Measuring and Marking

Before you begin cutting a wire shelf, it’s essential to properly measure and mark the area that needs to be cut. This ensures that you make precise cuts and maintain the integrity of the shelf.

First, take accurate measurements of the length you want the shelf to be after cutting. Use a tape measure or ruler to measure from one end of the shelf to the desired cutting point. Make sure to measure twice to double-check your measurements. Write down the measured length to refer to it later.

Next, using a pencil or marker, mark the cutting point on the wire shelf. It’s best to use a straightedge or a piece of masking tape to ensure a straight and precise line. Align the edge of the straightedge or tape with the desired cutting point and draw a line across the width of the shelf. This line will serve as your cutting guide.

Additionally, it’s important to mark any additional modifications you may want to make, such as drilling holes or adding hooks. Measure and mark these points accordingly using a measuring tape and a pencil or marker.

Remember to measure and mark both sides of the wire shelf if you need to cut from the middle. This will help you maintain symmetry and evenness in your cuts.

By taking the time to measure accurately and mark the cutting points, you’ll ensure a successful wire shelf cutting process with clean and precise results.

Choosing the Right Tools

When it comes to cutting a wire shelf, having the right tools can make all the difference in achieving clean and precise cuts. Here are the essential tools you’ll need:

- Wire Cutters: Invest in a high-quality pair of wire cutters specifically designed for cutting metal. Look for cutters with a sharp cutting edge and ergonomic handles for comfortable use.

- Measuring Tape: A measuring tape is essential for accurately measuring the length you want to cut the wire shelf. Opt for a durable tape measure with clear and easy-to-read markings.

- Marker or Pencil: A marker or pencil is needed for marking the cutting points on the wire shelf. Choose a marker or pencil that is smudge-proof and visible on the wire surface.

- Safety Gloves, Goggles, and Mask: Since cutting wire can produce sharp edges and metal shards, it’s crucial to protect yourself. Wear safety gloves to protect your hands, goggles to shield your eyes, and a mask to prevent inhalation of any debris.

- Safety Glasses:

- Workbench or Stable Surface: Ensure you have a stable workbench or surface to securely hold the wire shelf while cutting. This will provide stability and prevent any accidental slips.

- File or Sandpaper: After cutting the wire, you may need a file or sandpaper to smooth out any rough edges or burrs. This will help create a clean and polished finish.

Wire shelves often have a protective coating or paint that can chip or break during cutting. Safety glasses will protect your eyes from any flying debris or particles.

It’s important to choose high-quality tools that are specifically designed for cutting wire shelves. Investing in the right tools will not only make the cutting process easier but also result in professional-looking cuts.

Safety Precautions

When working with wire shelves and cutting tools, safety should be your top priority. Follow these important safety precautions to protect yourself and ensure a safe cutting process:

- Wear Safety Gear: Always wear safety gloves, goggles, and a mask when cutting wire shelves. Gloves will protect your hands from sharp edges, goggles will shield your eyes from flying debris, and a mask will prevent inhalation of any metal particles.

- Choose a Well-Ventilated Area: Work in a well-ventilated area or use a fan to minimize the build-up of dust and metal particles. Adequate ventilation will help you breathe easier and reduce the risk of respiratory issues.

- Secure the Shelf: Ensure the wire shelf is securely fastened to a stable surface or workbench. This will prevent it from moving or slipping while you are cutting, reducing the risk of injuries.

- Use the Right Cutting Tools: Make sure to use the appropriate wire cutters for cutting metal. Using the wrong tools can lead to inefficient cutting or damage to the wire shelf.

- Take Breaks: Cutting wire shelves can be physically demanding. Take regular breaks to avoid fatigue and maintain focus, especially if you’re working on a large project.

- Inspect the Wire Shelf: Before cutting, inspect the wire shelf for any damage, such as sharp edges, rust, or structural issues. Address any problems before proceeding with the cutting process.

- Clean Up the Workspace: Keep your work area clean and free from clutter. Store tools properly and dispose of any metal scraps or debris safely to prevent accidents or tripping hazards.

- Follow Manufacturer Instructions: If the wire shelf comes with specific cutting instructions from the manufacturer, be sure to follow them carefully. This will ensure that you maintain any warranty or guarantee on the product.

- Take your Time: Cutting wire shelves requires precision. Avoid rushing the process and take your time to make accurate and controlled cuts. This will reduce the risk of mistakes or injuries.

By following these safety precautions, you can minimize the risk of accidents and injuries while cutting wire shelves. Remember, safety should always be your priority when working with any cutting tools and materials.

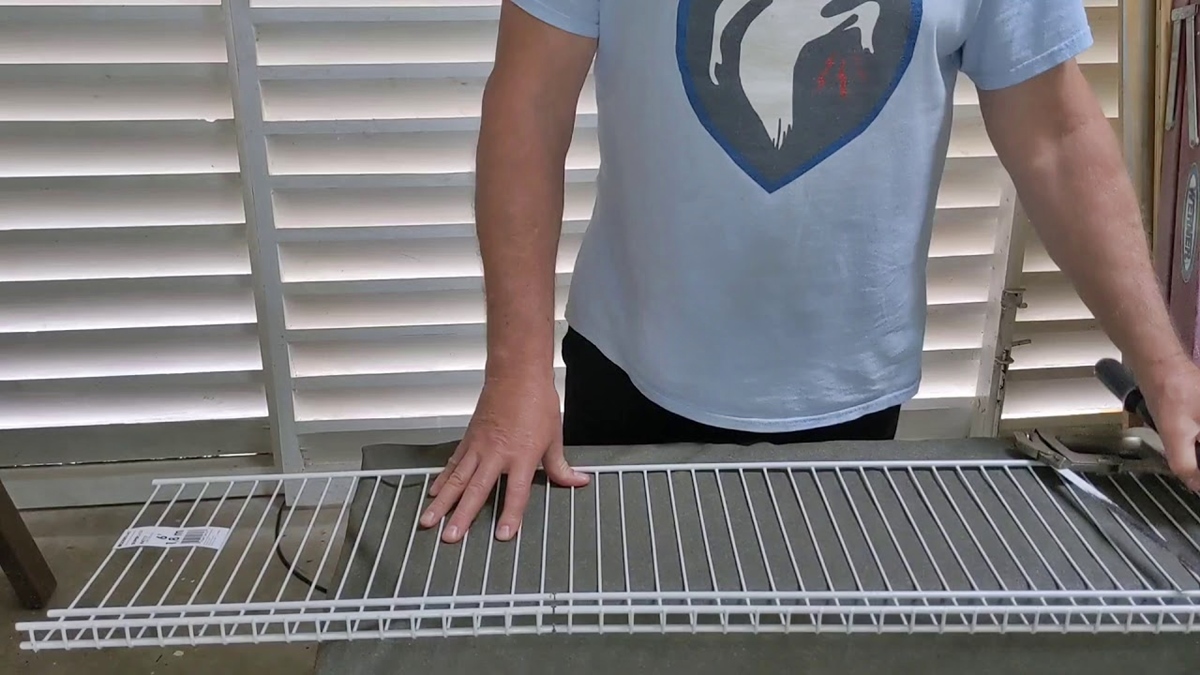

Removing the Shelf

Before you can begin cutting the wire shelf, you need to remove it from its current location. Here’s a step-by-step guide on how to remove the shelf safely:

- Clear the Area: Ensure the area around the wire shelf is clear of any obstacles or items that may get in the way during removal. This will provide you with ample space to work.

- Empty the Shelf: Remove all items from the wire shelf and set them aside. It’s important to have a clear and empty shelf to make the removal process easier.

- Release Shelf Supports: Some wire shelves are held in place by support brackets or clips. Locate these supports and release them using a screwdriver or by following the manufacturer’s instructions.

- Slide the Shelf Out: If the wire shelf is adjustable or has a slide-out mechanism, carefully slide it out of its position. If it’s a fixed shelf, lift it slightly to release it from any hooks or railing that may be holding it in place and then slide it out.

- Store the Shelf Safely: Once the wire shelf is removed, find a safe and secure place to store it until you are ready to cut it. Protect it from any damage or impact that could compromise its structural integrity.

Remember, it’s crucial to handle the wire shelf with care during the removal process to avoid any injuries or damage to the shelf or surrounding areas. Take your time and be gentle when releasing and sliding the shelf out of position.

Cutting the Wire

Now that you have prepared the wire shelf and are ready to make the desired cut, it’s time to start cutting the wire. Follow these steps to ensure a clean and precise cut:

- Put on Safety Gear: Before you begin, put on your safety gloves, goggles, and mask to protect yourself from any sharp edges or metal particles.

- Position the Wire: Place the wire shelf on a stable surface or workbench, ensuring it is securely held in place. This will provide stability and prevent any accidental movement while cutting.

- Align the Cutting Point: Align the cutting point, marked in the previous steps, with the cutting jaws of your wire cutters.

- Apply Pressure: Grip the wire cutters firmly and start applying even pressure to the wire. Use the cutting edge of the wire cutters to cut through the wire.

- Cut in Stages: For thicker wire shelves, it may be necessary to cut in stages to prevent the wire cutters from becoming damaged or the cut from becoming uneven. Make multiple cuts along the marked cutting line, gradually working your way through the wire.

- Take Breaks if Needed: If the cutting process becomes physically demanding or if you need to readjust your grip, take breaks as necessary. This will help you maintain control and ensure accurate cuts.

- Inspect the Cut: Once the wire is cut, inspect the edges for any rough spots or burrs. If necessary, use a file or sandpaper to smooth out the cut edges.

Remember to take your time and work slowly and steadily when cutting the wire. Rushing can lead to uneven cuts or accidents. It’s crucial to wear your safety gear throughout the entire cutting process to prevent any injuries.

Once you have achieved a clean and precise cut, you are ready to move on to the next step: finishing the cut.

Finishing the Cut

After cutting the wire shelf, it’s important to give the cut edges a polished and finished look. Follow these steps to ensure a professional and clean finish:

- Inspect the Cut: Begin by inspecting the cut edges of the wire shelf. Look for any rough spots, burrs, or sharp edges that require attention.

- File or Sandpaper: If you notice any roughness or burrs, use a file or sandpaper to smooth out the edges. Gently rub the file or sandpaper against the cut edges to remove any imperfections. Be careful not to apply excessive force that could damage the wire.

- Clean the Cut Area: Once you have smoothed out the edges, use a cloth or brush to clean the cut area. This will remove any metal shavings or debris that may have accumulated during the cutting process.

- Check for Stability: Before reinstalling the wire shelf, ensure that the cut section is stable and securely fastened. Wiggle or gently apply pressure to the cut area to verify its integrity. If necessary, make any further adjustments or reinforcements to ensure the shelf is safe to use.

- Test Fit the Shelf: Finally, to ensure a proper fit, test the wire shelf in its intended location. Ensure that it aligns correctly and securely in its new position.

By following these steps, you’ll achieve a clean and finished look for your cut wire shelf. Taking the time to smooth out the edges and clean the cut area will not only enhance the aesthetics but also prevent any potential injuries from sharp edges.

Once you are satisfied with the finished cut, you can proceed to reinstalling the wire shelf.

Reinstalling the Shelf

After cutting and finishing the wire shelf, it’s time to reinstall it in its new position. Here are the steps to follow:

- Clean the Installation Area: Before reinstalling the wire shelf, make sure the installation area is clean and free from any dust or debris. This will provide a clean surface for the shelf to rest on.

- Align the Shelf: Place the wire shelf in its intended position, ensuring it aligns with any existing supports, brackets, or hooks. Take your time to make sure it is centered and level.

- Secure the Shelf: If the wire shelf has adjustable or removable support brackets or clips, attach them securely to provide stability and prevent any movement. Follow the manufacturer’s instructions for proper installation.

- Double-Check the Stability: Once the shelf is installed, double-check its stability by gently pushing and pulling on it. Ensure that it is securely in place and can hold the intended weight without any wobbling or shifting.

- Test the Shelf’s Functionality: After reinstalling the wire shelf, place some lightweight items on it to ensure that it can function as intended. This will help you verify that the shelf is secure and can handle the load.

By carefully following these steps, you can ensure that the wire shelf is properly reinstalled and ready to be used again. Take your time during the installation process to ensure stability and functionality.

Lastly, don’t forget to periodically check the shelf’s stability and make any necessary adjustments or repairs to maintain its integrity over time.

Maintenance Tips

Proper maintenance of your wire shelf can extend its lifespan and keep it looking new and functional. Here are some essential maintenance tips to follow:

- Clean Regularly: Dust and debris can accumulate on the wire shelf over time, affecting its appearance and cleanliness. Regularly clean the shelf with a damp cloth or gentle cleaning solution to remove any dirt or grime.

- Avoid Overloading: Avoid placing excessive weight on the wire shelf, as it can strain the wires and potentially cause them to bend or break. Be mindful of the weight limits specified by the manufacturer.

- Check for Loose Connections: Periodically inspect the supports, brackets, and clips of the wire shelf. Ensure that they are securely attached and tighten any loose connections to maintain stability.

- Inspect for Rust or Corrosion: Check the wire shelf for any signs of rust or corrosion, especially in areas exposed to moisture. If you notice any rust, clean it off carefully with a rust remover and apply a protective coating to prevent further damage.

- Address Bent Wires: If you notice any wires that are bent or misshapen, gently straighten them with pliers or wire cutters. This will ensure that the shelf remains sturdy and can properly support items.

- Protect the Coating: If your wire shelf has a protective coating, avoid using abrasive cleaning materials or harsh chemicals that can damage it. Instead, use mild cleaning solutions that won’t compromise the coating’s integrity.

- Be Mindful of Sharp Edges: Even after cutting the wire shelf, there may still be sharp edges. Use caution when handling the shelf to avoid injury. If needed, use sandpaper or a file to smooth out any remaining sharp spots.

- Regularly Rearrange Items: To prevent localized wear and tear, periodically rearrange the items on your wire shelf. This will distribute the weight and ensure that no single area of the shelf is under constant strain.

By following these maintenance tips, you can keep your wire shelf in optimal condition, ensuring its longevity and functionality. Regular cleaning, inspections, and addressing any issues promptly will help you enjoy your wire shelf for years to come.