Types of Fuel Strainers

Fuel strainers are essential components in various fuel systems, ensuring clean and debris-free fuel flows into the engine. These strainers come in different types, designed to cater to specific fuel systems and filtration needs. Let’s explore some common types of fuel strainers:

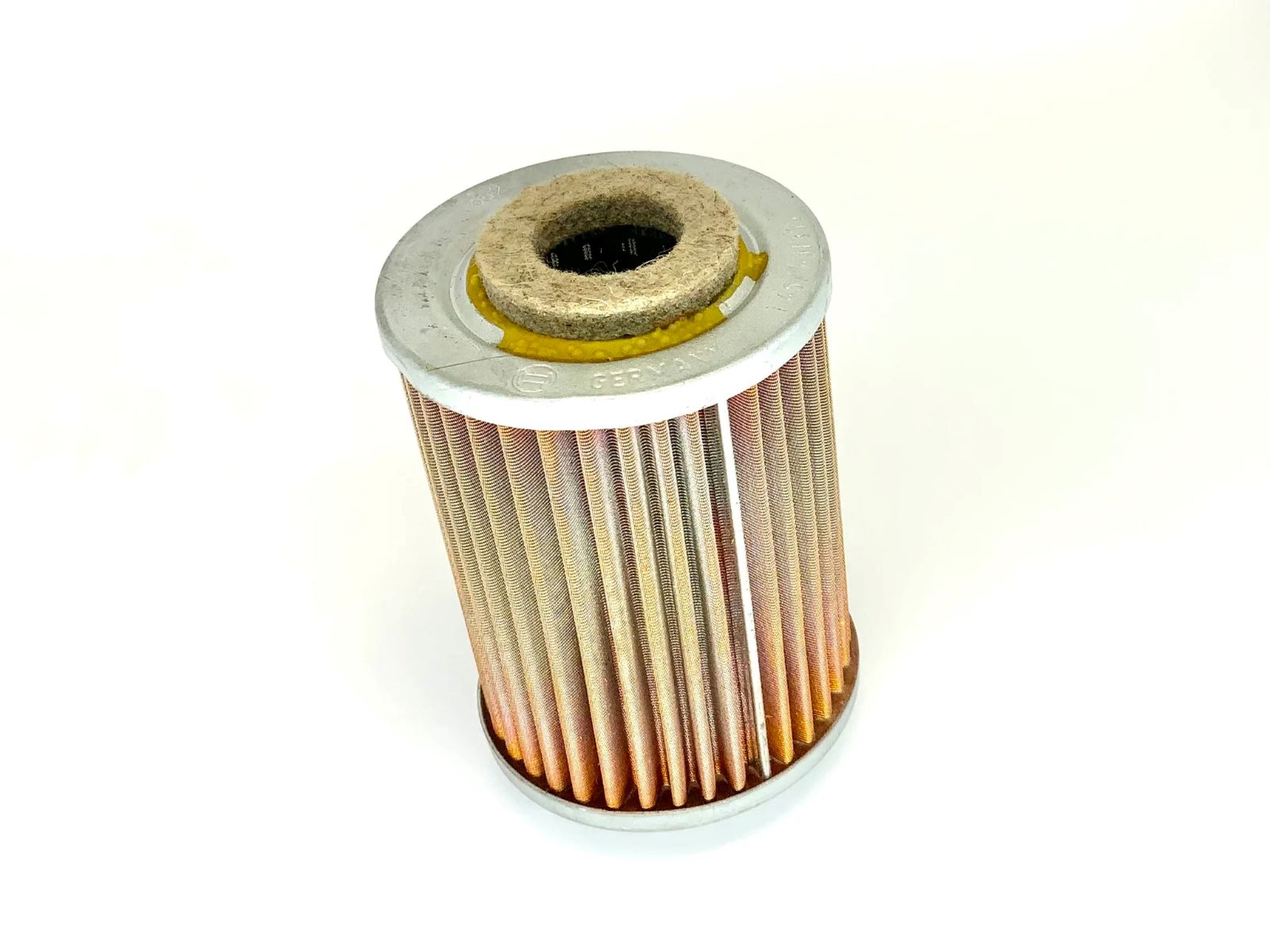

1. Inline Fuel Strainer: This type of fuel strainer is installed in the fuel line between the fuel tank and the engine. It acts as a barrier, capturing and preventing contaminants such as dirt, rust, and sediment from entering the engine. Inline fuel strainers are usually made of metal or synthetic materials and are easily accessible for cleaning or replacement.

2. Fuel Tank Strainer: As the name suggests, this type of fuel strainer is located inside the fuel tank. It serves as the first line of defense, preventing larger particles and debris from entering the fuel system. Fuel tank strainers are often mesh screens or fine mesh socks that trap contaminants before they reach the fuel pump or injectors.

3. Carburetor Strainer: Carburetors, commonly found in older vehicles or small engines, utilize carburetor strainers to filter fuel. These strainers are usually located between the fuel inlet and the float chamber in the carburetor. They help prevent debris or impurities from obstructing the carburetor jets, ensuring fuel flows smoothly into the engine.

4. Fuel Injector Strainer: Modern fuel-injected engines employ fuel injector strainers to maintain the cleanliness of the fuel injectors. These small filters are located within the fuel injectors themselves and serve as a protective barrier. They remove tiny particles and contaminants that could potentially clog the injectors and affect fuel atomization and combustion efficiency.

5. Spin-on Fuel Filter/Strainer: Some fuel systems incorporate a spin-on fuel filter/strainer, which combines a filtration element and a housing. These filters are typically used in diesel vehicles or heavy machinery, where larger volumes of fuel need to be filtered. The spin-on design allows for easy replacement of the filtration element when it becomes clogged or contaminated.

It’s important to note that the specific type of fuel strainer required may vary depending on the vehicle or equipment you’re dealing with. Consulting the manufacturer’s recommendations and guidelines is vital to ensure proper filtration and optimal engine performance. Regular inspection, cleaning, and replacement of fuel strainers are essential to maintain the integrity of the fuel system and prolong the life of the engine.

The Purpose of a Fuel Strainer

A fuel strainer serves a crucial role in the function and longevity of a vehicle’s fuel system. It is designed to remove impurities and contaminants from the fuel before it reaches the engine. Let’s dive deeper into the purpose of a fuel strainer:

1. Contaminant Removal: The primary purpose of a fuel strainer is to keep harmful contaminants, such as dirt, rust, debris, and sediment, from entering the fuel system. These particles can cause significant damage to the fuel injectors, fuel pump, carburetor, or other components if allowed to circulate freely. The strainer acts as a barrier, capturing these contaminants and preventing them from reaching critical engine parts.

2. Protection of Fuel System Components: By removing impurities from the fuel, a fuel strainer protects various fuel system components from damage and malfunction. Clean fuel allows for proper operation of fuel injectors, carburetors, and other engine parts, ensuring optimal fuel atomization and combustion. This improves fuel efficiency, performance, and reduces the risk of costly repairs.

3. Prolonging Engine Life: A fuel strainer plays a vital role in extending the lifespan of the engine. By preventing contaminants from entering the fuel system, it reduces the likelihood of abrasive particles causing wear and tear on internal components. Clean fuel also minimizes the chances of clogged injectors or carburetor jets, reducing the strain on the engine and promoting smoother running.

4. Preventing Fuel System Blockages: Fuel strainers help maintain a consistent flow of fuel by preventing blockages in the fuel system. By capturing larger contaminants, the strainer prevents them from clogging fuel lines, fuel filters, or injectors, which can lead to fuel starvation or improper fuel delivery. Ensuring proper fuel flow is essential for the engine’s smooth operation.

5. Preserving Fuel Quality: Fuel strainers also help preserve the quality of the fuel. Contaminants in the fuel can deteriorate its stability and affect its combustion properties. By removing impurities, the strainer helps maintain fuel quality, ensuring efficient combustion and reducing the risk of engine misfires, rough idling, or reduced power.

In summary, the purpose of a fuel strainer is to safeguard the fuel system components, maintain fuel quality, and extend the engine’s lifespan. Regular inspection, cleaning, and replacement of the fuel strainer are crucial to ensure its effectiveness and ensure the smooth operation and longevity of the vehicle’s engine.

How Does a Fuel Strainer Work?

A fuel strainer operates by filtering the fuel as it flows through the fuel system, ensuring that any impurities or contaminants are captured before reaching the engine. Understanding how a fuel strainer works can shed light on its significance in maintaining clean and efficient fuel delivery. Here’s a breakdown of the fuel strainer’s functioning:

1. Fuel Flow: As fuel is drawn from the fuel tank, it passes through the fuel lines towards the engine. Along this path, the fuel strainer is strategically placed to intercept the flowing fuel. Before entering the fuel system components, the fuel must first pass through the strainer.

2. Filtration Element: The heart of a fuel strainer is the filtration element. Typically made of fine mesh screens or synthetic materials, the filtration element contains tiny pores or holes. These pores are designed to allow fuel molecules to pass through while capturing larger particles such as dirt, rust, debris, and sediment.

3. Capturing Contaminants: As the fuel flows through the filtration element, any contaminants present in the fuel are trapped or blocked by the fine mesh or synthetic material. The size of the filtration element pores is carefully chosen to ensure the effective capture of contaminants without obstructing the fuel flow.

4. Preventing Blockages: The captured contaminants accumulate on the surface of the filtration element, forming a layer of debris. This layer can build up over time, depending on the fuel quality and usage conditions. However, the strainer is designed to continue allowing fuel to flow through while still capturing contaminants. This prevents the formation of blockages in the fuel system and ensures proper fuel delivery to the engine.

5. Accessible for Maintenance: Fuel strainers are typically designed to be easily accessible for cleaning or replacement. Regular maintenance is crucial to keep the strainer operating at its best. Depending on the vehicle or equipment, the strainer can be cleaned manually by removing the filtration element and rinsing it with clean fuel or replacing the entire strainer if the element is not replaceable.

Overall, a fuel strainer works by intercepting the fuel flow and filtering out contaminants using a fine mesh or synthetic filtration element. By capturing impurities, the strainer helps prevent damage to fuel system components, ensures optimal fuel flow, and promotes the longevity and efficiency of the engine. Regular inspection and maintenance of the fuel strainer are essential to maintain its effectiveness and ensure a clean and reliable fuel supply to the engine.

Why Is a Fuel Strainer Important?

A fuel strainer plays a vital role in maintaining the cleanliness and integrity of a vehicle’s fuel system. Understanding the importance of a fuel strainer helps highlight its significance in ensuring optimal engine performance and longevity. Here are key reasons why a fuel strainer is important:

1. Contaminant Removal: One of the primary reasons a fuel strainer is crucial is its ability to remove contaminants from the fuel. Fuel can contain various impurities such as dirt, rust, debris, and sediment that can accumulate over time or enter the fuel system during refueling. These contaminants have the potential to clog fuel lines, injectors, or carburetors, leading to reduced fuel flow, engine performance issues, or even complete fuel system failure. The fuel strainer captures these impurities, preventing them from reaching critical engine components.

2. Protection of Fuel System Components: A fuel strainer acts as a safeguard for fuel system components, including fuel pumps, injectors, and carburetors. Contaminants in the fuel can cause significant damage to these sensitive parts, leading to expensive repairs or replacements. By removing impurities, the strainer helps ensure that clean fuel is delivered to these components, promoting efficient operation and extending their lifespan.

3. Optimal Engine Performance: Clean fuel is essential for the optimal performance of an engine. A fuel strainer ensures that fuel is filtered before it enters the engine, allowing for proper fuel atomization and combustion. When the fuel is free from contaminants, the engine can burn fuel efficiently, resulting in improved power, fuel economy, and reduced emissions. A fuel strainer helps maintain consistent fuel flow, preventing interruptions or irregularities that can impact engine performance.

4. Prevention of Fuel System Blockages: Fuel system blockages can have detrimental effects on the overall operation of the engine. A clogged fuel line or injector can disrupt the fuel supply, leading to engine misfires, rough idling, or stalling. By capturing contaminants, a fuel strainer helps prevent blockages and ensures a smooth and uninterrupted fuel flow, preserving the engine’s performance and reliability.

5. Longevity of the Engine: Proper filtration provided by a fuel strainer contributes to the longevity of the engine. By preventing contaminants from entering critical engine components, the strainer helps reduce wear and tear, minimizing the risk of premature engine failure. A clean fuel system is less prone to damage, allowing the engine to operate optimally for an extended period.

In summary, a fuel strainer is important for removing contaminants from the fuel, protecting fuel system components, promoting optimal engine performance, preventing fuel system blockages, and prolonging the engine’s lifespan. Regular maintenance and inspection of the fuel strainer are essential to ensure its effectiveness and ensure a clean and reliable fuel supply, ultimately enhancing the overall performance and durability of the vehicle’s engine.

Signs of a Clogged Fuel Strainer

A clogged fuel strainer can have detrimental effects on a vehicle’s performance and fuel system. It’s important to be aware of the signs that indicate a potential issue with the fuel strainer. Identifying these signs early can help prevent further damage and ensure proper maintenance. Here are some common signs of a clogged fuel strainer:

1. Engine Stall or Hesitation: A clogged fuel strainer can restrict the flow of fuel to the engine, resulting in engine stall or hesitation. If you notice that the engine frequently stalls or hesitates during acceleration, it could be an indicator of a clogged fuel strainer.

2. Poor Engine Performance: A clogged fuel strainer deprives the engine of the proper fuel supply, leading to reduced engine performance. You may experience a loss of power, sluggish acceleration, or difficulty starting the engine. These performance issues can be a result of fuel flow restrictions caused by a clogged strainer.

3. Decreased Fuel Efficiency: A clogged fuel strainer can disrupt the fuel-air mixture, affecting the engine’s efficiency. If you notice a sudden drop in fuel efficiency, where you need to refuel more frequently or your fuel economy is significantly reduced, it could be a sign of a clogged strainer.

4. Engine Misfires: A clogged fuel strainer can contribute to engine misfires, which occur when the fuel-air mixture is inconsistent or incomplete. Misfires can result in rough idling, engine sputtering, or a noticeable decrease in engine power. If you experience frequent engine misfires, it’s worth checking the condition of the fuel strainer.

5. Inconsistent or Rough Idling: A clogged fuel strainer can disrupt the fuel flow, leading to inconsistent or rough idling. You may notice that the engine has difficulty maintaining a steady idle speed or that it runs unevenly. If you experience these idling issues, it’s worth investigating the fuel strainer as a possible culprit.

6. Fuel System Warning Light: In some vehicles, a clogged fuel strainer can trigger the fuel system warning light on the dashboard. If the light illuminates, it is advised to have the fuel system inspected, including the fuel strainer, to determine the cause of the warning.

If you notice any of these signs, it is essential to address the potential issue with the fuel strainer promptly. Cleaning or replacing the clogged strainer can restore proper fuel flow and prevent further damage to the fuel system. Regular maintenance and inspection of the fuel strainer can help prevent clogs and maintain the efficiency and performance of the vehicle’s engine.

How to Clean a Fuel Strainer

Cleaning a fuel strainer is an important maintenance task that helps ensure the proper functioning of the fuel system. Regular cleaning of the fuel strainer can prevent clogs and maintain optimal fuel flow. Here are the steps to clean a fuel strainer:

1. Prepare the Necessary Tools: Before starting, gather the tools and materials needed for the task. This may include safety gloves, safety glasses, a wrench or pliers (depending on the strainer type), clean shop towels, a bucket, and fuel-safe cleaning solution.

2. Safety Precautions: Ensure the engine is turned off and the vehicle is in a well-ventilated area. It is also recommended to disconnect the battery or turn off the fuel pump to prevent accidental fuel spills or spraying.

3. Locate the Fuel Strainer: The fuel strainer is typically located along the fuel line, near the fuel tank or the engine. Consult the vehicle’s manual or consult with a professional if you’re unsure of its location.

4. Access the Fuel Strainer: Depending on the type of fuel strainer, you may need to use a wrench or pliers to remove any retaining clips or connection fittings. Take care not to damage the fuel line or other components during the removal process.

5. Remove the Fuel Strainer: Once the strainer is accessible, carefully remove it from its mounting or connection. Be cautious as there may be fuel present in the strainer or the surrounding area.

6. Inspect and Clean: Inspect the strainer for any signs of debris or clogs. Use a clean shop towel or a soft brush to gently remove any visible contaminants. Avoid using excessive force, as it may damage the strainer.

7. Soak and Rinse: Fill a bucket with a fuel-safe cleaning solution recommended by the vehicle manufacturer or a professional mechanic. Place the fuel strainer in the solution and allow it to soak for the recommended time. Then, rinse the strainer thoroughly with clean fuel or a suitable solvent to remove any remaining debris.

8. Dry and Reinstall: Ensure the strainer is completely dry before reinstalling it. Check the fuel line connection for any signs of damage or leaks. Carefully reattach the strainer, following the proper procedure and using the necessary tools.

9. Test and Verify: Once the fuel strainer is cleaned and reinstalled, start the engine and let it run for a few minutes. Monitor for any abnormal engine behavior or fuel-related issues. If the engine runs smoothly, it indicates that the fuel strainer is functioning properly.

Regular cleaning of the fuel strainer is recommended as part of routine maintenance. However, if the strainer appears heavily damaged, excessively clogged, or if cleaning does not resolve fuel system issues, it may be necessary to replace the strainer entirely. Seek professional advice or consult the vehicle’s manual in such cases.

By following these steps, you can effectively clean the fuel strainer, ensuring a clean and uninterrupted fuel flow, and promoting the efficient operation of the vehicle’s fuel system.

When Should You Replace a Fuel Strainer?

The fuel strainer plays a crucial role in maintaining the cleanliness and proper functioning of the fuel system. Over time, it can become compromised or worn out, requiring replacement. Knowing when to replace a fuel strainer is important to ensure the integrity of your vehicle’s fuel system. Here are some indicators that it may be time to replace the fuel strainer:

1. Clogged or Restricted Flow: If the fuel strainer becomes severely clogged or blocked, it may impede fuel flow through the system. This can result in engine performance issues, including stalling, hesitation, or loss of power. If cleaning the strainer does not resolve the flow restriction, it is likely time to replace it.

2. Excessive Debris Accumulation: During regular strainer maintenance, if you notice a significant amount of debris or contaminants that cannot be easily cleaned, it indicates that the strainer is no longer effectively filtering the fuel. Excessive debris accumulation may lead to increased wear on fuel system components and negatively impact engine performance.

3. Fuel System Warning Light: If the fuel system warning light on your vehicle’s dashboard illuminates, it could indicate a problem with the fuel strainer or the fuel system as a whole. Consult the vehicle’s manual or a professional mechanic to determine the cause. If the issue is related to the strainer, replacement may be necessary.

4. High Mileage or Age: Fuel strainers, like other components, can wear out over time. If your vehicle has high mileage or is older, it is recommended to consider replacing the fuel strainer as a preventive measure. This helps ensure the continued proper function of the fuel system and avoids potential issues associated with an aging strainer.

5. Manufacturer’s Recommendations: Consult the vehicle’s manual or reach out to the manufacturer for recommended maintenance intervals or replacement guidelines. Different vehicles may have different recommendations based on factors such as model, engine type, and fuel system design. Adhering to these guidelines can help prevent potential fuel system problems.

6. Unresolved Fuel System Issues: If you are experiencing persistent fuel-related problems, despite regular maintenance and cleaning of the strainer, it may indicate that the strainer is no longer effective. Replacing the strainer can help address the underlying issue and restore proper fuel flow and engine performance.

It is important to note that the lifespan of a fuel strainer can vary depending on factors such as fuel quality, driving conditions, and maintenance practices. Regular inspection, cleaning, and replacement, as needed, are essential to ensure the integrity and efficiency of the fuel system.

Ultimately, if you suspect that your fuel strainer is compromised or if you experience any of the mentioned issues, it is advisable to consult a professional mechanic to properly diagnose the problem and provide appropriate guidance on whether a replacement is necessary.

Common Issues with Fuel Strainers

Fuel strainers, like any other automotive component, can experience issues over time. Identifying common problems with fuel strainers is essential in diagnosing and resolving fuel system issues. Here are some common issues that can arise with fuel strainers:

1. Clogged Strainer: One of the most common issues with fuel strainers is clogging due to the accumulation of debris, dirt, rust, or sediment. A clogged strainer restricts fuel flow and can cause engine performance problems like stalling, hesitation, or reduced power.

2. Worn or Damaged Filtration Element: The filtration element in a fuel strainer can degrade or become damaged over time. This can occur due to normal wear and tear or exposure to harsh contaminants. When the filtration element is compromised, it may allow impurities to bypass the strainer and enter the fuel system.

3. Failure of Seals or Gaskets: Fuel strainers have seals or gaskets that help maintain a proper seal and prevent fuel leaks. Over time, these seals or gaskets can deteriorate, leading to fuel leaks or improper sealing of the strainer housing. Fuel leaks pose a safety risk and can adversely affect engine performance.

4. Corrosion or Rust: Fuel strainers, particularly those exposed to external elements or harsh conditions, can develop corrosion or rust. Corrosion can weaken the strainer housing or components, potentially leading to fuel leaks or structural damage. Rust particles can also dislodge and contaminate the fuel system, causing further issues.

5. Incorrect Installation: Improper installation of a fuel strainer can cause issues with its fitment and alignment within the fuel system. Incorrect installation may result in fuel leaks, misalignment of fuel lines, or disruption of fuel flow, leading to fuel delivery problems and engine performance issues.

6. Environmental Contaminants: Exposure to environmental contaminants, such as water or excessive moisture, can impact the performance of a fuel strainer. Moisture can cause corrosion or promote the growth of microbial contaminants, leading to fuel system issues. Additionally, water or moisture in the fuel can lead to fuel system corrosion or damage.

7. Excessive Wear: Fuel strainers, especially in vehicles with high mileage or those subjected to harsh driving conditions, can experience excessive wear. This can cause the filtration element to lose its effectiveness in capturing contaminants, leading to reduced fuel system performance.

If you encounter any of these common issues with your fuel strainer, it is recommended to address them promptly. Consult a professional mechanic to properly diagnose the problem and determine whether the strainer can be cleaned, repaired, or requires replacement. Regular inspection and maintenance of the fuel strainer can help prevent these issues and ensure the proper functioning of the fuel system.

Tips for Proper Maintenance of Fuel Strainer

To ensure the optimal performance and longevity of your vehicle’s fuel strainer, regular maintenance is crucial. Proper maintenance helps prevent fuel system issues and keeps the fuel strainer functioning effectively. Here are some essential tips for the proper maintenance of a fuel strainer:

1. Follow Manufacturer’s Recommendations: Consult the vehicle’s manual or reach out to the manufacturer for recommended maintenance intervals and guidelines specific to your vehicle. These recommendations may include inspection, cleaning, or replacement intervals for the fuel strainer.

2. Inspect Regularly: Regularly inspect the fuel strainer for any signs of damage, debris accumulation, or leaks. A visual inspection can help identify potential issues early on, enabling prompt action.

3. Clean the Fuel Strainer: Periodically clean the fuel strainer to remove any accumulated debris or contaminants. Follow the manufacturer’s guidelines for cleaning procedures and use fuel-safe cleaning solutions or solvents. Gently clean the strainer and ensure it is thoroughly dry before reinstalling.

4. Replace when Necessary: If the fuel strainer is heavily damaged, excessively clogged, or cleaning does not resolve fuel system issues, it is time to replace the strainer. Follow the manufacturer’s recommendations for replacement intervals or consult a professional mechanic for guidance.

5. Consider Fuel Quality: Ensure you are using clean and high-quality fuel. Contaminated or poor-quality fuel can affect the performance of the fuel strainer and the entire fuel system. If possible, avoid filling up at gas stations with a reputation for low-quality fuel.

6. Monitor Fuel Additives: Be cautious when using fuel additives and ensure they are compatible with your vehicle’s fuel system. Some additives may cause damage to the fuel strainer or other components. Follow the recommended dosage and consult the manufacturer or a professional if unsure.

7. Address Fuel System Issues Promptly: If you notice any fuel-related issues such as poor engine performance, fuel leaks, or abnormal engine behavior, address them promptly. Ignoring fuel system issues can lead to further damage and costly repairs.

8. Protect from Environmental Contaminants: Take precautions to protect the fuel system, including the fuel strainer, from environmental contaminants such as excessive moisture, water, or dirt. Park in covered or protected areas and avoid driving through deep water or extremely dusty conditions.

9. Consult a Professional: If you are unsure about any aspect of fuel strainer maintenance or encounter persistent fuel system issues, it is advisable to consult a professional mechanic or technician. They can provide expert guidance, diagnose problems accurately, and perform necessary repairs or replacements.

By following these tips, you can ensure the proper maintenance of the fuel strainer and promote the overall health of your vehicle’s fuel system. Regular inspection, cleaning, and replacement, as needed, will help keep the fuel strainer functioning effectively, ensuring clean fuel flow and optimal engine performance.