the risk of short circuits or electrical hazards.

By meticulously preparing the vehicle and its surroundings, individuals can lay the groundwork for a safe, organized, and efficient battery replacement process. These preparatory steps contribute to a smooth transition from the old battery to the new one, ensuring a successful outcome.

Removing the Old Battery

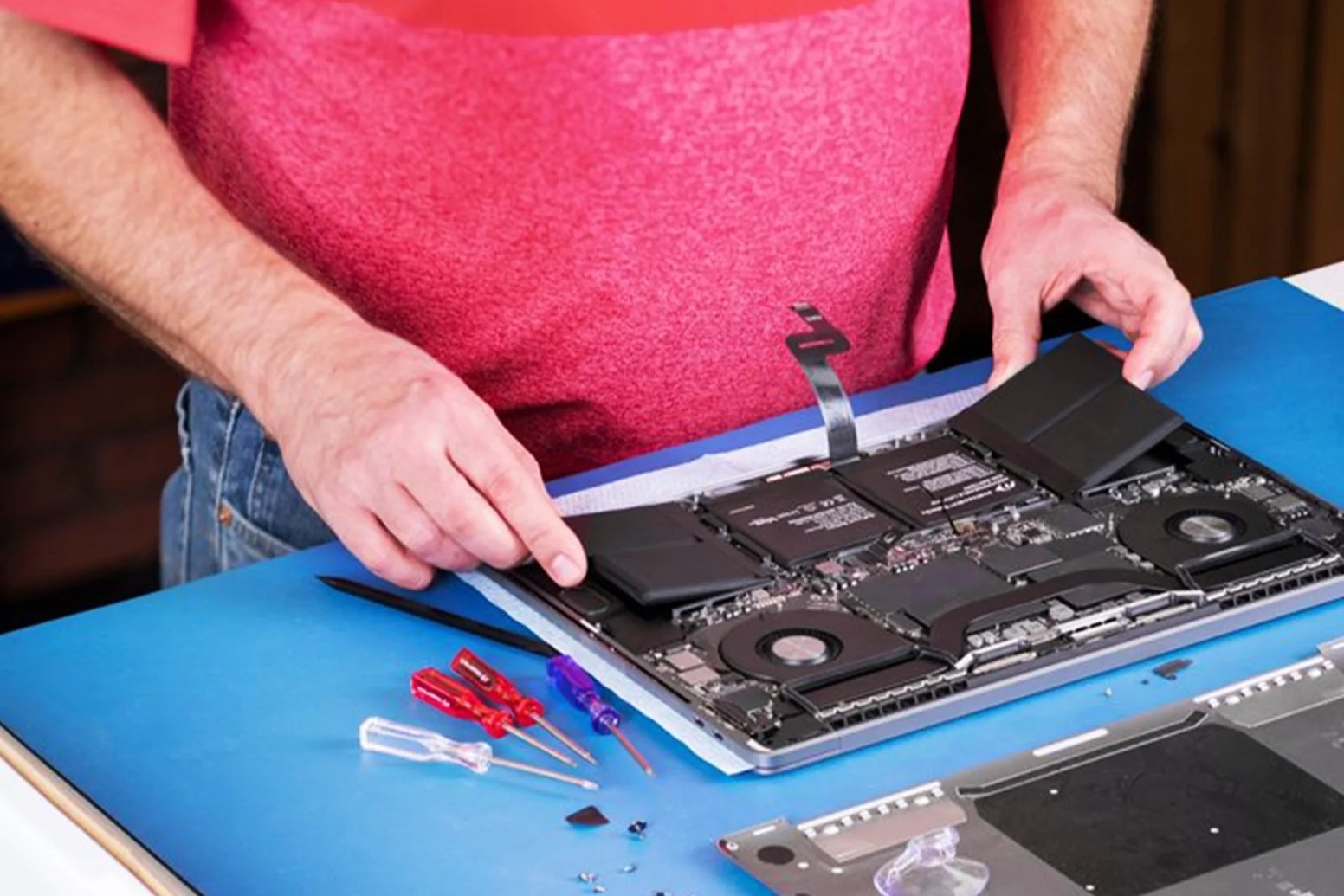

Once the vehicle and work area are prepared, the process of removing the old battery can commence. This step-by-step guide outlines the systematic approach to safely and effectively remove the existing battery from the vehicle.

### Step 1: Disconnecting the Battery Cables

Using a wrench or socket, loosen and remove the bolts or nuts securing the battery cables to the terminals. Start with the negative terminal, followed by the positive terminal. Gently wiggle the cables if they are stuck, being cautious to avoid damaging the terminals or cable ends.

### Step 2: Removing the Battery Hold-Down

Inspect the battery hold-down, often in the form of a bracket or clamp, securing the battery in place. Loosen and remove the hold-down using the appropriate tools, ensuring it is detached from the battery and the vehicle’s frame or battery tray.

### Step 3: Lifting the Old Battery

With the hold-down removed and the cables disconnected, carefully lift the old battery out of its compartment. Exercise caution, as car batteries can be heavy and should be handled with care to prevent strain or injury.

### Step 4: Inspecting the Battery Tray

Once the old battery is removed, inspect the battery tray or compartment for any signs of corrosion, debris, or damage. Clean the area using a suitable cleaning solution and ensure it is dry before proceeding with the installation of the new battery.

### Step 5: Proper Handling and Disposal

Handle the old battery with care, avoiding tipping or shaking it to prevent spills or leaks. If the battery is damaged or leaking, take precautions to avoid direct contact and utilize appropriate safety measures. When disposing of the old battery, adhere to local regulations and recycling guidelines to ensure environmentally responsible disposal.

By following these steps attentively, individuals can safely and methodically remove the old battery, setting the stage for the subsequent installation of the new battery with precision and confidence.

Installing the New Battery

With the old battery successfully removed, the installation of a new battery is the next critical step in the replacement process. Proper installation ensures the seamless integration of the new battery into the vehicle’s electrical system, promoting reliable performance and longevity.

### Step 1: Placing the New Battery

Carefully position the new battery in the designated compartment, ensuring it is oriented correctly with the positive and negative terminals aligned with the corresponding cables.

### Step 2: Securing the Battery

Reattach the battery hold-down, securing the new battery in place to prevent movement or dislodging during vehicle operation. Tighten the hold-down securely to maintain the battery’s stability.

### Step 3: Reconnecting the Battery Cables

Begin with the positive terminal, affixing the cable and tightening the connection using the appropriate wrench or socket. Subsequently, reconnect the negative terminal, ensuring a snug and secure attachment.

### Step 4: Applying Terminal Protection

Apply a thin layer of corrosion inhibitor or grease to the battery terminals to inhibit corrosion and promote optimal electrical conductivity. Additionally, install terminal protectors to shield the terminals from environmental elements and minimize the risk of corrosion buildup.

### Step 5: Conducting a Visual Inspection

Thoroughly inspect the newly installed battery, ensuring all connections are secure, and there are no loose cables or components. Verify that the battery is firmly seated and positioned correctly within the compartment.

### Step 6: Testing the Electrical System

Turn the vehicle’s ignition to verify that the electrical systems and accessories, such as lights, radio, and power windows, function correctly. This step confirms that the new battery is seamlessly integrated and supplying power as intended.

By meticulously following these installation steps, individuals can confidently complete the integration of the new battery, fostering optimal electrical performance and ensuring the vehicle’s readiness for continued operation.

Testing the New Battery

Following the installation of a new battery, it is crucial to perform comprehensive testing to validate its functionality and confirm its seamless integration into the vehicle’s electrical system. Thorough testing ensures that the new battery operates optimally, providing reliable power to support the vehicle’s various electrical components and systems.

### Voltage Verification

Using a multimeter, measure the voltage output of the new battery. A fully charged battery typically registers around 12.6 to 12.8 volts. If the voltage falls below this range, the battery may require charging before further testing.

### Cranking Performance Test

Initiate a cranking test by starting the vehicle’s engine. Observe the cranking speed and the engine’s responsiveness. A healthy battery facilitates smooth and consistent engine starting, with the cranking action exhibiting adequate power and speed.

### Electrical System Assessment

Engage various electrical components and accessories, such as headlights, interior lights, windshield wipers, and the audio system, to evaluate their functionality. A robust battery should support these systems without causing dimming lights or sluggish operation.

### Charging System Evaluation

Assess the vehicle’s charging system by monitoring the battery’s voltage while the engine is running. The voltage should measure between 13.8 and 14.4 volts, indicating that the alternator is effectively charging the battery and maintaining its optimal performance.

### Ongoing Monitoring

After the initial testing, continue to monitor the battery’s performance over the following days and weeks. Pay attention to any signs of electrical issues, such as slow engine cranking, dimming lights, or unexplained battery drain, which may indicate underlying concerns with the new battery or the vehicle’s charging system.

### Professional Assessment

If there are uncertainties regarding the new battery’s performance or if any irregularities are observed during testing, consulting a qualified mechanic or technician for a comprehensive battery and electrical system assessment can provide valuable insights and ensure the vehicle’s optimal functionality.

Thorough testing of the new battery, encompassing various performance evaluations and ongoing monitoring, is essential to confirm its reliability and suitability for sustaining the vehicle’s electrical demands, promoting a seamless transition to the new power source.

Proper Disposal of the Old Battery

Disposing of the old battery responsibly is a critical aspect of the battery replacement process. Car batteries contain hazardous materials, including lead and sulfuric acid, necessitating careful handling and environmentally conscious disposal methods to mitigate potential harm to human health and the ecosystem.

### Local Regulations and Recycling Centers

Check local regulations and guidelines regarding the disposal of automotive batteries. Many jurisdictions have specific protocols for battery disposal and recycling. Identify authorized recycling centers or collection points where old batteries can be safely deposited for proper handling and recycling.

### Battery Recycling Benefits

Old car batteries are highly recyclable, with the lead and plastic components being valuable resources for manufacturing new batteries and other products. Recycling batteries helps conserve natural resources, reduces environmental pollution, and minimizes the need for raw material extraction, making it a sustainable and eco-friendly practice.

### Transportation and Handling

When transporting the old battery to a recycling facility, take precautions to prevent leaks, spills, or damage. Secure the battery in an upright position, ideally in a sturdy container or a battery box, to minimize the risk of acid leaks or exposure during transit.

### Exchange Programs

Explore exchange programs offered by automotive retailers, where the old battery can often be returned when purchasing a new one. Some retailers may offer incentives or discounts for returning old batteries, encouraging responsible disposal while providing a convenient solution for consumers.

### Environmental Impact

Improper disposal of car batteries can lead to soil and water contamination, posing significant risks to ecosystems and public health. By choosing responsible disposal methods, individuals contribute to the preservation of the environment and the reduction of potential harm caused by hazardous battery components.

### Compliance with Regulations

Adhere to all local, state, and federal regulations governing the disposal of automotive batteries. By following established guidelines and utilizing authorized disposal channels, individuals uphold legal requirements and contribute to the collective effort of safeguarding the environment and public well-being.

By conscientiously managing the disposal of old car batteries through recycling and adherence to regulatory standards, individuals play a vital role in promoting sustainable practices and environmental stewardship, ensuring the safe and responsible handling of hazardous battery components.